Method for preparing cold water dispersing type carotenoid micro-capsule powder without using organic solvent

A technology of carotene and organic solvents, which is applied in the field of preparation of cold-water dispersible carotenoid microcapsule powder without using organic solvents, which can solve the problems of complex preparation process, residual organic solvent dissolution, difficult production control, etc., and achieve a green and environmentally friendly process , No solvent residue, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Put 100g of lutein crystals, 11g of sucrose stearate, 2g of d-alpha tocopherol, 3g of glyceryl monolaurate, and 49g of gum arabic into 1000ml of water, heat up to 40°C, and stir until the crystals are dispersed and suspended uniformly to obtain leaf Lutein suspension; under the protection of nitrogen, the suspension is circularly ground with a sand mill for 120 minutes and homogenized, so that the crystal particles are crushed and suspended stably; the stable suspension of lutein crystals is passed through a pipeline heater, The temperature of the heater is 125±2°C, and the time is 25s, so that the suspended particles of the crystals are finer and an emulsion is formed. The particle size of the lutein crystals in the emulsion is 260nm (D50). After cooling the emulsion to 60°C, add 400g of gum arabic, Stir 100g of maltoligosaccharides until completely dissolved, spray-dry the obtained emulsion into a dry powder, and then further agglomerate and granulate to obtain a cold-...

Embodiment 2

[0042] Put 123g of β-carotene crystals, 10g of polysorbate 80, 6g of glyceryl monostearate, 96g of modified starch (Hi Cap100 provided by National Starch USA), 6gdl-α tocopherol in 2200ml of water, and heat up to 46°C , stirred until the crystals are uniformly dispersed and suspended to obtain a suspension of β-carotene; under the protection of nitrogen, the suspension was circularly ground with a ball mill for 120 minutes to homogenize, so that the crystal particles were crushed and suspended stably; the β-carotene was The stable suspension of crystals passes through the pipeline heater. The temperature of the heater is 113°C and the time is 43s to make the suspended particles of the crystals finer and form an emulsion. After 40°C, add 620g of modified starch and 70g of maltooligosaccharide and stir until completely dissolved. The resulting emulsion is spray-dried into a dry powder, and finally cold water dispersible β-carotene microcapsule powder is obtained, with a β-caroten...

Embodiment 3

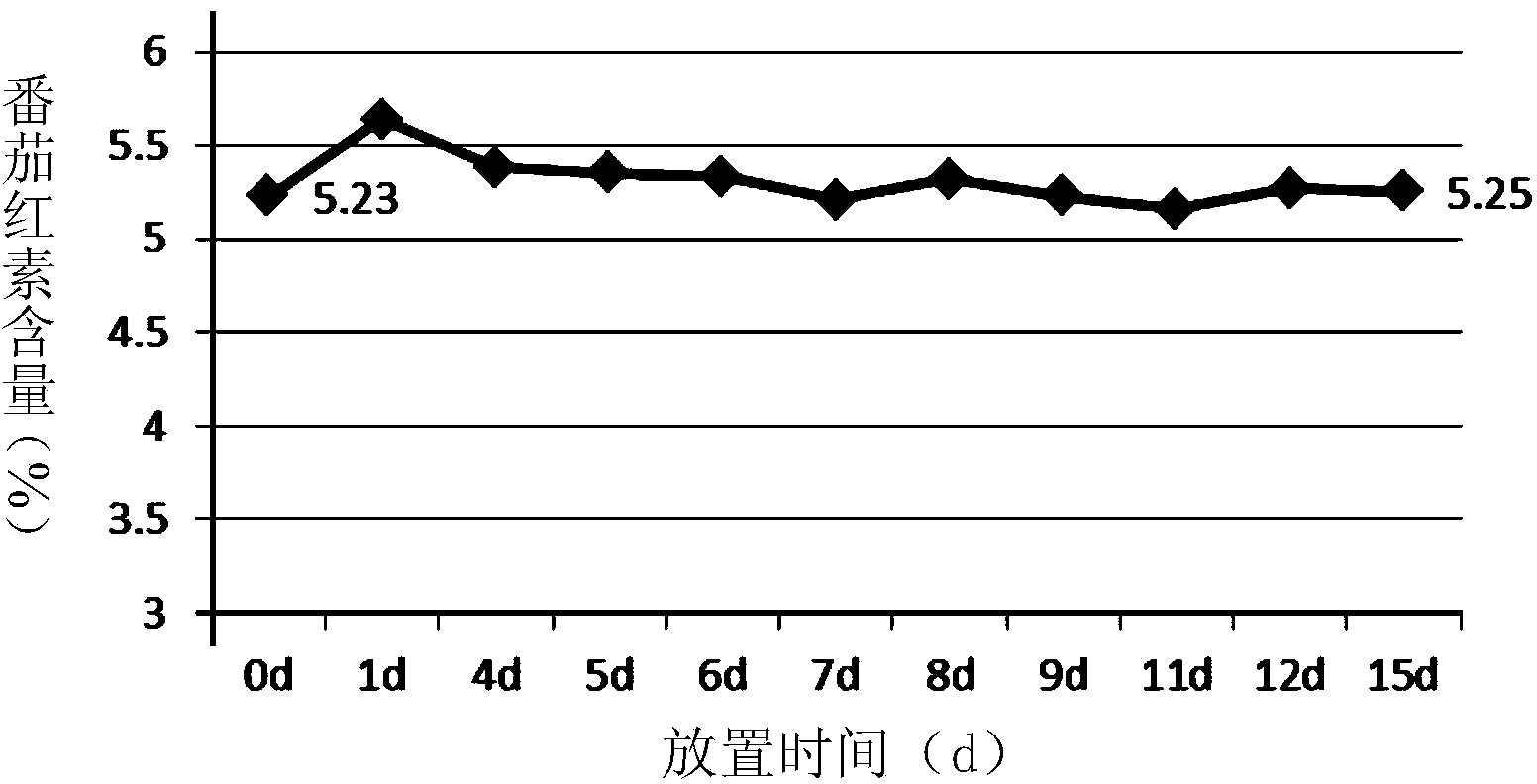

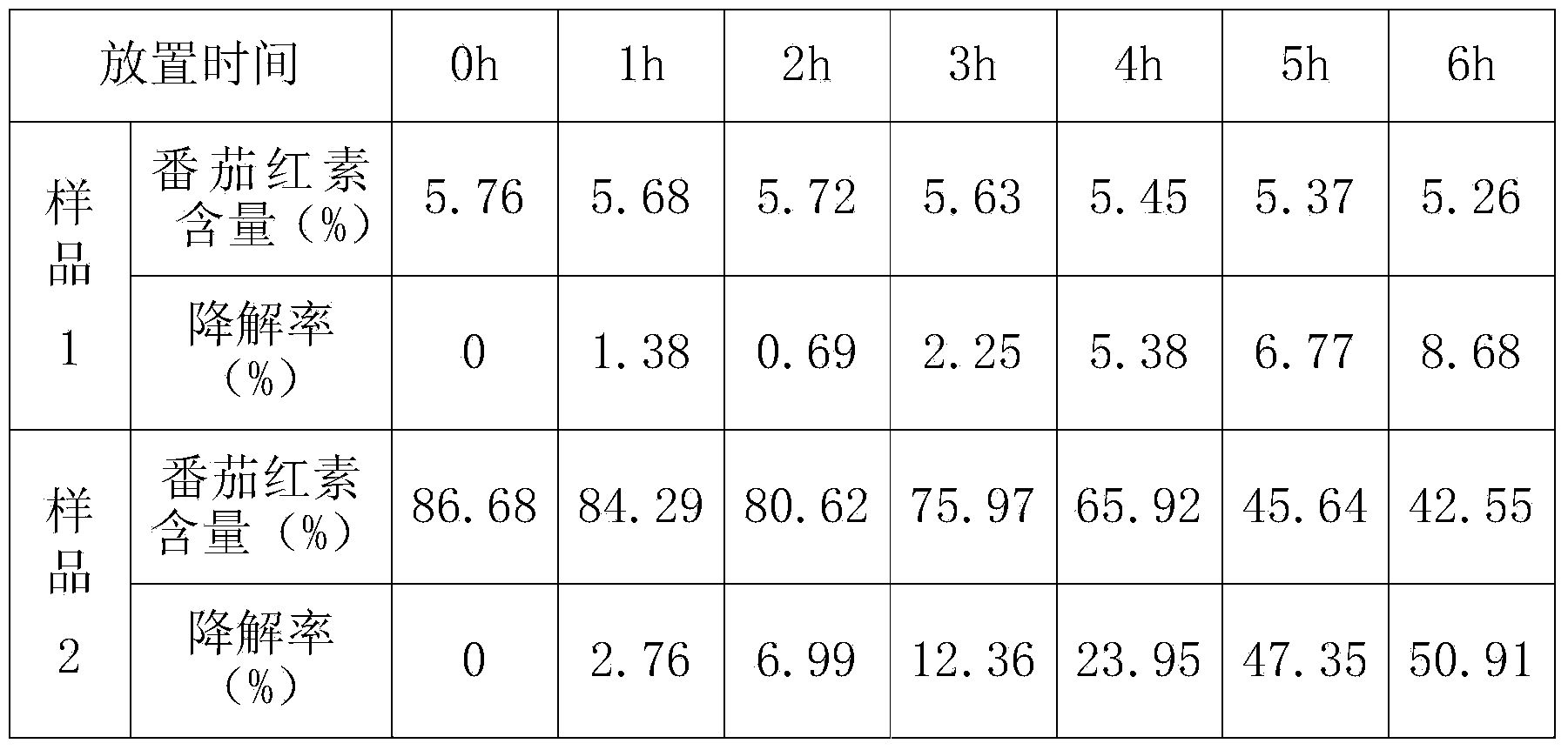

[0044] Put 62g of lycopene crystals, 5g of polyglycerol fatty acid esters, 3g of monoglyceryl and distearic acid glycerides, 9g of mixed tocopherols, and 113g of modified starch (Hi Cap100 provided by National Starch USA) in 1900ml of water and heat up to 43°C , stirred until the crystals were uniformly dispersed and suspended to obtain a lycopene crystal suspension; under the protection of nitrogen, the suspension was circulated and ground with a sand mill for 120 minutes to homogenize, so that the crystal particles were crushed and suspended stably; the lycopene The stable suspension of lycopene passes through the pipeline heater, the temperature of the heater is 123°C, and the time is 35s, so that the suspended particles of the crystal are finer and an emulsion is formed. The particle size of the lycopene crystal in the emulsion is 380nm (D50), and the temperature of the emulsion is cooled to After 40°C, add 790g of modified starch and 170g of maltooligosaccharide and stir u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com