Method and device for treating catering wastewater

A technology for catering wastewater and treatment device, applied in the field of environmental engineering, can solve problems such as poor treatment effect, high oil content, difficult management, etc., and achieve the effects of stable and reliable effluent water quality, high sludge load and low operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

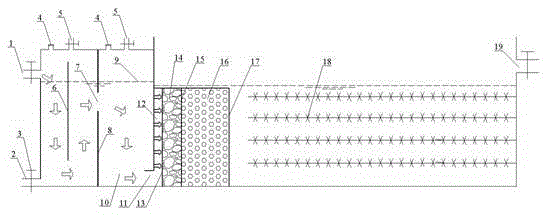

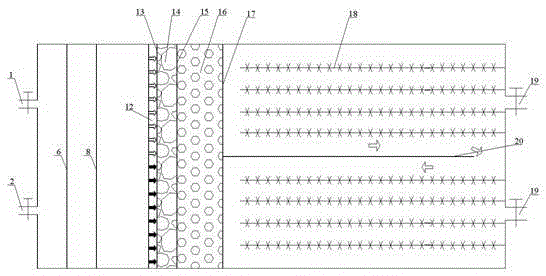

[0020] Implementation process: The catering wastewater of a certain canteen is used as the influent water source, the flow rate is 6 tons / d, and the sewage enters the alternate flow integrated catering wastewater treatment device after passing through the grille. COD (chemical oxygen demand), BOD (biochemical oxygen demand), SS (solid suspended solids concentration), NH3-N (ammonia nitrogen) in raw water are: 1500~2000mg / L, 850~1200mg / L, 600~900mg / L, 15~20mg / L.

[0021] The overall length, width and height of the equipment are 4500mm, 2000mm and 2500mm respectively, the thickness of the sand filter layer is 300mm, the thickness of the ceramsite layer is 600mm, the particle size of ceramsite is 3~5mm, and the length of the alternating flow reactor is 3500mm. The hydraulic retention time (HRT) is 8h.

[0022] Dissolved oxygen (DO) control: the DO in the front section of the fully mixed reaction zone is 4.0-6.5mg / L, and the DO in the end section of the plug-flow reaction zone i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com