A method of forming a capacitor structure, and a silicon etching liquid used in this method

A capacitor structure and etching solution technology, applied in capacitors, capacitor manufacturing, chemical instruments and methods, etc., can solve the problems of corrosion of electrodes or other components, and achieve the effect of responding to changes and extension of application time and improving productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

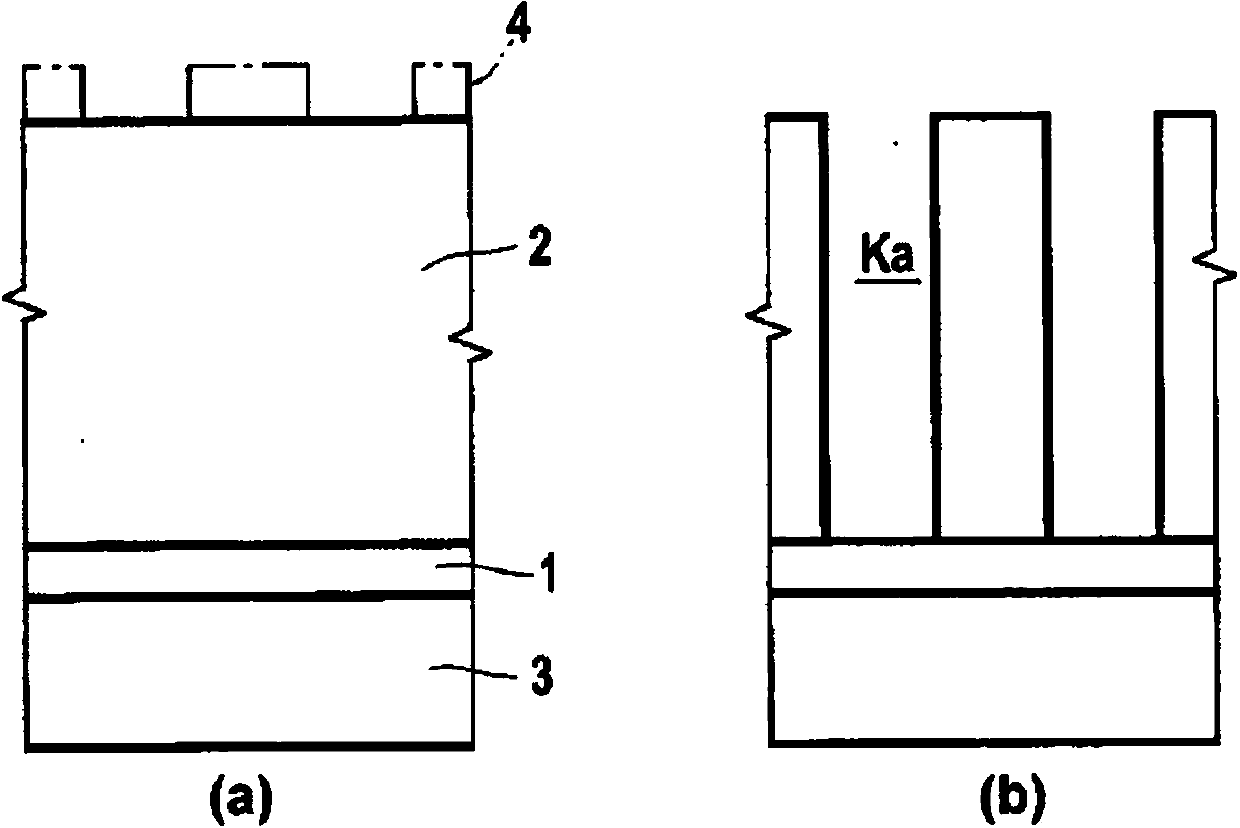

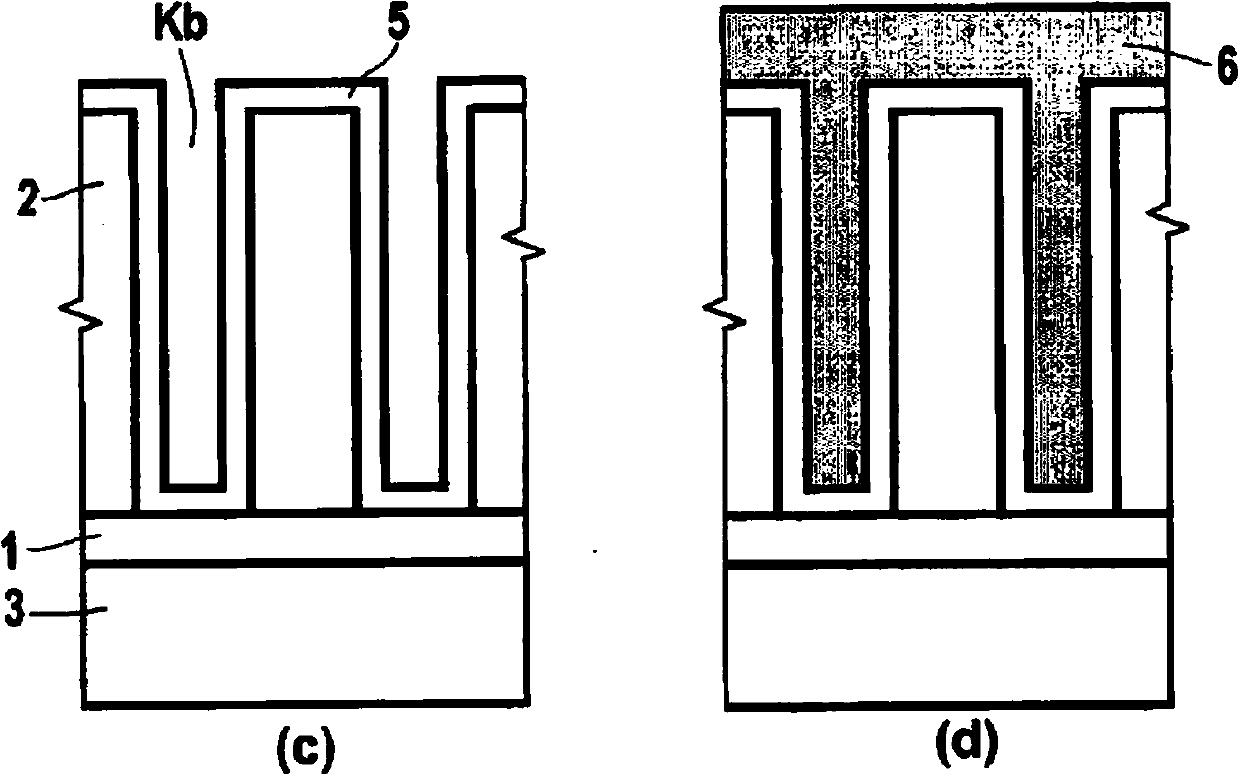

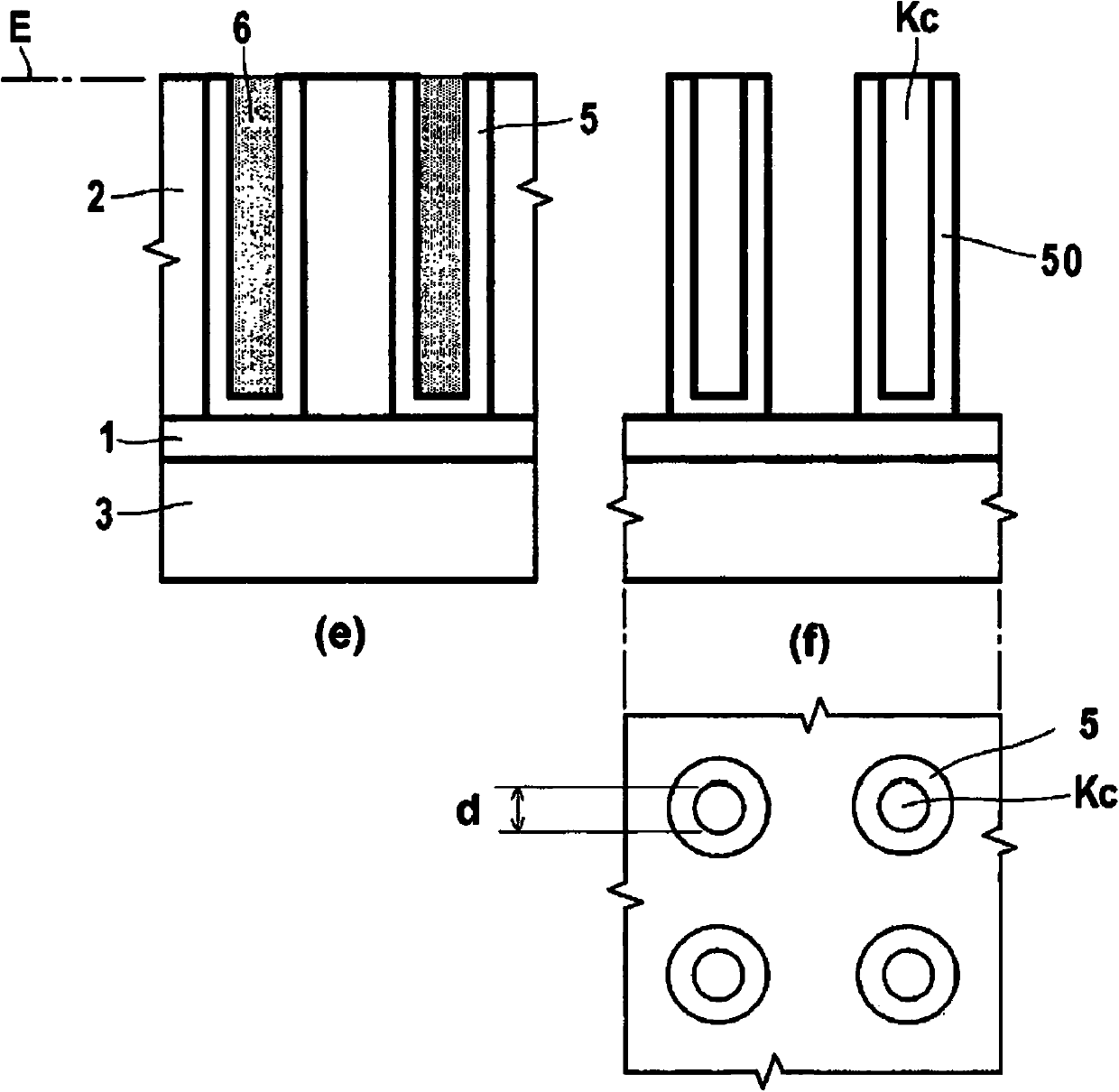

Method used

Image

Examples

example 1 and comparative example 1

[0088] The ingredients shown in Table 1 below were mixed in the composition (% by mass) shown in the following formulation to prepare an etching solution.

[0089]

[0090] Test wafer: A wafer was provided in which a polycrystalline silicon film with a thickness of 500 nm or an amorphous silicon film with a thickness of 500 nm was formed on single-crystal silicon. The wafer was etched with a sheet type etching instrument (POLOS (trade name), manufactured by SPS-Europe B.V.) under the following conditions, and an evaluation test was performed. A wafer with a diameter of 300nm was used, and the evaluation was done by comparing the etch rates at the circumference of two concentric circles, one of which was centered at the center of the wafer and had a radius of 10mm (measured center etch rate: Rc), Another circle 30 mm from the edge (measured edge etch rate: Re).

[0091] Reagent liquid temperature: 80°C

[0092] Discharge volume: 1L / min

[0093] Wafer rotation speed: 500rp...

example 2 and comparative example 2

[0109] 10% by mass of various solvents shown in Table 2 below, 10% by mass of TMAH and 5% by mass of hydroxylamine were added to prepare reagent liquids, all of which had a pH of 12 or more. Using the etching solution thus prepared, an etching test was performed in the same manner as in Example 1 (the etching rate was measured at 10 mm from the center). In addition, the contact angles of silicon and TiN were measured at room temperature. These results are presented in Table 2 below.

[0110]

[0111] From the above results, it can be seen that the contact angle of the etching solution to which the solvent was added was smaller than that of the etching solution to which no solvent was added, and it was confirmed that the wettability was improved. That is, since the enhancement of wettability is confirmed, it can be presumed that silicon residue is less likely to be generated in the capacitor. Furthermore, the improvement in the removability of such silicon residues brings ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com