Electrostatic adsorption type upright cellucotton molding method

A technology of electrostatic adsorption and fiber cotton, applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems of waste of materials, high production costs, and complicated molding steps, and achieve the effect of simple molding steps, low production costs, and short working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

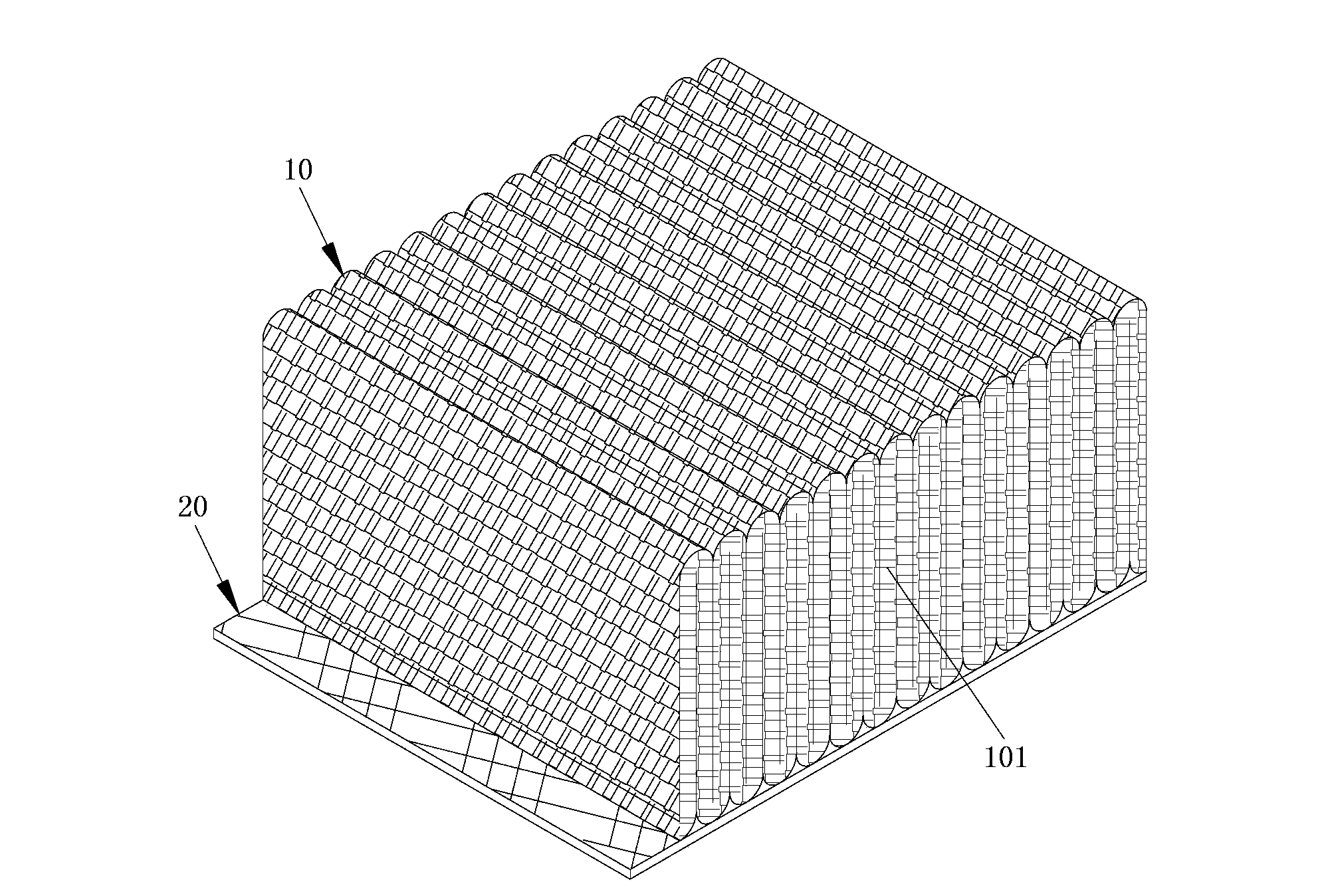

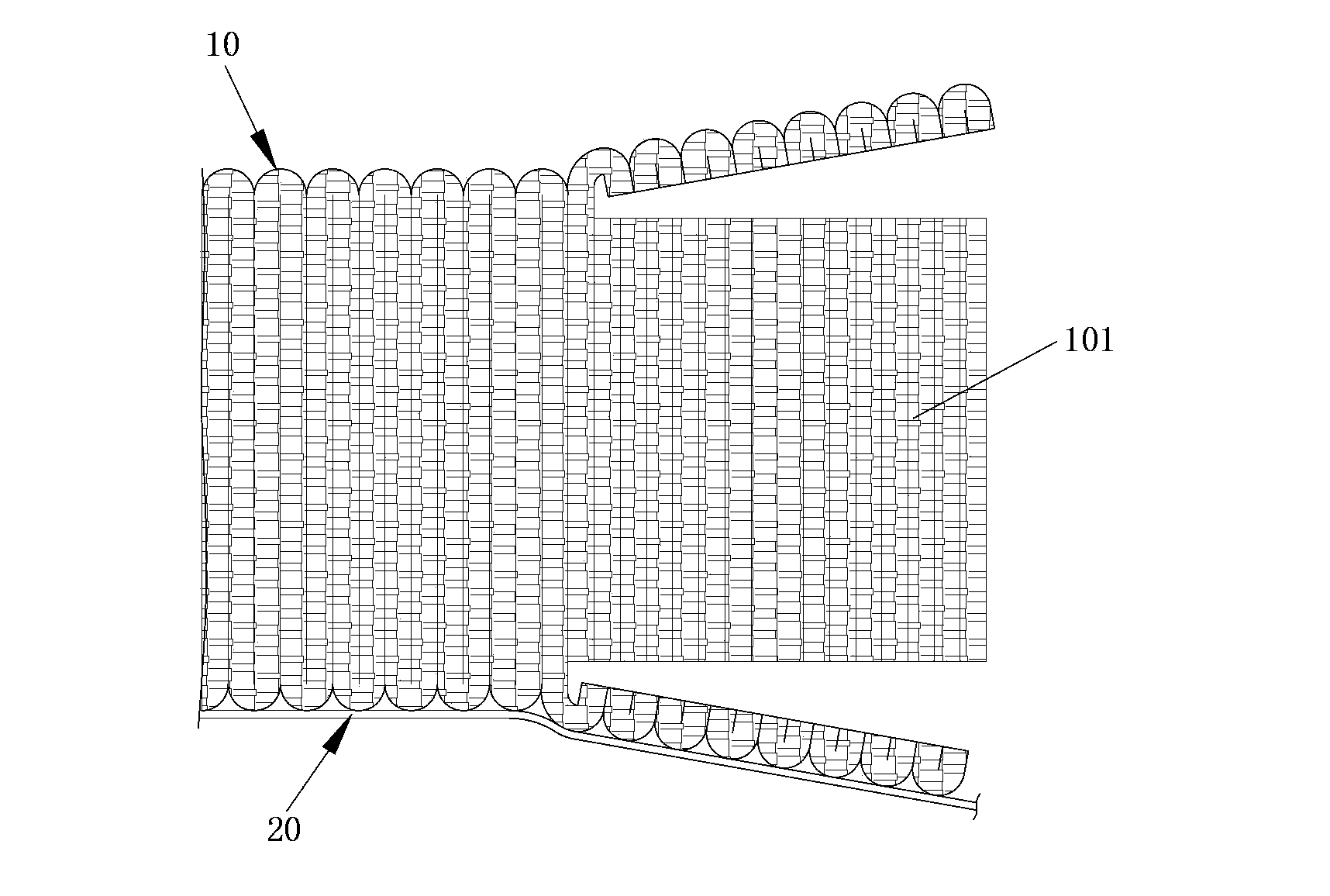

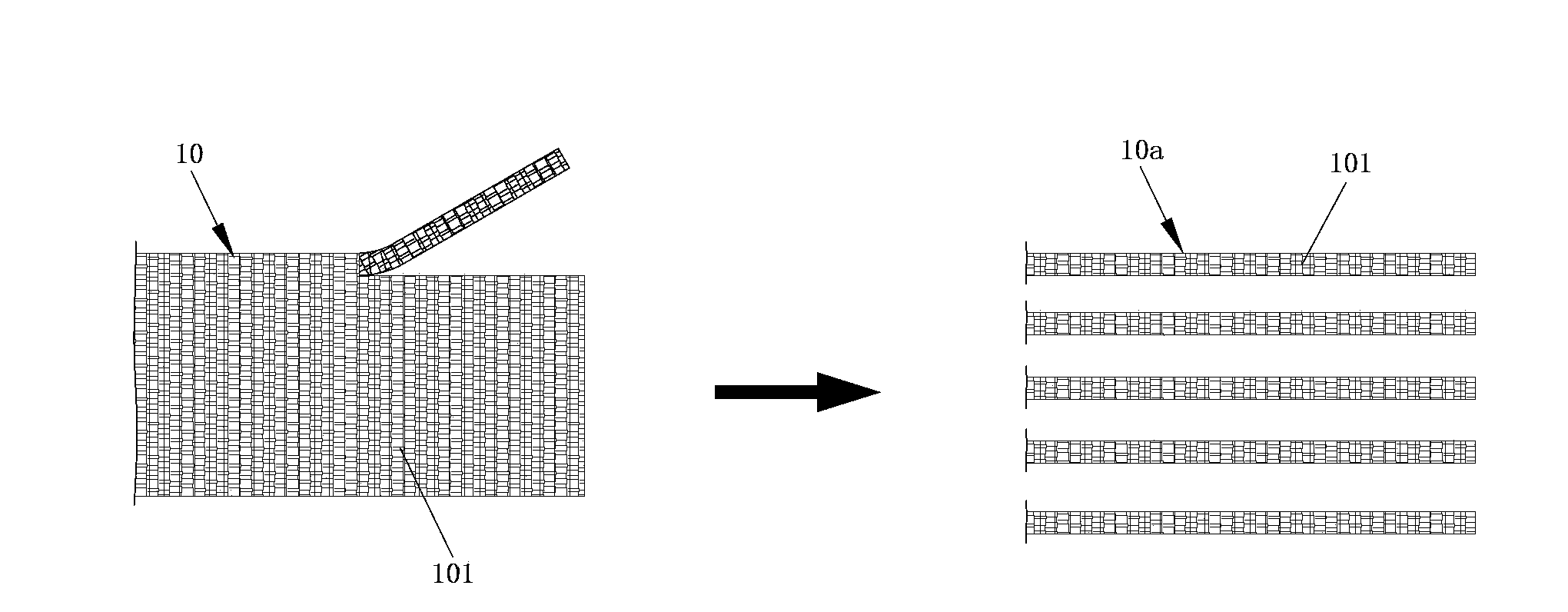

[0029] Preferred embodiments of the present invention will be described in detail below in conjunction with accompanying drawings:

[0030] Such as Figure 4 , Figure 5 , Figure 6 and Figure 7 Shown, electrostatic adsorption type upright fiber cotton molding method of the present invention comprises the following steps:

[0031] a. Electrostatic stretching, after opening a predetermined number of staple fibers 11, place them in the electrostatic space C formed between the upper and lower electrostatic plates A and B, and pass through the upper and lower electrostatic plates A and B in the electrostatic space Static electricity is generated in C, and the staple fiber 1 is stretched between the upper and lower electrostatic plates A and B to form an upright shape by the principle of static electricity;

[0032] b. Heating and bonding, put the stretched short filament fiber 11 into an upright shape together with the upper and lower electrostatic plates A, B into the oven, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com