Porous semi-degraded hydrogel material used for cartilage repair and preparation method thereof

A porous hydrogel and cartilage repair technology, applied in medical science, prostheses, etc., can solve the problems that the connection between the implant and the surrounding cartilage tissue cannot be improved, and achieve the effect of ensuring the mechanical strength and solving the connection problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

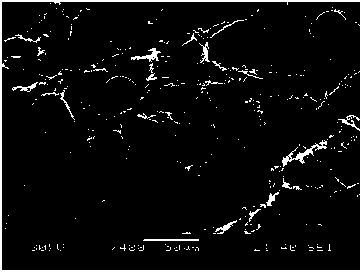

Image

Examples

Embodiment 1

[0025] (1) PLGA microspheres were prepared by emulsification-solvent evaporation method. The method described is to weigh 480mg of PLGA solid particles, put it into 16ml of acetone and dichloromethane mixture solution (1:3 by volume), and ultrasonically dissolve it completely to obtain a uniform PLGA solution. The obtained solution was added dropwise into 10 times the volume of 2wt% low-viscosity PVA solution with a dropper, and the PVA solution was magnetically stirred at a speed of 1000 r / min and placed in an ice-water bath. After the dropwise addition, the solution was sealed, taken out from the ice-water bath, and continued to stir on a magnetic stirrer at a speed of 1000 / min for 10 min. Then, peel off the sealing film, and continue to stir at a speed of 400r / min for 12 hours, so that the acetone and dichloromethane solvents are fully volatilized. Finally, PLGA microspheres were obtained by suction filtration, washing and freeze-drying.

[0026] (2) Weigh PVA and PVP pow...

Embodiment 2

[0031] (1) PLGA microspheres were prepared by emulsification-solvent evaporation method. The method described is to weigh 480mg of PLGA solid particles, put it into 16ml of acetone and dichloromethane mixture solution (1:3 by volume), and ultrasonically dissolve it completely to obtain a uniform PLGA solution. The obtained solution was added dropwise into 10 times the volume of 2wt% low-viscosity PVA solution with a dropper, and the PVA solution was magnetically stirred at a speed of 1000 r / min and placed in an ice-water bath. After the dropwise addition, the solution was sealed, taken out from the ice-water bath, and continued to stir on a magnetic stirrer at a speed of 1000 / min for 10 min. Then, peel off the sealing film, and continue to stir at a speed of 400r / min for 12 hours, so that the acetone and dichloromethane solvents are fully volatilized. Finally, PLGA microspheres were obtained by suction filtration, washing and freeze-drying.

[0032] (2) Weigh PVA and PVP pow...

Embodiment 3

[0037](1) PLGA microspheres were prepared by emulsification-solvent evaporation method. The method described is to weigh 480mg of PLGA solid particles, put it into 16ml of acetone and dichloromethane mixture solution (1:3 by volume), and ultrasonically dissolve it completely to obtain a uniform PLGA solution. The obtained solution was added dropwise into 10 times the volume of 2wt% low-viscosity PVA solution with a dropper, and the PVA solution was magnetically stirred at a speed of 1000 r / min and placed in an ice-water bath. After the dropwise addition, the solution was sealed, taken out from the ice-water bath, and continued to stir on a magnetic stirrer at a speed of 1000 / min for 10 min. Then, peel off the sealing film, and continue to stir at a speed of 400r / min for 12 hours, so that the acetone and dichloromethane solvents are fully volatilized. Finally, PLGA microspheres were obtained by suction filtration, washing and freeze-drying.

[0038] (2) Weigh PVA and PVP powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com