Li2S-P2S5-TiS2 amorphous electrolyte material

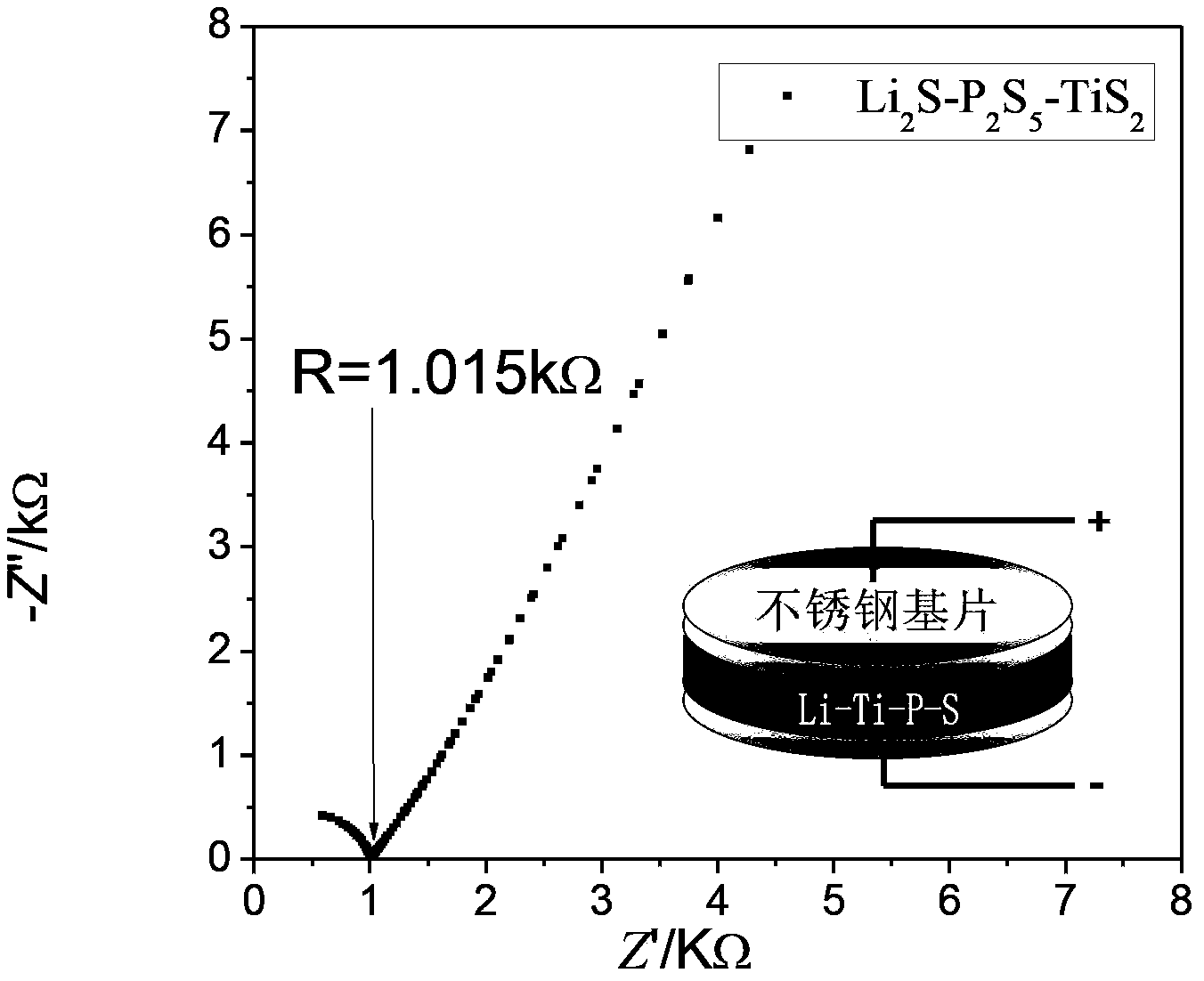

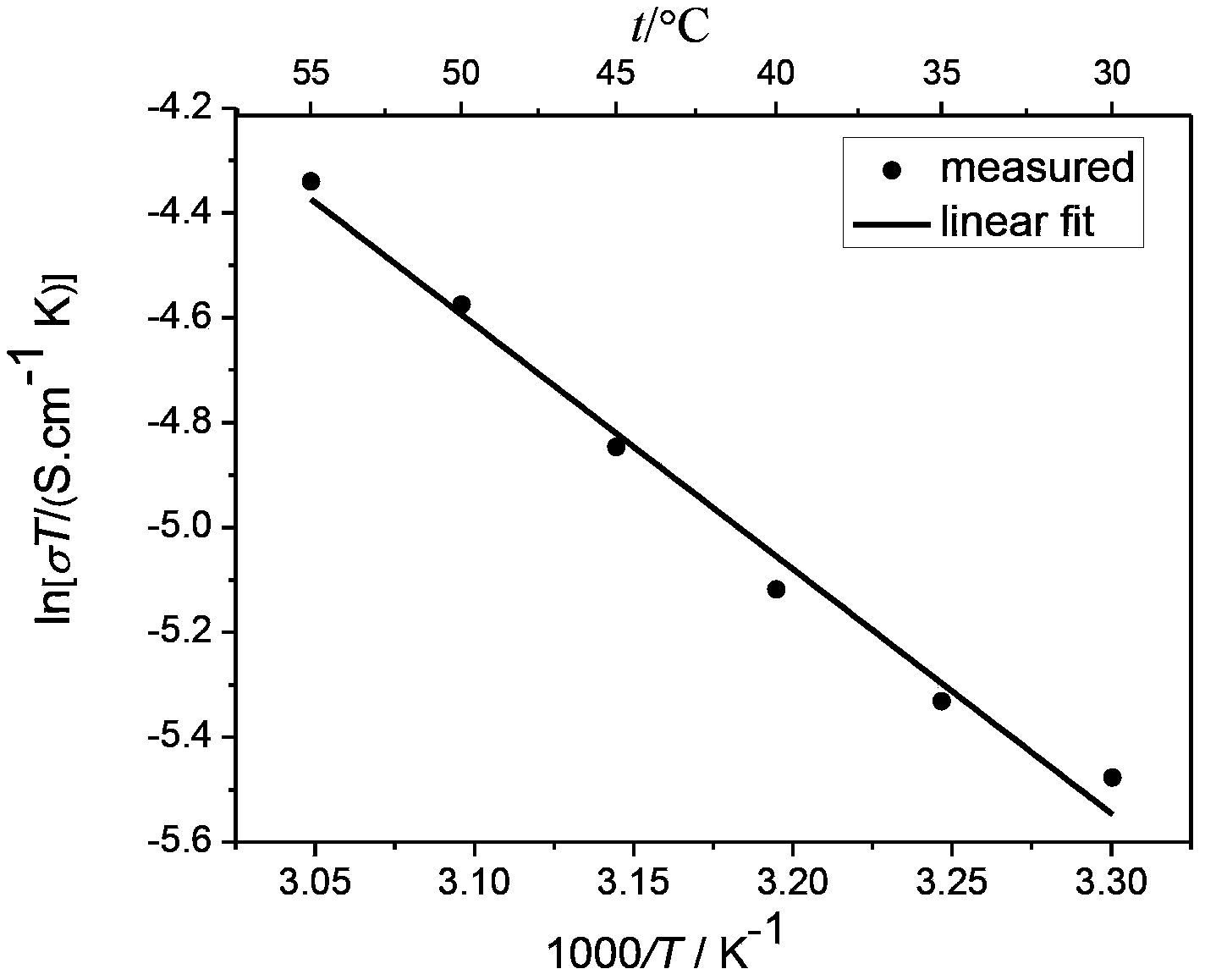

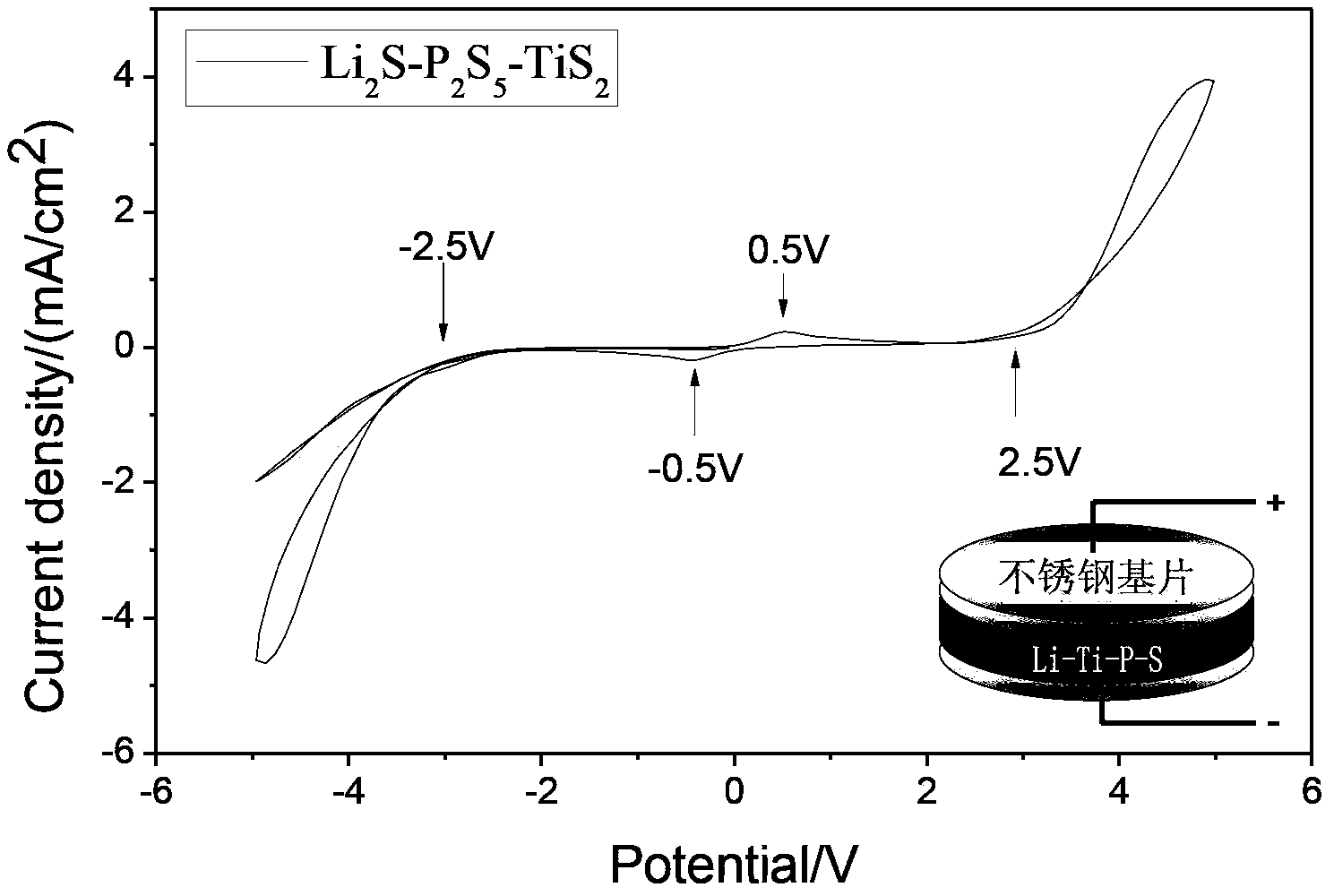

A technology of li2s-p2s5-tis2 and electrolyte materials, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of insufficient electrochemical window, poor mechanical strength, and large interface impedance, and achieve mild and high reaction conditions. Room temperature ionic conductivity, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] A kind of Li 2 S-P 2 S 5 -TiS 2 It is an amorphous electrolyte material, and the electrolyte material is prepared by the following method:

[0024] Before the reaction, select three kinds of agate balls with large (diameter 10mm), medium (diameter 8mm) and small (diameter 6mm) and a single solvent in the ball mill jar, among which the large, medium and small agate balls are mixed according to the ratio of 5:7:10 The quantity ratio is mixed. Clean the agate balls three times, each time milling the ball mill jar in a solvent at a speed of 300rpm for 30-60 minutes, or repeat several times until the agate balls are cleaned; finally, dry the ball mill jar and the agate balls for later use. The solvents selected for each cleaning are detergent, deionized water, and absolute ethanol in sequence, and the solvent level is lower than 2 / 3 of the volume of the ball mill tank.

[0025] (1) High energy ball milling reaction:

[0026] In a glove box with argon atmosphere protect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Effective area | aaaaa | aaaaa |

| Ionic conductivity at room temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com