Catalyst for desorbing nitrogen oxides and carbon monoxide at low temperature and preparation method thereof

A nitrogen oxide and carbon monoxide technology, applied in the direction of metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. Short service life and other problems, to achieve the effect of simplifying industrial emission reduction process, simple composition, improving activity and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Catalyst preparation:

[0031] a) Coconut shell activated carbon was pickled with hydrochloric acid, washed with water, and dried at 110°C for 5h, and then the equal volume water absorption of activated carbon was measured;

[0032] b) At 22°C, weigh 10 g of activated carbon treated in step a), and prepare Cu (NO 3 ) 2 solution; put activated carbon into Cu(NO 3 ) 2 Immerse in the solution for 24h;

[0033] c) drying the activated carbon after step b) at 110° C. for 5 hours;

[0034] d) Calcining the dried coconut shell activated carbon in step c) at 300° C. for 3 hours to obtain a finished catalyst.

[0035] Catalyst activity detection: Simulated flue gas composition (volume fraction): NO / N 2 (5%, 20ml / min), NH 3 (5%, 8ml / min), O 2 (10ml / min) and balance gas N 2 (100ml / min), the gas flow is controlled by a rotameter, and the gas is mixed and passed into the reaction tube.

[0036] NO x The formula for calculating the removal efficiency is as follows:

...

Embodiment 2

[0044] Catalyst preparation:

[0045] a) Coconut shell activated carbon was pickled with hydrochloric acid, washed with water, and dried at 100°C for 6h, and then the equal volume water absorption of activated carbon was measured;

[0046] b) At 25°C, weigh 10 g of activated carbon treated in step a), and prepare Cu (NO 3 ) 2 solution; put activated carbon into Cu(NO 3 ) 2 Immerse in the solution for 12h;

[0047] c) drying the activated carbon treated in step b) at 80° C. for 7 hours;

[0048] d) Calcining the dried coconut shell activated carbon in step c) at 200°C for 5 hours to obtain a finished catalyst.

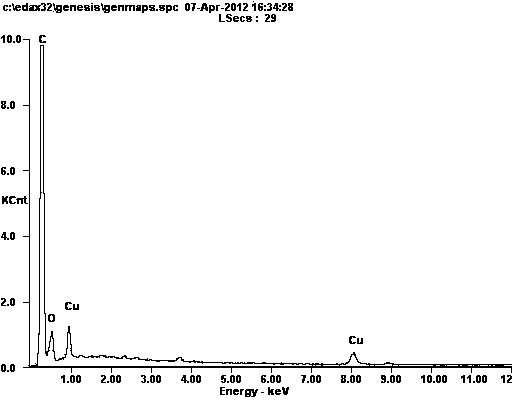

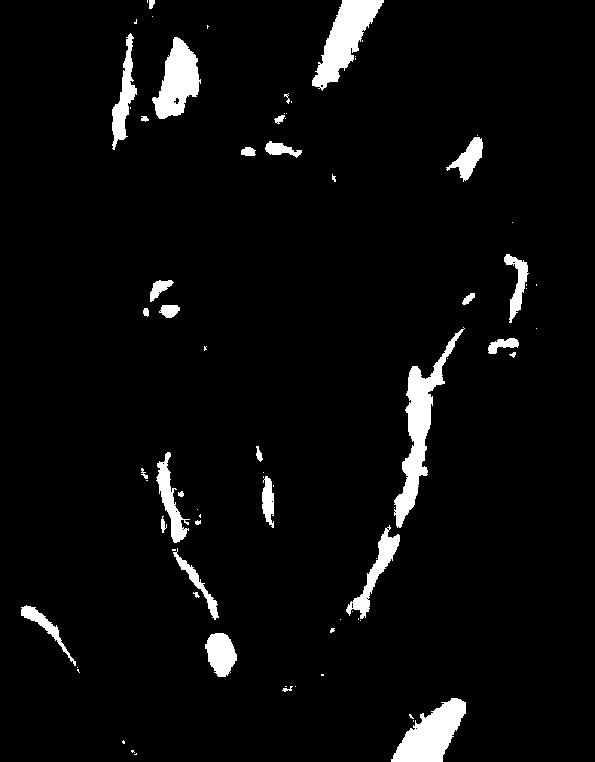

[0049] The content of each component of the catalyst prepared by the above method and the dispersion of CuO are as follows: figure 1 and figure 2 as shown, figure 1 Show that in the catalyst composition that this preparation method obtains: Cu element content is 5.04%, C element content is 86.69%, O element content is 8.27%, figure 2 It shows that CuO is unif...

Embodiment 3

[0054] Catalyst preparation:

[0055] a) Coconut shell activated carbon was pickled with hydrochloric acid, washed with water, and dried at 120°C for 6h, and then the equivalent volume water absorption of activated carbon was measured;

[0056] b) 35°C, weigh 10g of activated carbon treated in step a), and prepare Cu(NO 3 ) 2 solution; put activated carbon into Cu(NO 3 ) 2 Immerse in the solution for 72h;

[0057] c) drying the activated carbon treated in step b) at 110° C. for 8 hours;

[0058] d) Calcining the dried coconut shell activated carbon in step c) at 500° C. for 3 hours to obtain a finished catalyst.

[0059] Catalyst activity detection: Composition of flue gas and NO x The formula for calculating the removal rate of CO and CO is the same as in Example 1. Pack this catalyst in a quartz reaction tube, pass through simulated flue gas containing NO, and detect the NO concentration in the inlet and outlet gases at a reaction temperature of 275°C. x The remo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com