Method for synthesizing aliphatic nano organic titanium polyaspartic acid ester and paints thereof

An aspartate, nano-organic technology, applied in epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve problems such as difficulty in meeting special technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

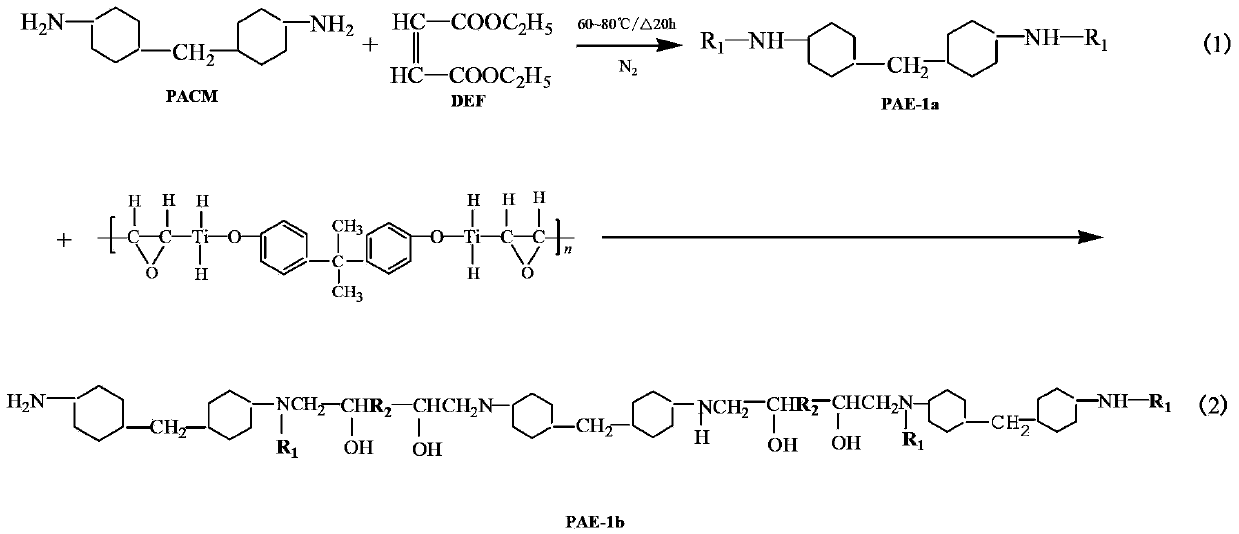

[0044] 1. Synthesis of nano-organotitanium polyaspartate (T-PAEs-A)

[0045] Step 1: Weigh 500g of 4,4'-diaminocyclohexylmethane (PACM≥98%), add it to a synthesis device with mechanical stirring, and fill it with N 2Evacuate the air, then raise the temperature to 60°C, control the temperature, slowly add 610g DEF (diethyl maleate) dropwise with a titration funnel, after the drop, raise the temperature from 60°C to 80°C, stop heating, and carry out Michael addition reaction. The whole reaction process was kept at a constant temperature of 80°C for 20 hours. Obtain the intermediate product PAE-1a for subsequent use;

[0046] Step 2: Prepare nano-organic titanium precursor oligomer (HTH) according to the method published in the invention patent ZL200810029936.1 "Nano-organic titanium polymer and its coating and manufacturing method", and add 850g of it to PAE-1a by weighing in excess , heated to 100-120° C. for 2 hours, cooled to room temperature, and the product T-PAEs-A (that...

Embodiment 2

[0048] Synthesis of aliphatic nano-organotitanium polyaspartate (T-PAEs-B):

[0049] The method is the same as T-PAEs-A, except that PACM is replaced by Laromin-C260 with the same quality, and other conditions are the same.

[0050] T-PAEs / A and T-PAEs / B are collectively referred to as aliphatic nano-organotitanium polyaspartate.

Embodiment 3

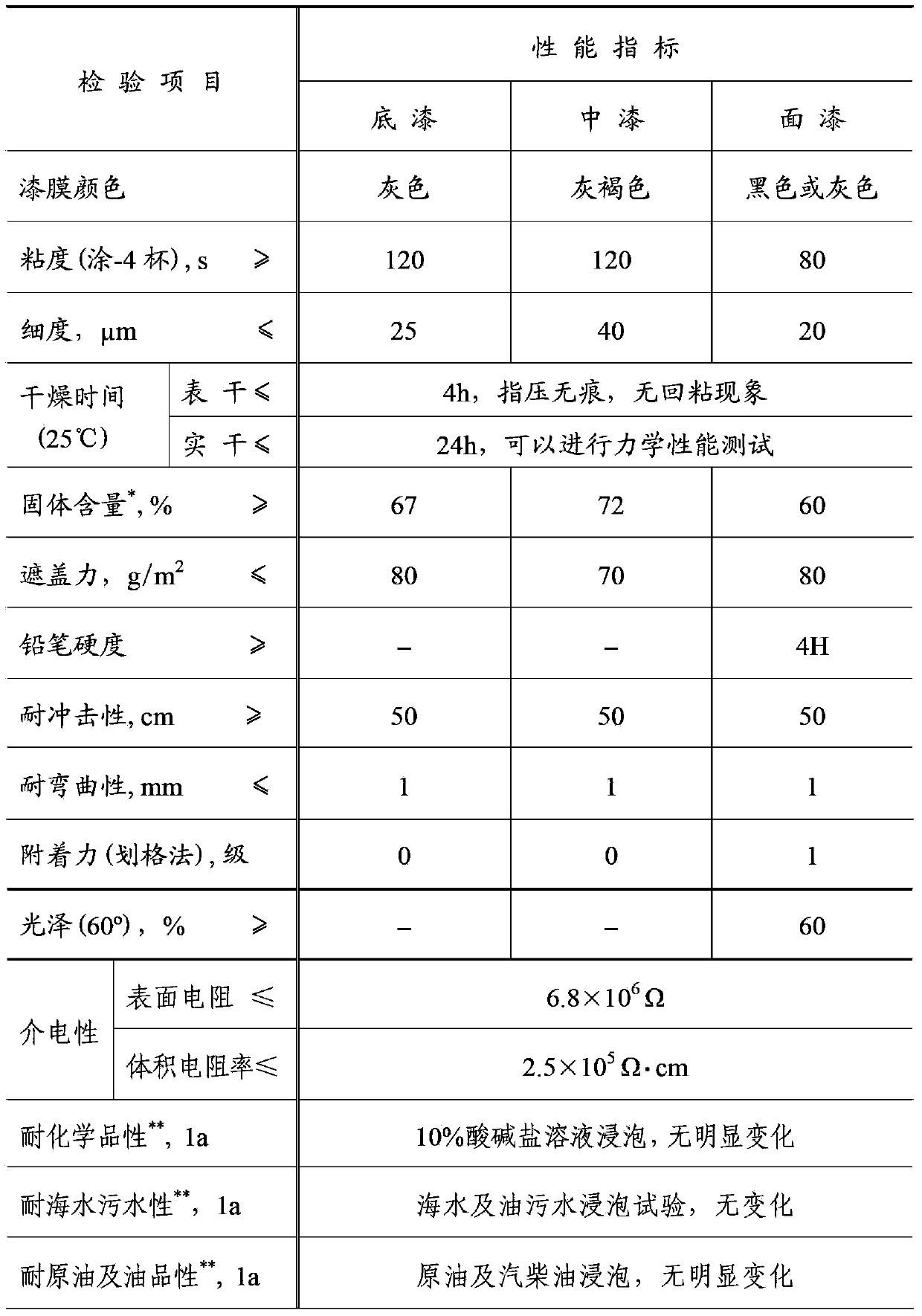

[0052] A preparation method of nano organic titanium marine heavy-duty anti-corrosion coatings, including the preparation of component A and the preparation of component B; wherein, the preparation of component A includes the preparation of primer, the preparation of intermediate paint and the preparation of topcoat The preparation of the B component also includes the preparation of the primer, the preparation of the intermediate paint and the preparation of the topcoat; the specific steps are as follows:

[0053] 1) The preparation of the primer of component A: Weigh 30 parts of aliphatic nano-organic titanium polyaspartate, 15 parts of 128 epoxy resin, 8 parts of liquid nitrile rubber, BYK-wetting and dispersing agent according to parts by mass 0.5 parts, 1.5 parts of liquid anti-sedimentation agent, 0.5 parts of BYK-defoamer, 0.5 parts of BYK leveling agent, 1 part of silane coupling agent, 15 parts of zinc phosphochromate, placed in a high-speed dispersing machine to disper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com