Dual-component amyl butyrate compound type ultra-low temperature drilling fluid for polar regions

An amyl butyrate, two-component technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of resource pollution, unsuitable technology, easy blockage in the hole, etc., and achieves high chemical stability, Expand the scope of application, the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

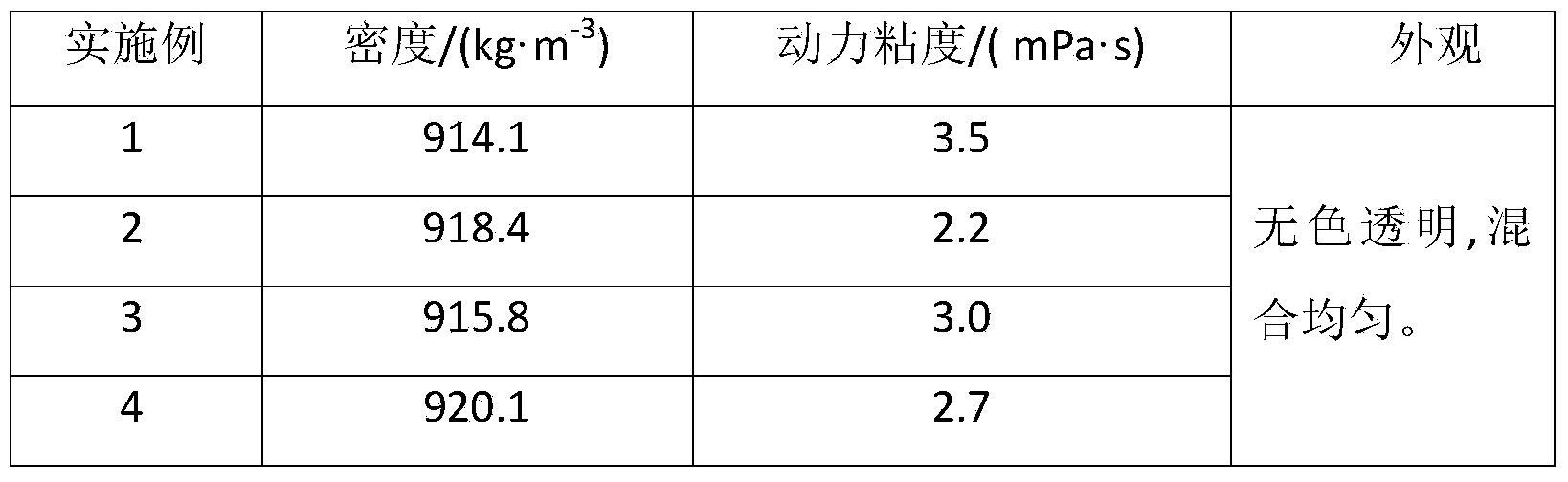

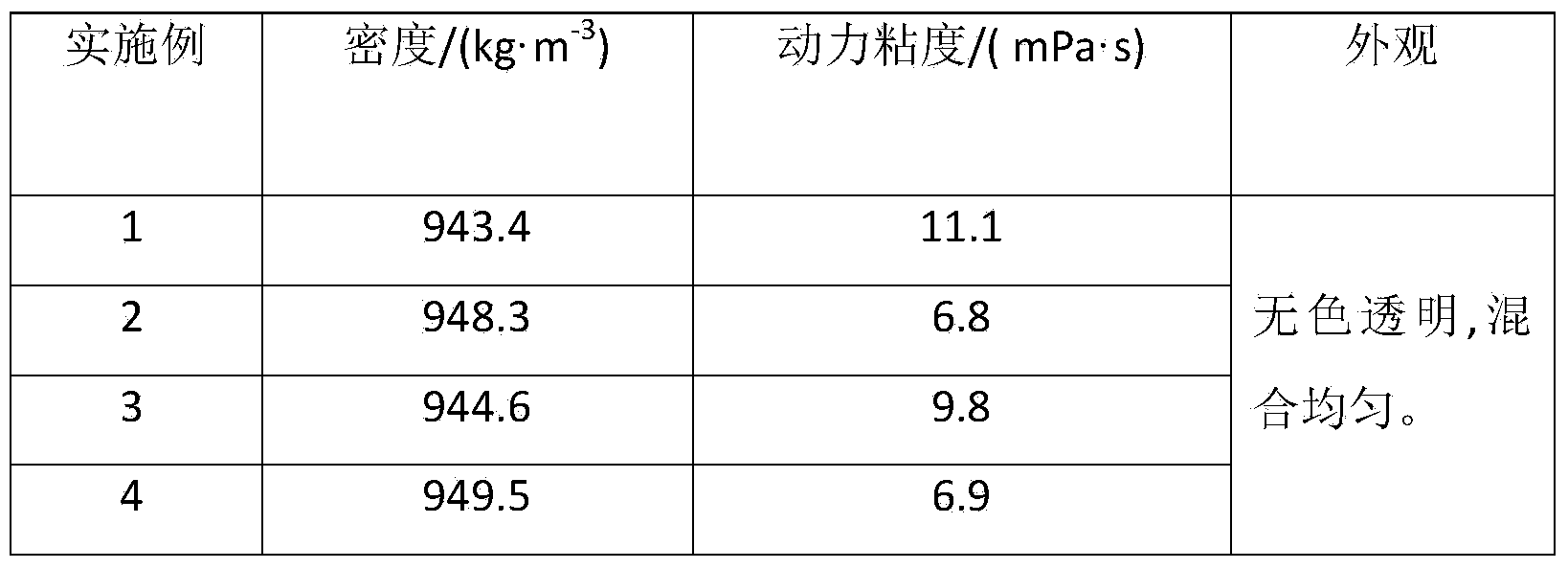

Embodiment 1

[0021] Mix 200g of ethyl butyrate and 600g of amyl butyrate to prepare two-component polar ester-based ultra-low temperature drilling fluid 1.

Embodiment 2

[0023] After mixing 400g of ethyl butyrate and 400g of pentyl butyrate, a two-component polar ester-based ultra-low temperature drilling fluid 2 was prepared.

Embodiment 3

[0025] After mixing 200g of propyl propionate and 600g of amyl butyrate, a two-component polar ester-based ultra-low temperature drilling fluid 3 was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com