Preparation method of dark-blue zirconia ceramic

A technology of zirconia ceramics and dark blue, which is applied in the field of preparation of dark blue zirconia ceramics, which can solve the problems of poor high-temperature stability of pigments, rising production costs, and high requirements for sintering furnaces, achieving low cost, reducing costs, and ensuring mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

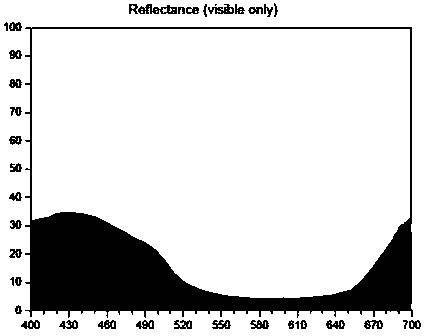

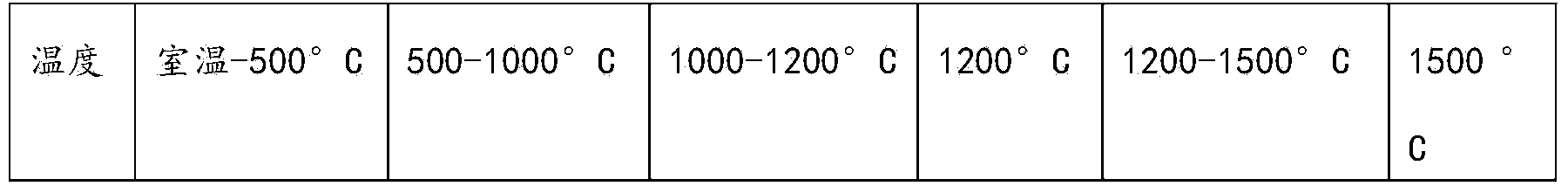

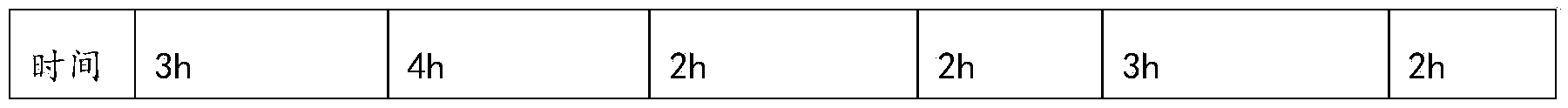

[0028] Weigh 30 grams of polyvinyl butyral and dissolve it in 5000 grams of absolute alcohol, pour it into a 5L ball mill bottle after fully dissolving, add 1000 grams of yttrium oxide stabilized zirconia powder with a mole fraction of 3% (purity is 99%, average particle diameter 0.5 μm), weighed 20 grams of cobalt aluminate and 10 grams of cobalt oxide into the ball milling bottle at the same time, both cobalt aluminate and cobalt oxide were analytically pure, and 10 grams of polyethyleneimine was used as a dispersant. After ball milling for 24 hours, the suspended The turbid liquid was poured out, and after drying to remove the alcohol, the ceramic powder was ground and passed through a 500-mesh sieve, and then isostatically pressed to prepare a zirconia rod with a diameter of 20 mm and a length of 100 mm. After slow debinding, it is put into a high-temperature sintering furnace and sintered into products. The temperature rise curve during sintering is:

[0029]

[0030]...

Embodiment 2

[0033] Weigh 35 grams of polyvinyl butyral and dissolve it in 5500 grams of absolute alcohol, pour it into a 5L ball mill bottle after fully dissolving, add 1100 grams of yttrium oxide stabilized zirconia powder with a mole fraction of 4% (purity is 99%, average particle diameter 0.8μm), weighed 22 grams of cobalt aluminate and 12 grams of cobalt oxide and added them to the ball mill bottle at the same time. Both cobalt aluminate and cobalt oxide were of analytical grade, and 11 grams of polyethyleneimine was used as a dispersant. After ball milling for 24 hours, the suspended The turbid liquid was poured out, and after drying to remove the alcohol, the ceramic powder was ground and passed through a 500-mesh sieve, and then isostatically pressed to prepare a zirconia rod with a diameter of 20 mm and a length of 100 mm. After slow debinding, it is put into a high-temperature sintering furnace and sintered into finished products. The temperature rise curve during sintering is: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com