Combined cutter and pipe cutting method

A cutting knife and blade technology, which is applied in the pipe cutting machine double-knife combined cutting knife, and the pipe cutting field of the above-mentioned combined cutting knife, can solve the problems of iron filings splashing, low processing efficiency, and low service life of saw blades, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

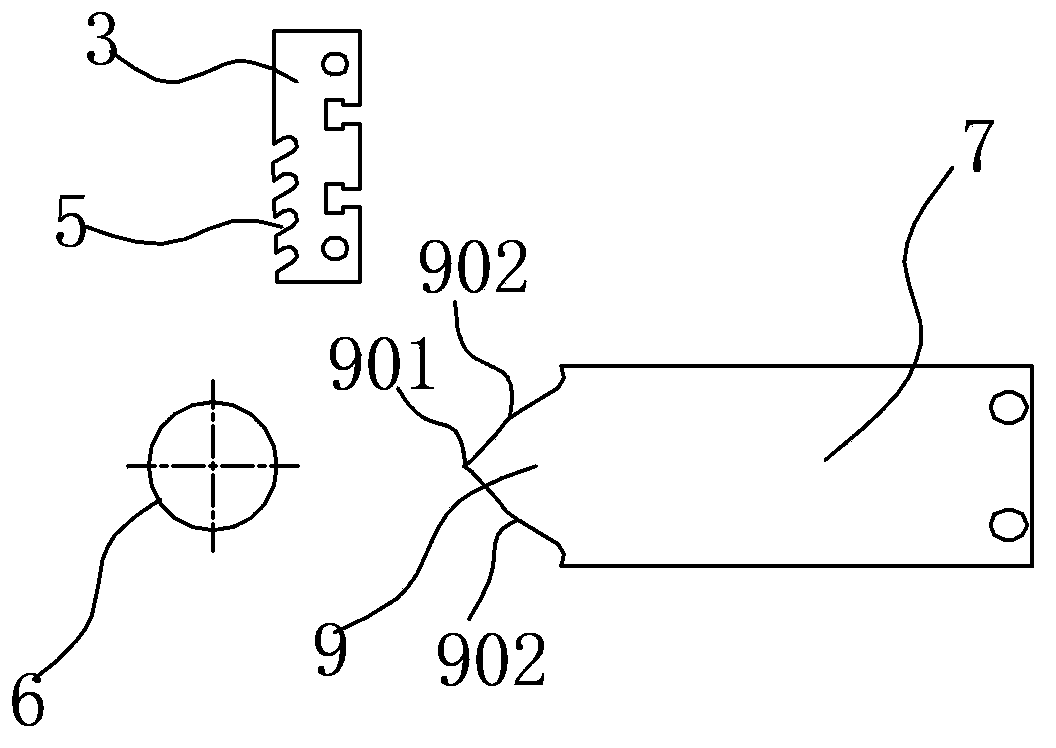

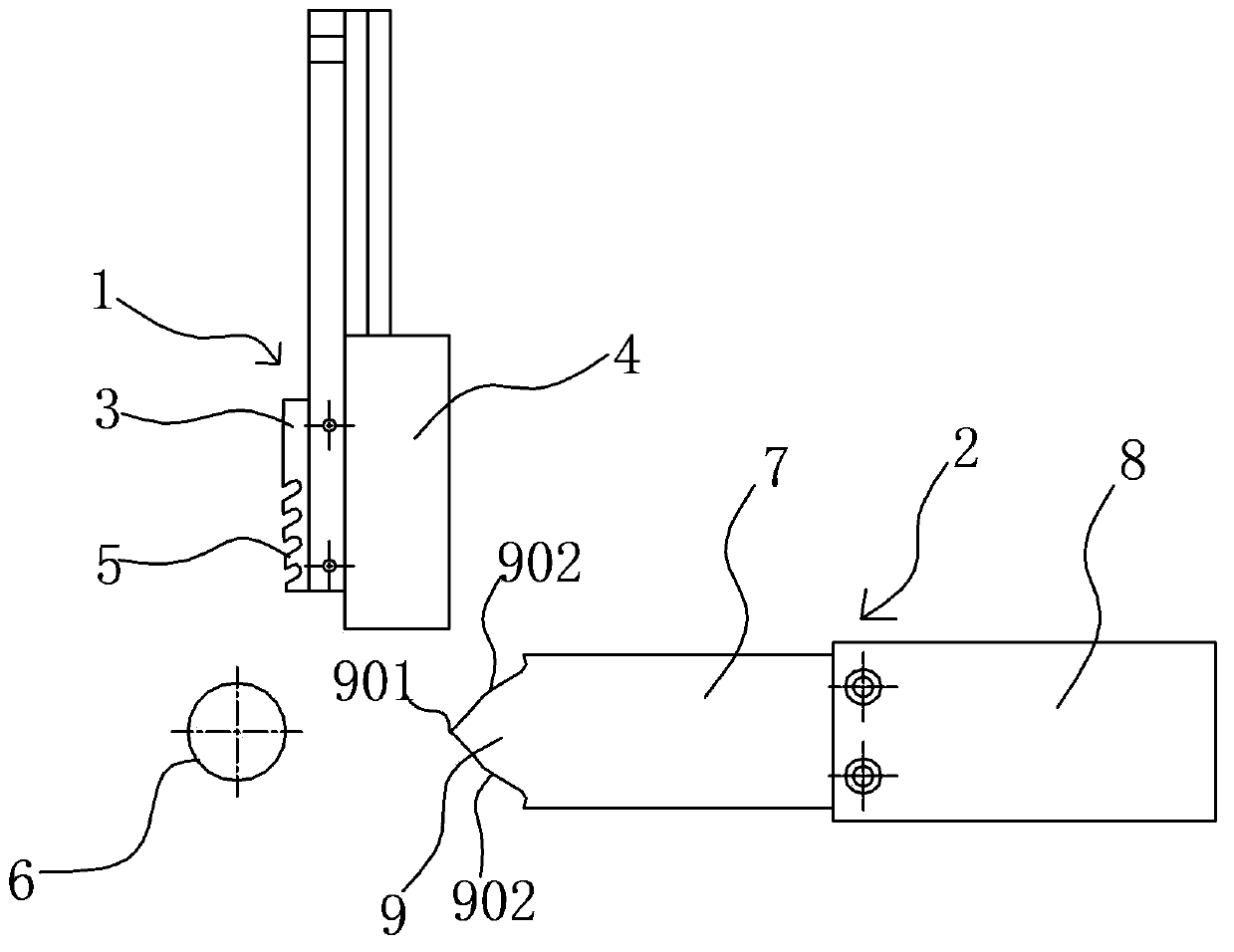

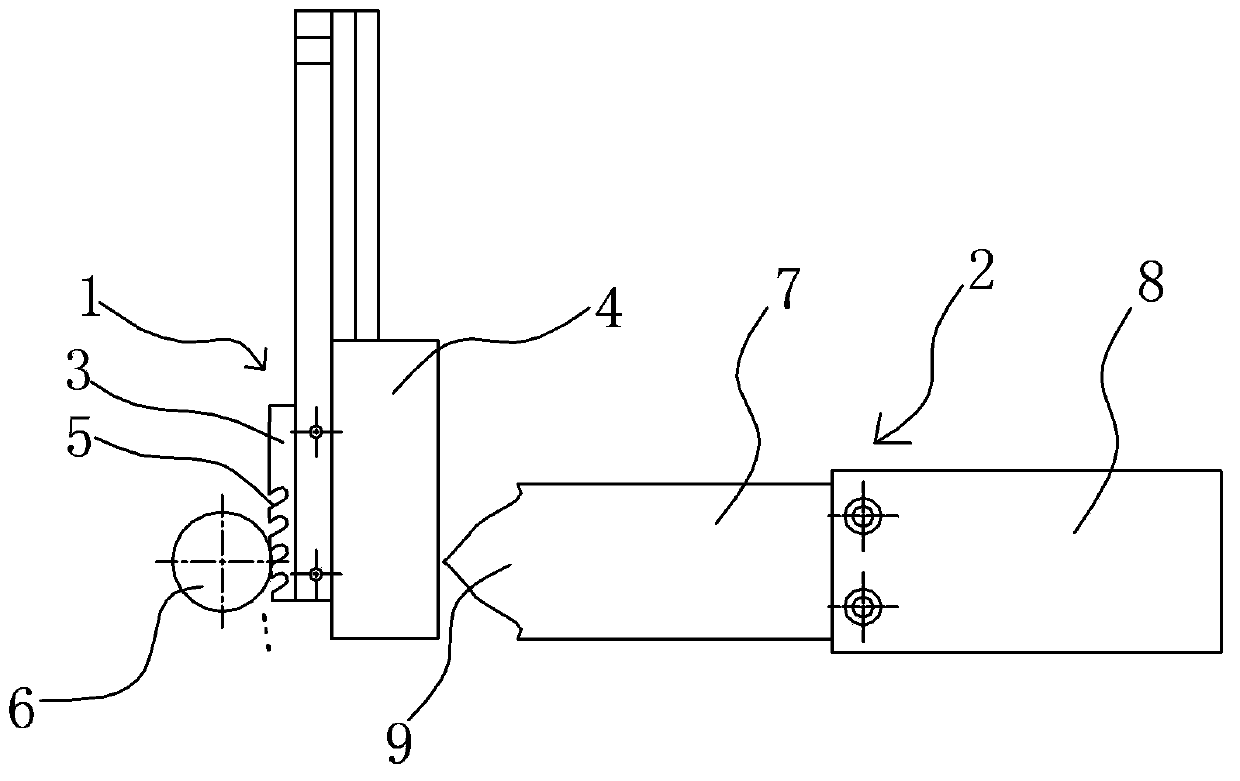

[0023] With reference to the accompanying drawings, a combined cutter includes a vertical cutter 1 and a horizontal cutter 2, and the vertical cutter 1 and the horizontal cutter 2 act alternately. The vertical cutter 1 includes a vertical blade 3 and a vertical fixing seat 4, and the vertical blade 3 and the vertical fixing seat 4 are fixed together by bolts. The vertical blade 3 is a long broach, and the lower left side of the vertical blade 3 is provided with sawtooth 5. The function of the vertical blade 3 is to saw a groove in the pipe fitting 6 in the vertical direction, so as to reduce the cutting of the horizontal cutter 2 behind. resistance to prevent the pipe fitting 6 from sinking and deforming. The horizontal cutter 2 comprises a horizontal blade 7 and a horizontal fixed seat 8, and the horizontal blade 7 and the horizontal fixed seat 8 are also fixed by bolts. The left end of the horizontal blade 7 is a cutting end 9, and the cutting end 9 includes a tip 901. An a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com