CMP (Chemical mechanical polishing) simulation method

A simulation method and chemical-mechanical technology, applied in the field of chemical-mechanical polishing simulation, can solve problems such as affecting the accuracy of CMP simulation, worsening prediction effect, and reducing simulation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

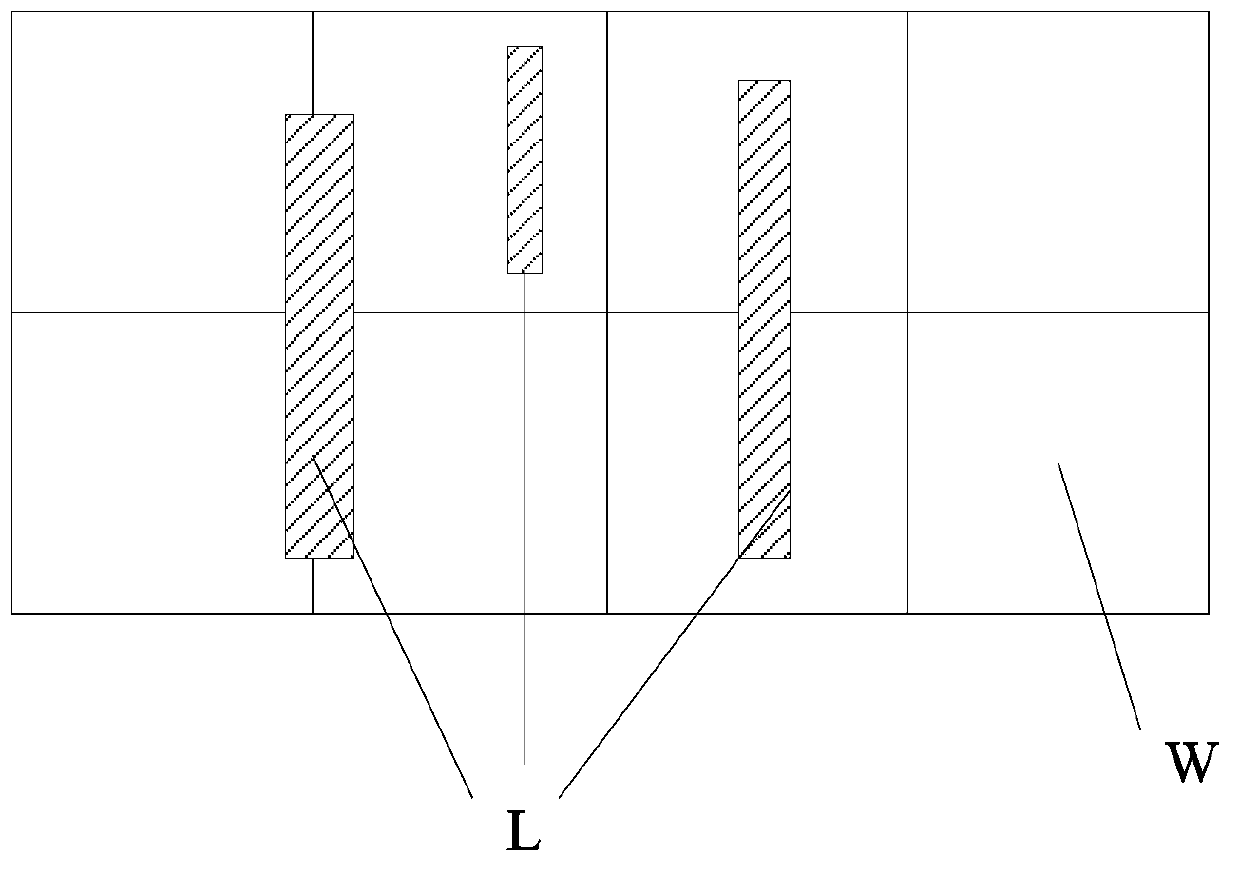

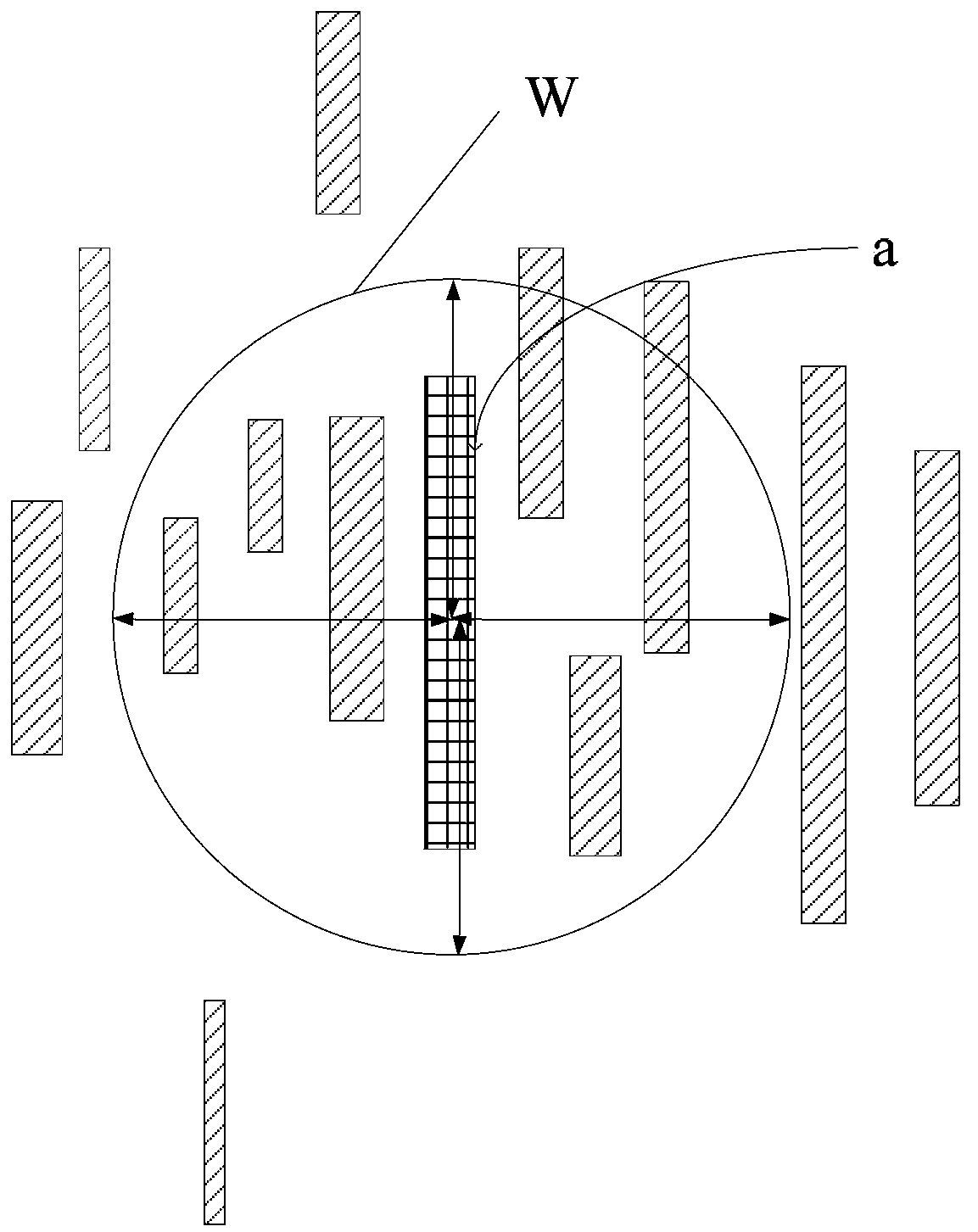

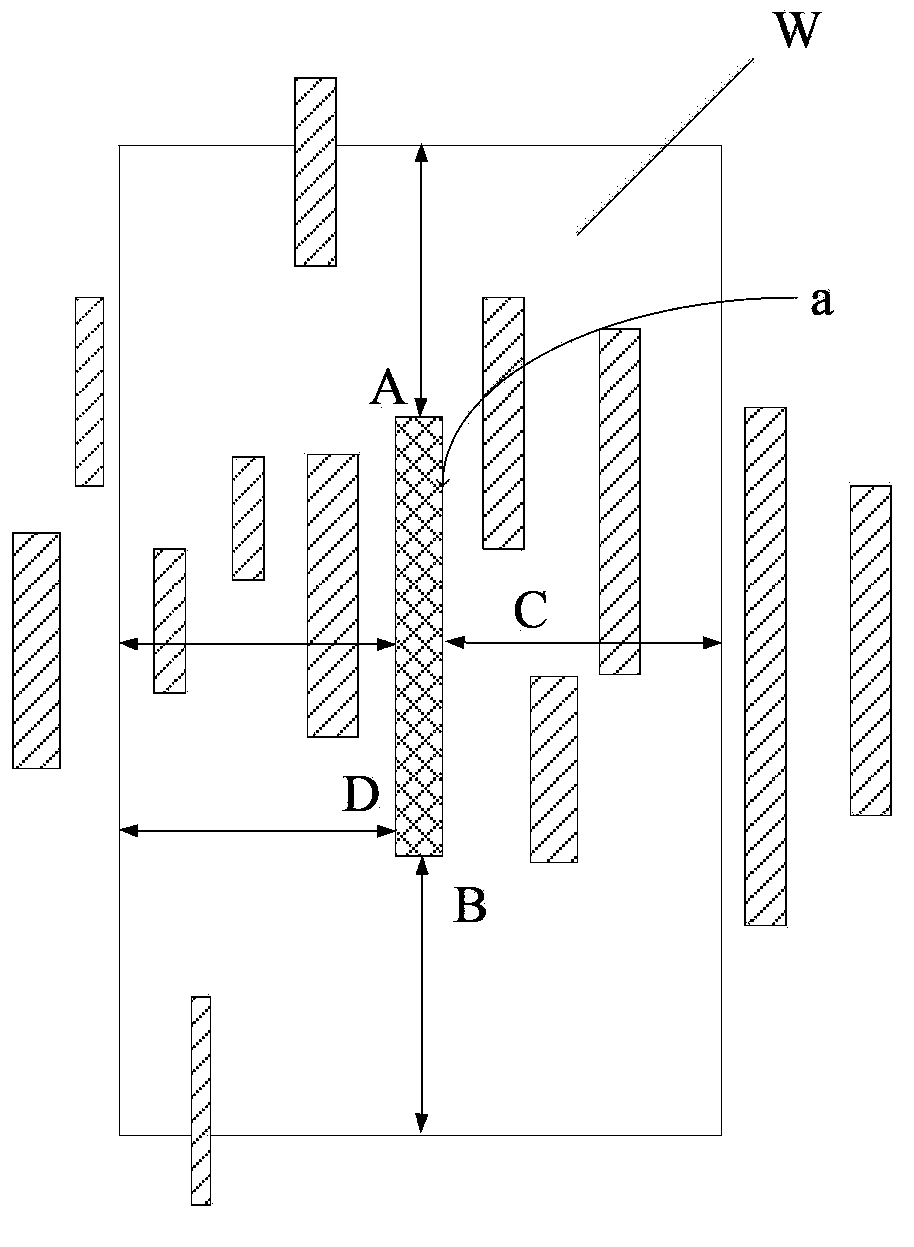

[0054] In the CMP simulation process, layout division is a very important step. All subsequent simulation processes are based on the divided panes. Different division methods lead to different CMP simulation results. The existing layout division method is a fixed division method, which will reduce the simulation accuracy and deteriorate the prediction effect. The present invention provides a partitioning method adapted to different interconnecting line structures in the layout, that is, a method for dividing panes according to the distribution of interconnecting lines in the layout.

[0055] In order to make the above objects, features and beneficial effects of the present invention clearer, the specific implementation of the chemical mechanical polishing simulation method of the present invention will be described in detail below with reference to the accompanying drawings.

[0056] In the following description, a lot of specific details are set forth in order to fully unders...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com