Method for brewing foaming saki

A technology of sake and sake yeast, which is applied in the direction of microorganism-based methods, biochemical equipment and methods, and the preparation of alcoholic beverages. The effect of low requirements and high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The brewing of embodiment 1 sparkling sake

[0023] (1) Pulverization of raw materials: commercially available glutinous rice is polished and whitened, and the remaining bran on the rice surface is removed to obtain 100 kg of polished rice, which is then pulverized with a pulverizer and passed through 60 meshes;

[0024] (2) Liquefaction: Mix the obtained glutinous rice flour and water according to the ratio of glutinous rice flour: water = 1:5, and then add malt powder after mixing evenly. The amount of malt powder added is 0.1% of glutinous rice, that is, 0.1kg Malt powder, then use a mixer to stir water, malt powder and glutinous rice flour evenly, add liquefaction enzyme, keep the enzyme activity unit at 20u / g, and spray to liquefy;

[0025] (3) Saccharification: After the liquefaction is completed, filter the liquefied solution with a plate and frame filter to remove the remaining solid residue after liquefaction to obtain a milky white clear liquid. At this time,...

Embodiment 2

[0033] The brewing of embodiment 2 sparkling sake

[0034] (1) Pulverization of raw materials: commercially available glutinous rice is polished to make polished rice, the remaining bran on the surface of the rice is removed to obtain 100 kg of polished rice, and then the polished rice is pulverized with a pulverizer to pass 100 meshes;

[0035] (2) Liquefaction: Mix and stir the obtained glutinous rice flour and water according to the ratio of glutinous rice flour: water = 1:3, and then add malt powder after mixing evenly. , then stir the water, malt powder and glutinous rice flour evenly with a stirrer, add liquefying enzyme, keep the enzyme activity unit at 25u / g, and spray to liquefy;

[0036] (3) Saccharification: After the liquefaction is completed, filter the liquefied solution with a plate and frame filter to remove the remaining solid residue after liquefaction to obtain a milky white clear liquid. At this time, transfer the filtrate to the saccharification pot, adju...

Embodiment 3

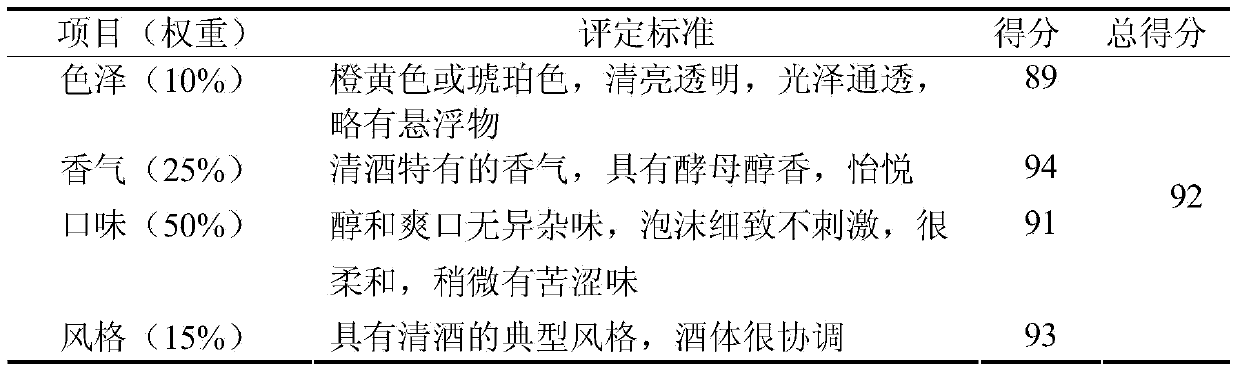

[0042] The detection of embodiment 3 sparkling sake

[0043] (1) Sensory evaluation was carried out on the wine samples obtained in the above-mentioned Example 2 from the four items of color, aroma, taste and style, and the results were as follows:

[0044]

[0045] (2) Physical and chemical index detection of finished sparkling sake:

[0046] Amino acid nitrogen ≥ 0.8g / L, total sugar (calculated as glucose) 30-80g / L,

[0047] Total amino acids ≥ 10mg / mL, non-sugar solids ≥ 15g / L,

[0048] Total acid (calculated as lactic acid)≤5.5g / L, calcium oxide≤0.3g / L,

[0049] Alcohol (20°C) ≥ 3%vol, pH 2.5-3.5,

[0050] Sake yeast content ≥ 150 million / ml

[0051] (3) Foam properties

[0052] The internal pressure of the bottle is ≥0.01MPa; the color of the foam is white, delicate, and creamy, and there is residual foam on the wall of the cup after drinking; the foam lasts for a long time, more than 5 minutes.

[0053] The foamed sake obtained in the present invention also has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com