Yellowing resistant liquid optical adhesive

An optical adhesive, anti-yellowing technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc. Excellent yellowing and aging resistance, improving uniformity and promoting uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

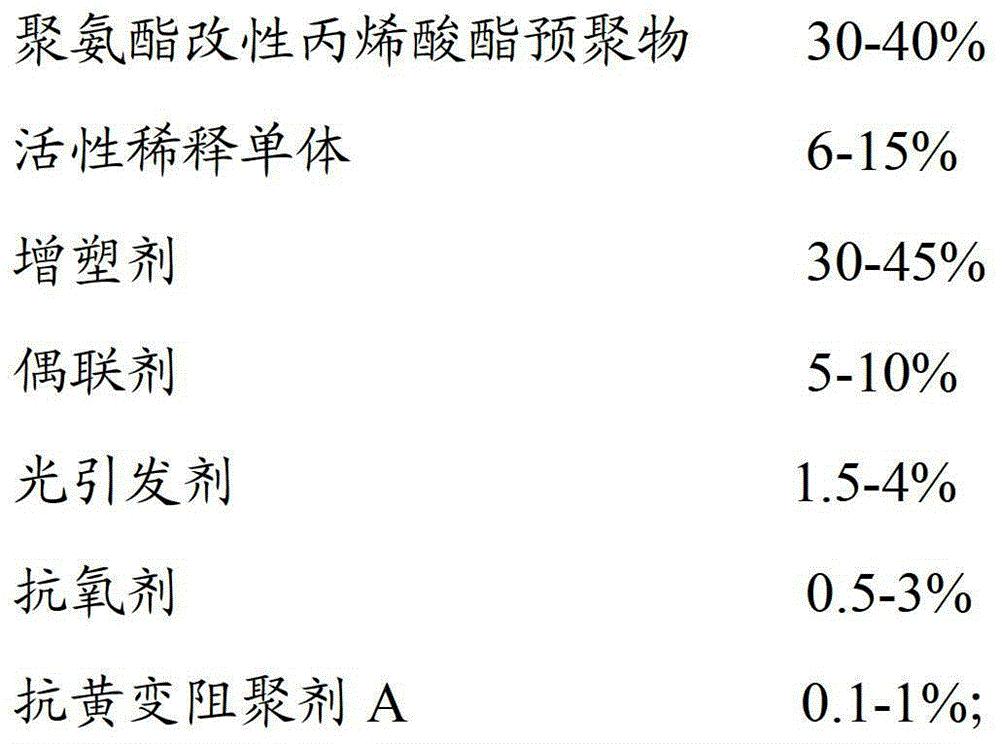

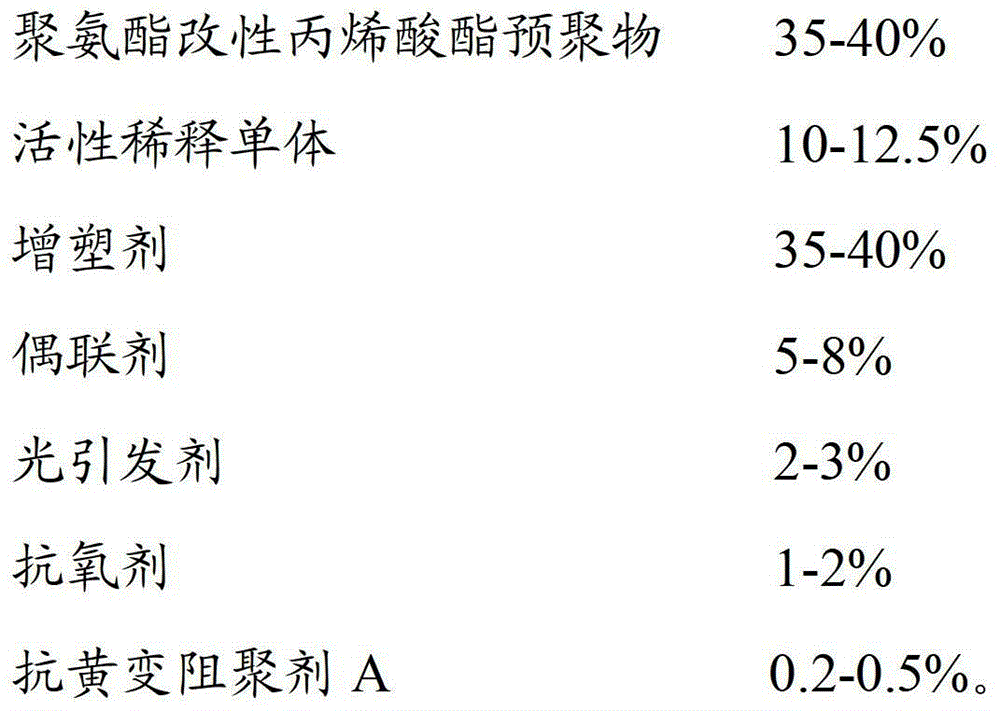

Method used

Image

Examples

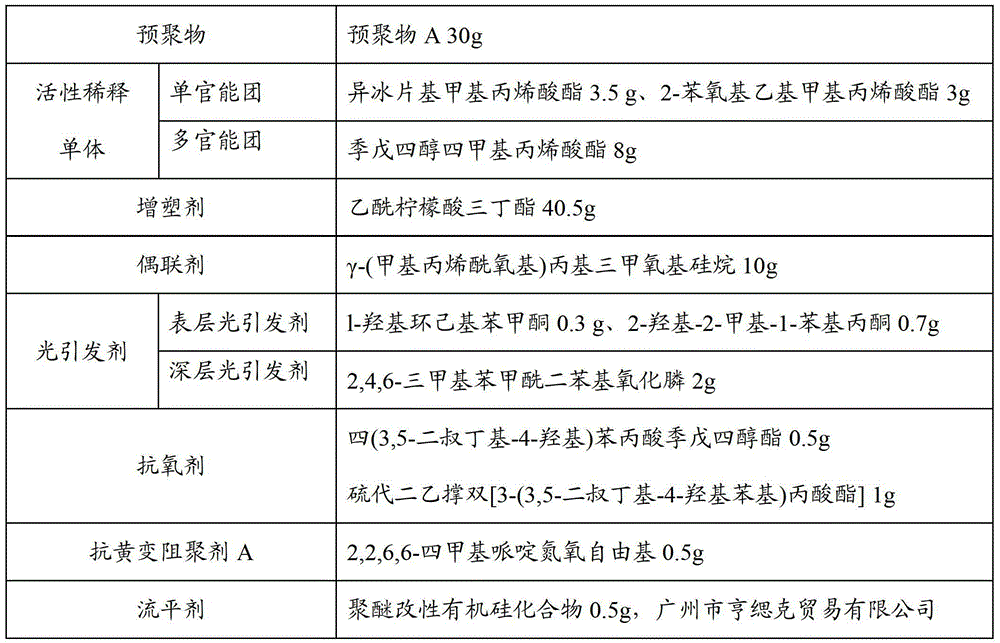

Embodiment 1

[0039] Prepare polyurethane-modified acrylate prepolymer, which is denoted as prepolymer A, and the preparation method is as follows:

[0040] Add 113g of polypropylene glycol (PPG-2000, Jiangsu Haian Petrochemical Plant) and 87g of polycaprolactone diol (molecular weight 2000, Daicel, Japan) into a flask equipped with a thermometer, an air inlet and a stirring device, and heat to 100 ℃, vacuum dehydration for 2 hours, the moisture content was determined to be less than 0.05% by Karl Fischer method, 0.2g catalyst dibutyltin dilaurate was added, the temperature was raised to 115℃, 23.8g isophorone diisocyanate and 16.5g dibutyltin dilaurate were added dropwise Cyclohexylmethane diisocyanate (HMDI), stirred for 5 hours, then added 18.9g of hydroxypropyl acrylate and 0.1g of catalyst dibutyltin dilaurate, 0.2g of 2,2,6,6-tetramethylpiperidine nitroxide , continued the reaction at 90°C for 8 hours, after the reaction was completed, the stretching vibration peak of the isocyanate g...

Embodiment 2

[0046] Prepare polyurethane modified acrylate prepolymer, denoted as prepolymer B, preparation method comprises the following steps:

[0047] Add 129g of polytetrahydrofuran diol (PTMEG-2000, molecular weight of 2000, BASF) and 107g of polycaprolactone diol (molecular weight of 3000, Japan Daicel) into a flask equipped with a thermometer, an air inlet and a stirring device, and heat to 100°C, vacuum dehydrate for 2.5h, use the Karl Fischer method to measure the moisture content below 0.05%, add 0.095g catalyst dibutyltin dilaurate, raise the temperature to 100°C, add dropwise 27g isophorone diisocyanate and 14g Dicyclohexylmethane diisocyanate (HMDI), stirred for 4 hours, then added 27.6g o-hydroxycyclohexyl methacrylate and 0.35g catalyst dibutyltin dilaurate, 0.12g2,2,6,6-tetramethyl Piperidine nitroxide free radicals, continue to react at 80°C for 6h, the reaction is completed, and the isocyanate group is measured by infrared spectroscopy at 2270cm -1 The stretching vibrat...

Embodiment 3

[0053] Prepare polyurethane modified acrylate prepolymer, denoted as prepolymer C, preparation method comprises the following steps:

[0054] Add 180g of polypropylene glycol (PPG-3000, Jiangsu Haian Petrochemical Plant) and 80g of polycaprolactone diol (molecular weight 2000, Daicel, Japan) into a flask equipped with a thermometer, an air inlet and a stirring device, and heat to 90 ℃, vacuum dehydration for 1h, the moisture content was determined to be below 0.05% by Karl Fischer method, 0.39g of catalyst dibutyltin dilaurate was added, the temperature was raised to 90°C, 26g of isophorone diisocyanate and 12.4g of bicyclic Hexylmethane diisocyanate (HMDI), stirred for 6 hours, then added 20.2g of 2-hydroxyethyl methacrylate and 0.39g of catalyst dibutyltin dilaurate, 0.26g of 2,2,6,6-tetramethylpiperidine nitrogen oxide Free radicals continued to react at 90°C for 7 hours. After the reaction was completed, the stretching vibration peak of the isocyanate group at 2270cm-1 was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com