Device and method for cleaning glass substrate

A substrate and glass technology, applied in the field of devices for cleaning substrate glass, can solve problems such as insecurity, glass scratches, and difficulty in cleaning, and achieve the effects of reducing electrostatic voltage and reducing adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

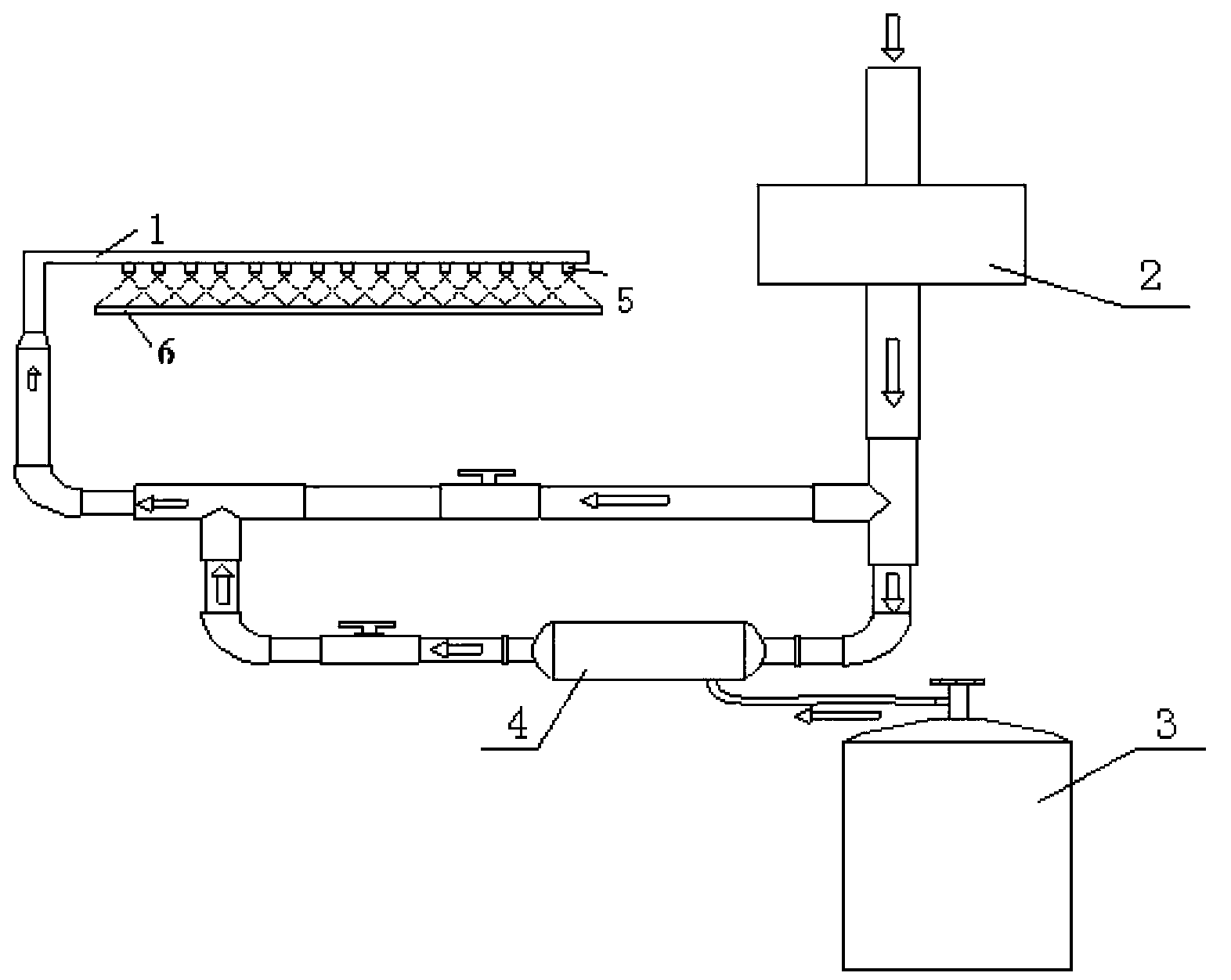

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

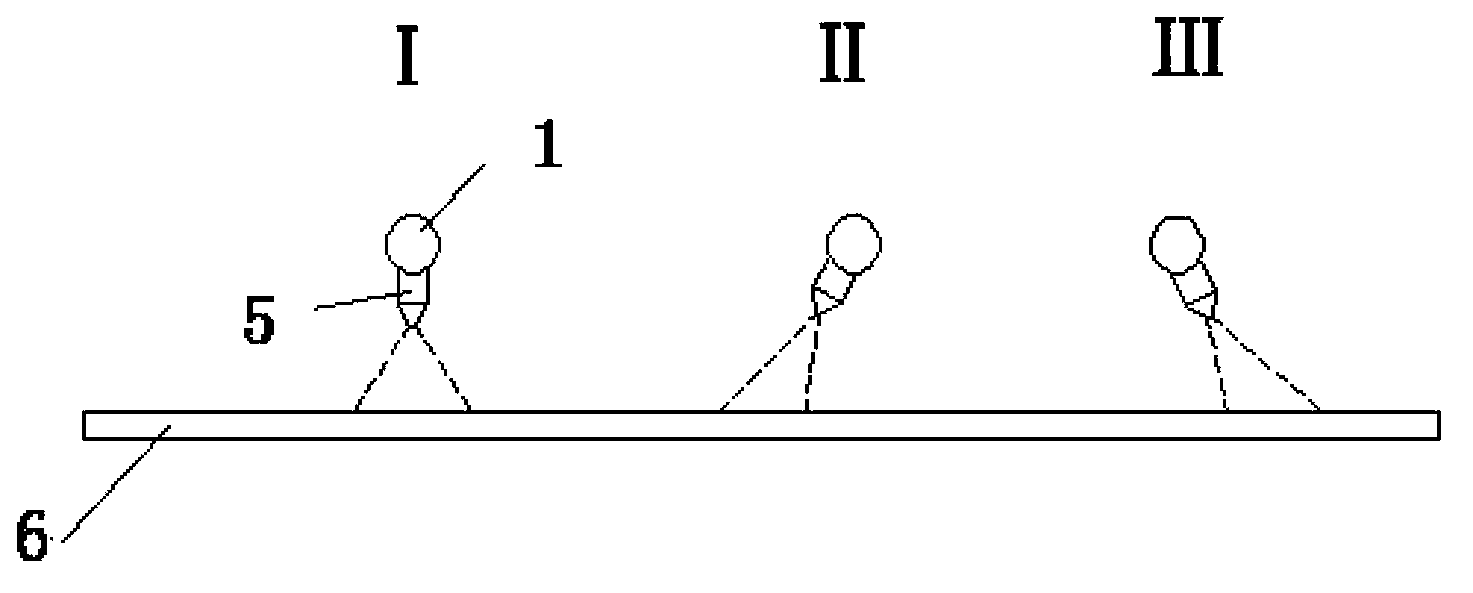

[0023] refer to figure 1 and figure 2 , the device for cleaning substrate glass according to the present invention includes pressure pump 2, CO 2 Storage tank 3, CO 2 Foam generator 4 and nozzle pipeline 1, the water inlet of described pressure pump 2 links to each other with described water source, and the water outlet of described pressure pump 2 is divided into two ways, wherein one way is connected with CO 2 The water inlet of foam generator 4 is connected, and the other way is connected with CO 2 The outlet of the foam generator 4 is connected with the inlet of the nozzle pipeline 1 after passing through the pipeline, and the CO 2 CO for foam generator 4 2 inlet with the CO 2 The outlet of the storage tank 3 is connected through a pipeline, and the wall of the nozzle pipeline 1 is provided with several nozzles 5, and the nozzle 5 is provided with an adjusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com