Preparation method and application of gemini amphiphilic surfactant

A surfactant and amphiphilic technology, applied in the direction of sulfonate preparation, drilling compositions, chemical instruments and methods, etc., can solve the problems of large adsorption loss, achieve reduced interfacial tension, stable performance, and temperature resistance The effect of low performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

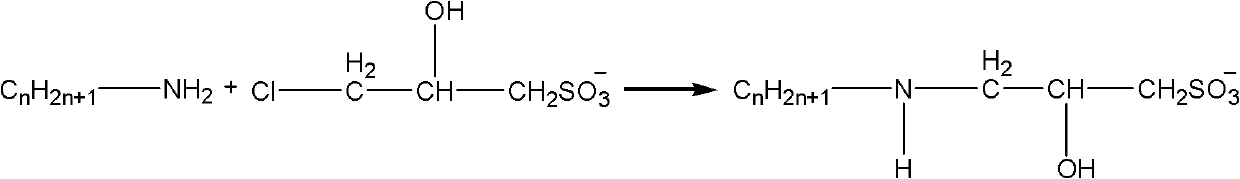

[0021] Add 27g of octadecylamine and 25g of 3-chloro-2-hydroxypropanesulfonate into 100g of isopropanol containing 0.5g of tetrabutylammonium bromide, heat to reflux, and react for 10 hours, then add 5g of sodium hydroxide, Adjust the pH to 8-9, then add 4 g of 1,2-dichloroethane, and heat to reflux for 24 hours. Stop heating, let stand, spend the night, and the reaction solution is removed solvent by decompression distillation, obtains C 18 Alkyl gemini amphiphilic surfactants are washed and recrystallized to obtain pure products with a measured yield of 66%.

[0022] Get the gemini amphiphilic surfactant 35g that above-mentioned method prepares, secondary alkyl sodium sulfonate 25g, sorbitan monooleate 15g, water 20g, fully stir, obtain effective content and be 80% oil displacement surfactant system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com