Method for treating oil refining wastewater

A technology for oil refinery wastewater and treatment pools, applied in the field of water treatment, can solve the problems of no removal effect and low ammonia nitrogen removal efficiency, and achieve the effects of saving investment, avoiding inhibition and lethal effects, and saving investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

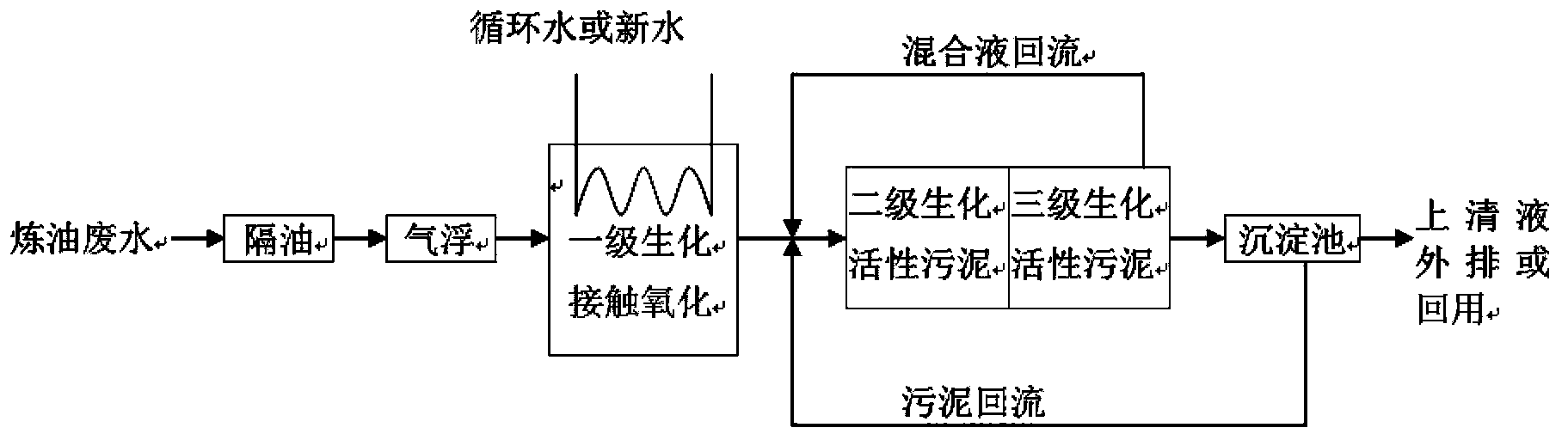

Embodiment 1

[0026]For the refinery wastewater of an oil refinery, oil separation and air flotation are used for pretreatment. The pretreated water temperature is 25-40°C, COD400-1500mg / L, and ammonia nitrogen 35-120mg / L. Then adopt the steps and methods mentioned in the summary of the invention in sequence, that is, the process of primary biochemical (contact oxidation), secondary biochemical (activated sludge), tertiary biochemical (activated sludge) and sedimentation process. Both the mixed solution of the third-stage biochemical tank and the sludge of the sedimentation tank are returned to the second-stage biochemical tank, and the reflux ratio is 150% and 50% respectively. The first-level biochemical pool is filled with suspended packing, a heat exchanger is installed, and the water temperature is adjusted to about 30°C with fresh water; the third-level biochemical pool is installed with combined packing. Blast aeration makes the dissolved oxygen in the first biochemical pool, the fro...

Embodiment 2

[0028] The volume of refinery wastewater in an oil refinery is about 50m 3 / h, after oil separation-air flotation pretreatment, the average COD and ammonia nitrogen of the effluent are about 800mg / L and 70mg / L, and the water temperature is 30-45°C. The effluent treated by the original treatment device of the plant far exceeds the discharge standard and has no removal effect on ammonia nitrogen. After the technical transformation of the original treatment device by the method of the present invention, the waste water can be discharged up to the standard without adding new structures.

[0029] The original treatment device adopts the process of "oil separation, air flotation, primary biochemical (contact oxidation), secondary biochemical (contact oxidation), tertiary biochemical (contact oxidation), and precipitation". The hydraulic retention time of each biological treatment tank is 11.7h, and elastic fillers are installed in the tanks, and the sludge from the sedimentation tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com