Method for controlling organic solvent residue in thymosin alpha 1 microspheres

A technology of organic solvents and thymosin, applied in antiviral agents, pharmaceutical formulations, peptide/protein components, etc., can solve problems such as fusion or rupture, adhesion of microspheres, loss of burst release of microsphere preparations, energy efficiency of slow and controlled release, etc., to achieve The effect of maintaining complete shape and process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

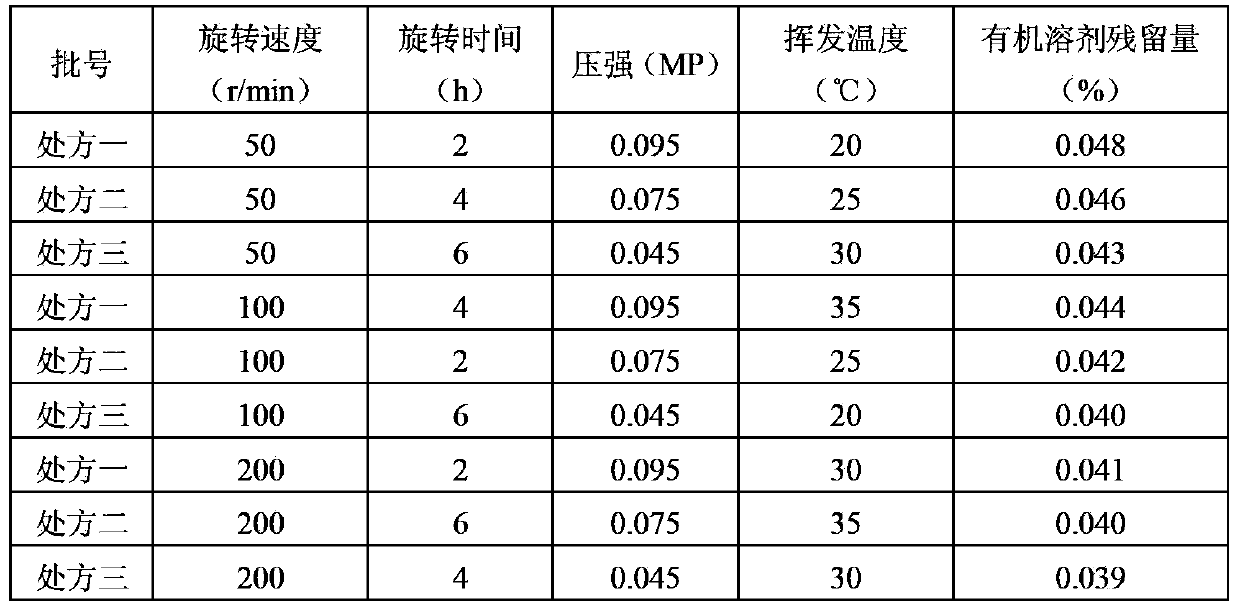

Examples

preparation example Construction

[0039] 1. Preparation of inspection samples

[0040] Prescription 1 (release time 4 weeks)

[0041]Ta1 1.0g

[0042] PLGA (0.15~0.25dl / g) (50 / 50) 36.0g

[0043] Selected organic solvent: dichloromethane

[0044] Preparation process: Add the prescribed amount of Ta1 into 30ml of pH7.4 phosphate buffer at room temperature, dissolve it completely, obtain the aqueous phase, and set aside;

[0045] Add the prescribed amount of PLGA into 150ml of dichloromethane at room temperature to dissolve it completely to obtain an oil phase for subsequent use;

[0046] At 10-25°C, adjust the speed of the emulsifier to 2000-2800 rpm, inject the water phase into the oil phase, and emulsify for 5-10 minutes to obtain colostrum (O / W) for later use;

[0047] Cool 800ml of aqueous solution containing 3%PVA and 5%NaCl to below 10°C, adjust the speed of the mixer to 500-1000 rpm, add colostrum, stir for 2 minutes, then add 3%PVA, 5% NaCl aqueous solution 200ml, get double emulsion (W / O / W), keep i...

Embodiment 1

[0089] Embodiment 1 The present invention controls the method for residual organic solvent in thymosin α1PLGA microspheres

[0090] Ta1 1.0g

[0091] PLGA (0.15~0.25dl / g) (50 / 50) 38.0g

[0092] Preparation Process

[0093] Add the prescribed amount of Ta1 into 30ml of pH7.4 phosphate buffer at room temperature to dissolve completely to obtain an aqueous phase for later use;

[0094] Add the prescribed amount of PLGA into 150ml of dichloromethane at room temperature to dissolve it completely to obtain an oil phase for subsequent use;

[0095]At 10-25°C, adjust the speed of the emulsifier to 2000-2800 rpm, inject the water phase into the oil phase, and emulsify for 5-10 minutes to obtain colostrum (O / W) for later use;

[0096] Cool 800ml of aqueous solution containing 3%PVA and 5%NaCl to below 10°C, adjust the speed of the mixer to 500-1000 rpm, add colostrum, stir for 2 minutes, then add 3%PVA, 5% 200ml of NaCl aqueous solution to obtain double emulsion (O / W / O). Stir for ...

Embodiment 2

[0097] Embodiment 2 The present invention controls the method for residual organic solvent in thymosin α1PLGA microspheres

[0098] Ta1 1.0g

[0099] PLGA (0.24~0.56dl / g) (50 / 50) 32.0g

[0100] Preparation Process

[0101] Add the prescribed amount of Ta1 into 30ml of pH7.4 phosphate buffer at room temperature to dissolve completely to obtain an aqueous phase for later use;

[0102] Add the prescribed amount of PLGA into 100ml of ethyl formate at room temperature to dissolve it completely to obtain an oil phase for later use;

[0103] At 10-25°C, adjust the speed of the emulsifier to 2500-3200 rpm, inject the water phase into the oil phase, and emulsify for 5-10 minutes to obtain colostrum (O / W) for later use;

[0104] Cool 1600ml of aqueous solution containing 2%PVA and 3%NaCl to below 10°C, adjust the speed of the mixer to 500-1000rpm, add colostrum, stir for 2 minutes, then add 2%PVA, 3% 400ml of NaCl aqueous solution to obtain double emulsion (O / W / O). Stir for 3 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com