Vertical double-swing-shaft four-disc-cam four-oscillating-bar knuckle bearing high-speed testing machine

A joint bearing and disc cam technology, applied in the direction of mechanical bearing testing, etc., can solve the problems of dynamic balance of difficult-to-move components, unable to meet the fatigue test of high-frequency swing aviation joint bearing, restricting the development of high-frequency swing aviation joint bearing, etc. Low friction, light wear and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

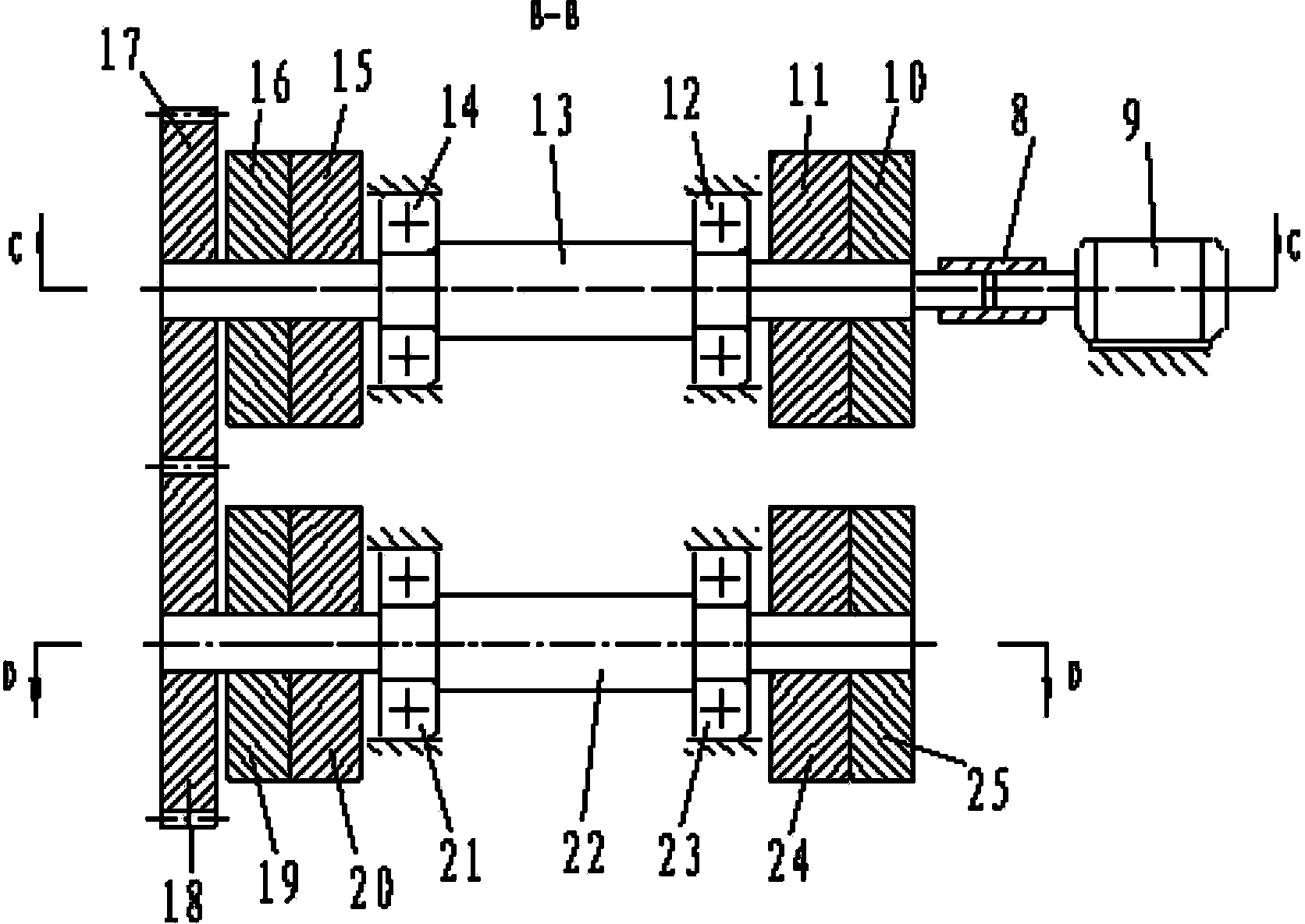

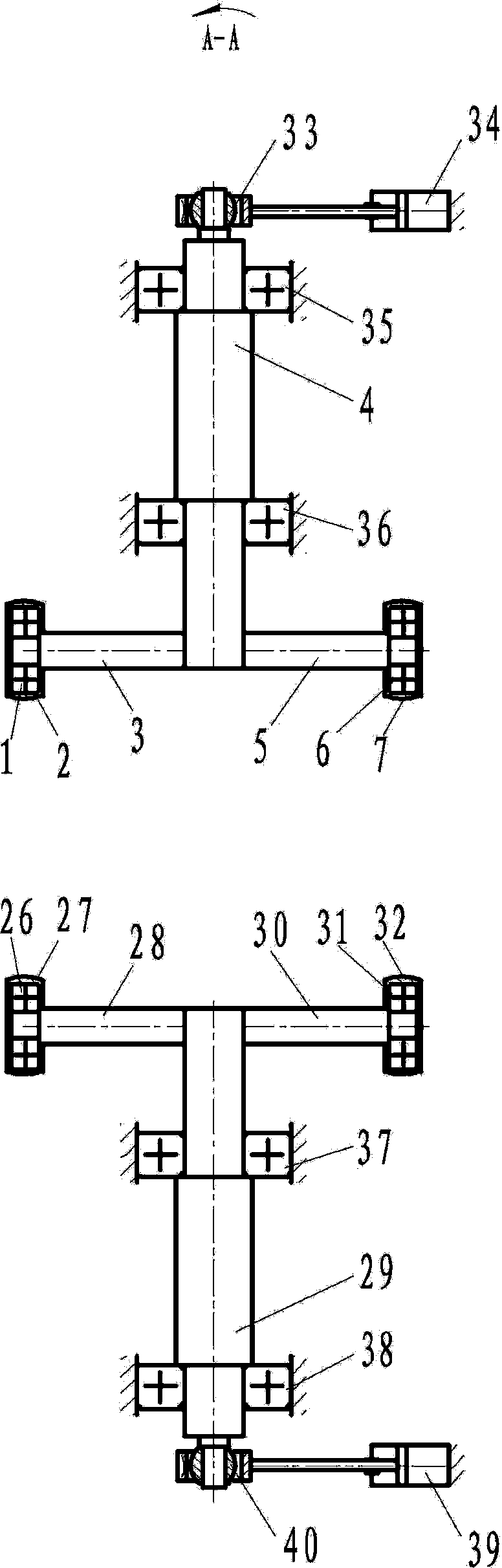

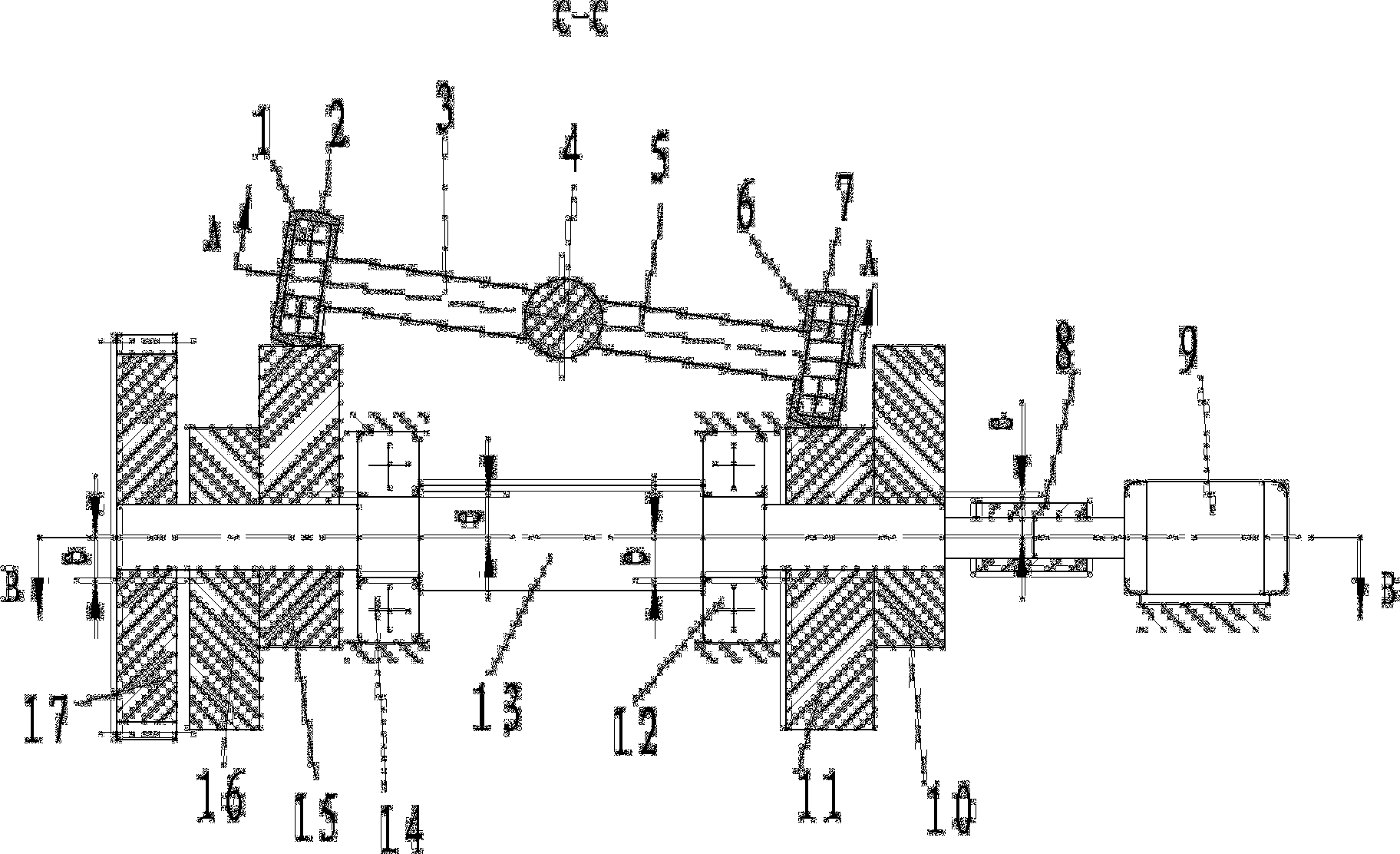

[0018] exist Figure 1 ~ Figure 4 A schematic diagram of the structure of a high-speed testing machine for joint bearings with vertical double pendulum shafts and four disc cams and four pendulum bars is shown. The high-speed rotating shaft I13 is supported on the rolling bearings I and II (12, 14), and the end of the high-speed rotating shaft I13 is fixedly connected to the transmission gear I17; the high-speed rotating shaft II22 is supported on the rolling bearings III and IV (21, 23), and the high-speed rotating shaft The end of II22 is firmly connected with transmission gear II18; two transmission gears I and II (17, 18) are meshed with each other. Between the transmission gear I17 of the high-speed rotating shaft I13 and the rolling bearing II14, the working cam I15 and the balance cam I16 are fixedly installed; on the right side of the rolling bearing I12 of the high-speed rotating shaft I13, the working cam II11 and the balancing cam II10 are fixedly installed; on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com