Lanthanum flint optical glass and preparation method thereof

A technology of optical glass and flint, which is applied in the field of lanthanum flint optical glass and its preparation, can solve problems such as no cost advantage, and achieve the effects of good crystallization performance, excellent chemical stability, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

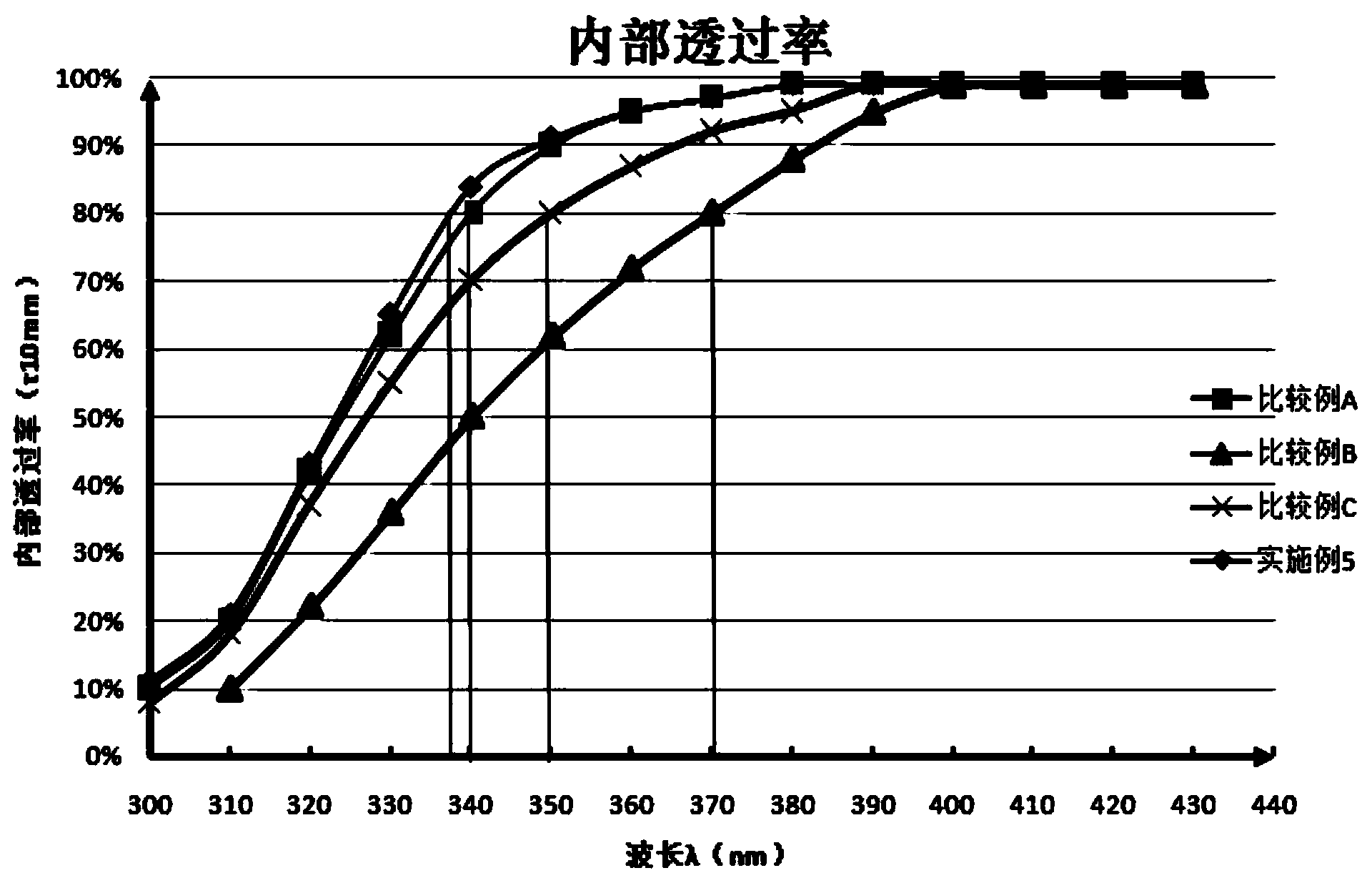

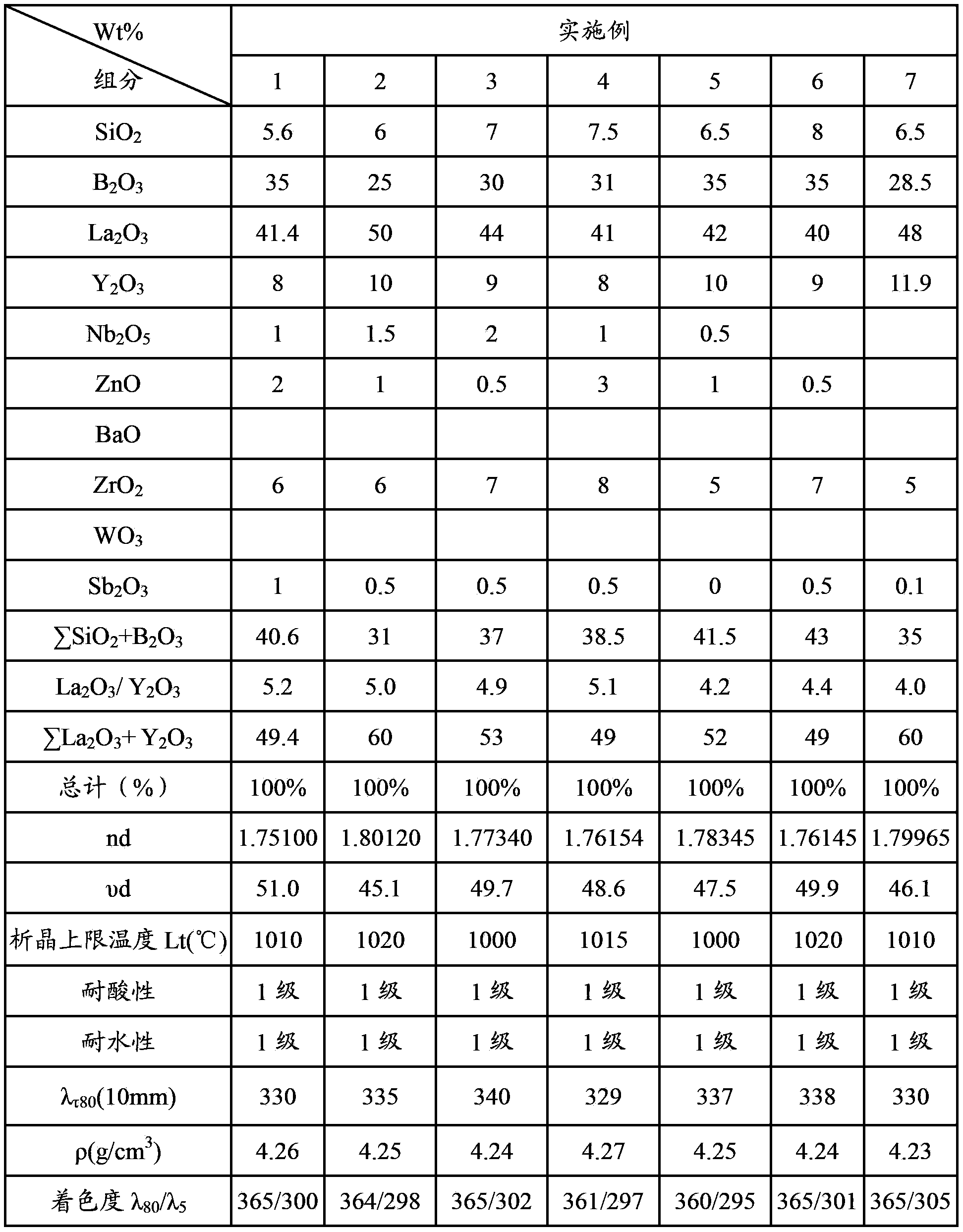

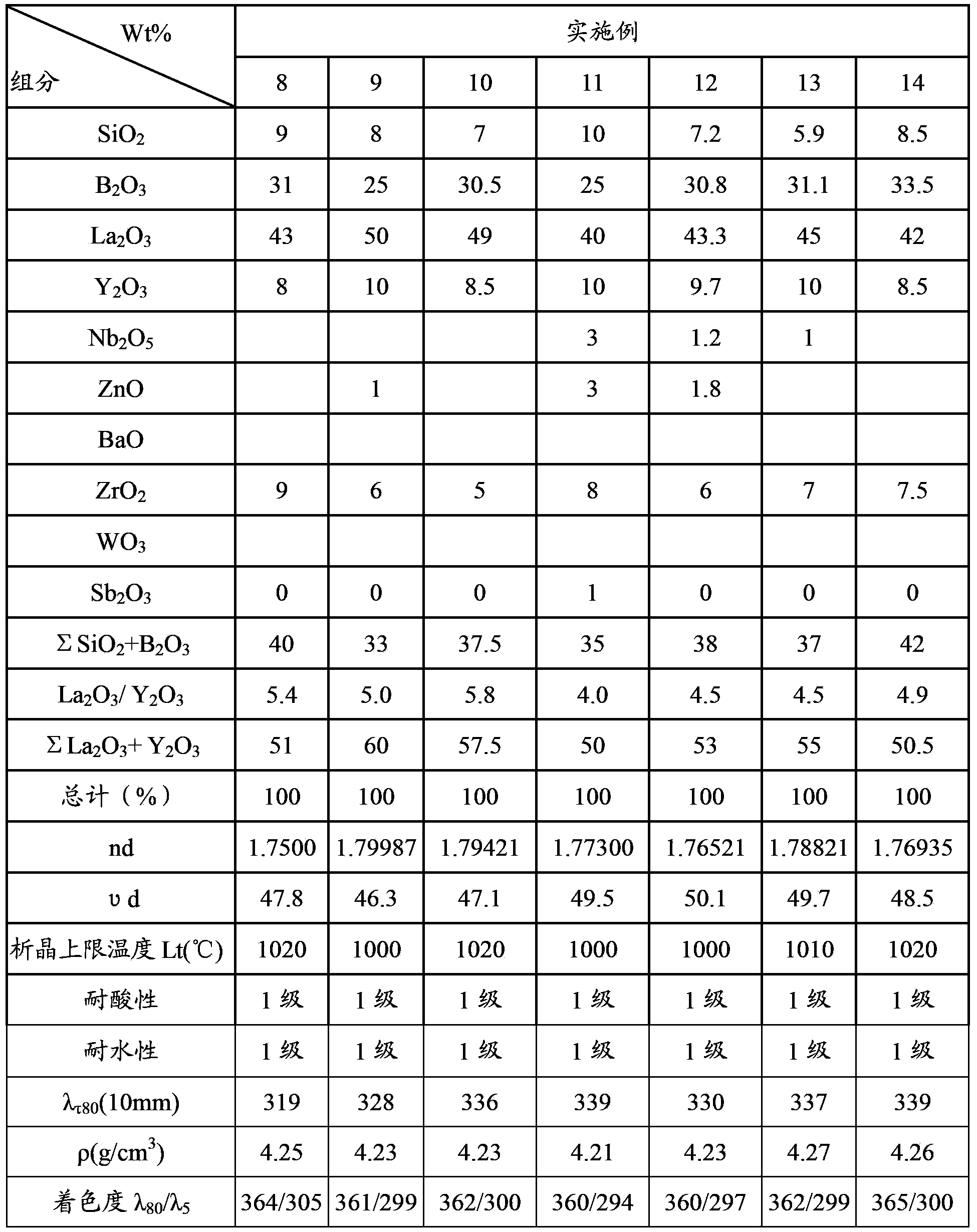

[0042] Examples 1 to 14 listed in the following Table 1 and Table 2 are used to illustrate the present invention to obtain lanthanum flint optics with a refractive index (nd) between 1.75 and 1.80 and an Abbe number (υd) between 44 and 51. Specific embodiments of glass. Comparative Examples A, B and C are comparative embodiments having a refractive index between 1.75-1.80 and an Abbe number between 44-51.

[0043] Calculate, weigh, and mix these raw materials in a V-shaped mixer according to the ratios provided in Table 1, and mix for 13-20 minutes at 10-20 revolutions per minute. Mix the prepared batches evenly and put them into the smelting device within 8 hours (in view of the application requirements of the present invention, the smelting device needs to use a platinum crucible), and then take appropriate stirring, clarification, and homogenization at 1250 ° C ~ 1350 ° C, And in the process of glass melting, dry air with a dew point not higher than -40°C needs to be intro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com