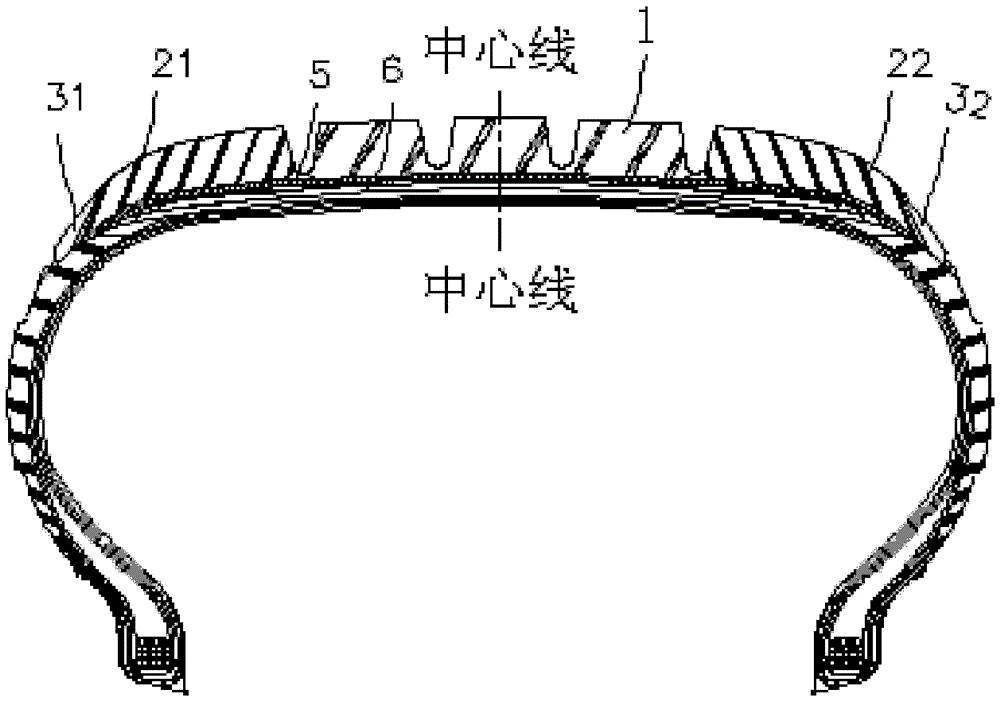

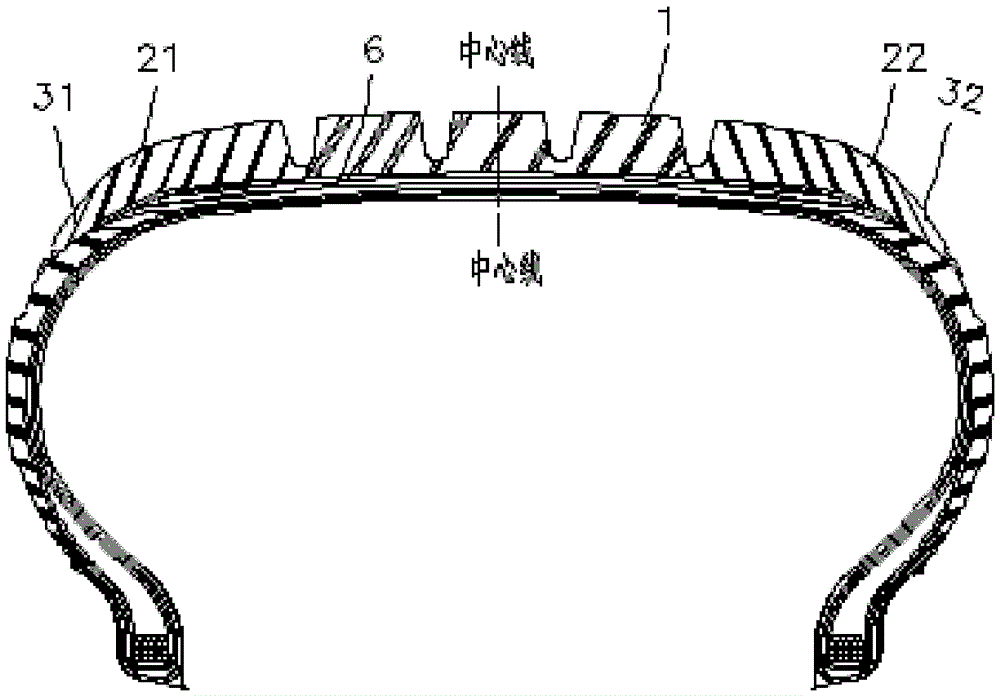

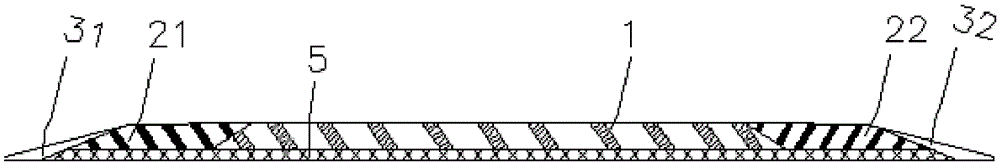

low rolling resistance tire

A low rolling resistance, tire technology, applied in the direction of rolling resistance optimization, special tires, tire parts, etc., can solve the problems of poor wear performance, serious wear of the shoulder part, uneven wear and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] 350g of styrene-butadiene rubber produced by JSR company with the brand name of SBR1502, 150g of butadiene rubber with the brand name of BR9000 produced by Shanghai Gaoqiao Company, 175g of carbon black produced by Shanghai Cabot Company with the brand name of N234, and 250g of the brand produced by UnitedSilica Company is 7000GR White carbon black, 20g bis-(3-triethoxysilylpropyl)-tetrasulfide produced by DEGUSSA company, 100g process oil produced by H&RGROUP company with the brand name VIVATEC500, 10g stearic acid, 10g synthetic wax, 10g zinc oxide Powder and 10g of 6PPD anti-aging agent produced by Taian Sennics Chemical Co., Ltd. were pre-mixed in a mechanical container at high speed for 30s, then mixed at medium speed for 3min, and finally discharged at 145°C and cooled. Leave it for 4h. Then the obtained mixture was mixed with 4g of DPG accelerator produced by Shandong Shangshun Chemical Co., Ltd., 9g of CBS accelerator produced by Zhenjiang Zhenbang Company and 9...

Embodiment 2

[0102]250g of styrene-butadiene rubber produced by JSR company with the brand name of SBR1502, 206g of styrene-butadiene rubber produced by JSR company with the brand name of HP755, 100g of butadiene rubber produced by Shanghai Gaoqiao Company with the brand name of BR9000, and 50g of the brand produced by Shanghai Cabot Company are Carbon black of N234, 450g of white carbon black with the brand name of 7000GR produced by UnitedSilica company, 36g of process oil containing bis-(3-triethoxysilanepropyl)-tetrasulfide produced by DEGUSSA company, 44g of process oil produced by H&RGROUP company with the brand name of VIVATEC500 , 10g of stearic acid, 10g of synthetic wax, 10g of zinc oxide powder and 10g of 6PPD anti-aging agent produced by Taian Sennics Chemical Co., Ltd. were pre-mixed at high speed for 30s in a mechanical container, and then the obtained mixture was mixed at a medium speed After mixing for 3 minutes, unload at 155°C, cool and place for 4 hours. Then the obtaine...

Embodiment 3

[0108] 200g of styrene-butadiene rubber produced by JSR company with the brand name of SBR1502, 275g of styrene-butadiene rubber produced by JSR company with the brand name of HP755, 100g of butadiene rubber produced by Shanghai Gaoqiao Company with the brand name of BR9000, and 200g of the brand produced by Shanghai Cabot Company are The carbon black of N234, 250gUnitedSilica's brand production is the white carbon black of 7000GR, the two-(3-triethoxysilyl propyl group)-tetrasulfide produced by 20gDEGUSSA company, the process oil of VIVATEC500 produced by 25gH&RGROUP company's brand, 10g of stearic acid, 10g of synthetic wax, 10g of zinc oxide powder and 10g of 6PPD anti-aging agent produced by Taian Sennics Chemical Co., Ltd. were pre-mixed at high speed for 30 seconds in a mechanical container, and then the obtained mixture was mixed at a medium speed. After mixing for 3 minutes, unload at 145°C, cool, and place for 4 hours. Then mix the obtained mixture with 4g of DPG anti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com