Heat pipe

A heat pipe and pipe body technology is applied in the field of heat pipes with a braided capillary structure, which can solve problems such as general working fluid efficiency, and achieve the effects of improving heat conduction efficiency, reducing backflow resistance, and improving heat pipe performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

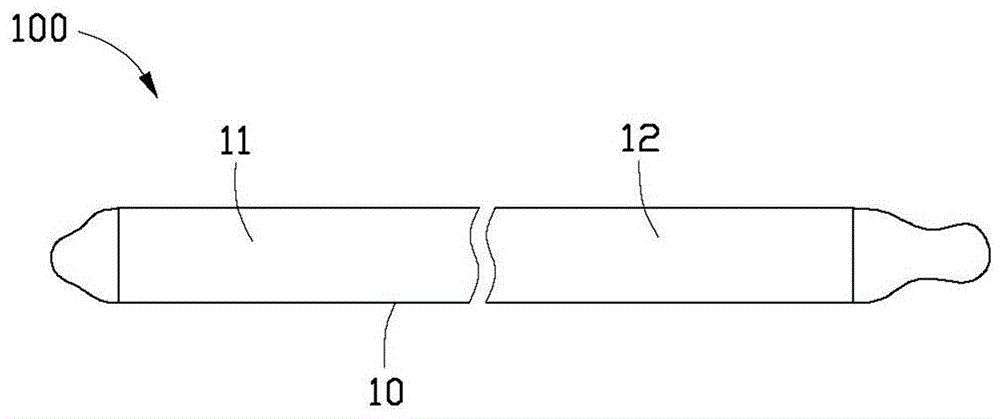

[0031] see Figure 1 to Figure 3 , the heat pipe 100 includes a flat tube body 10, a capillary structure 20 disposed in the tube body 10 and an appropriate amount of working fluid 30 injected into the tube body 10 (see Figure 7 ). The heat pipe 100 includes an evaporation section 11 and a condensation section 12 along the axial direction. In this embodiment, the heat pipe 100 is a thin heat pipe.

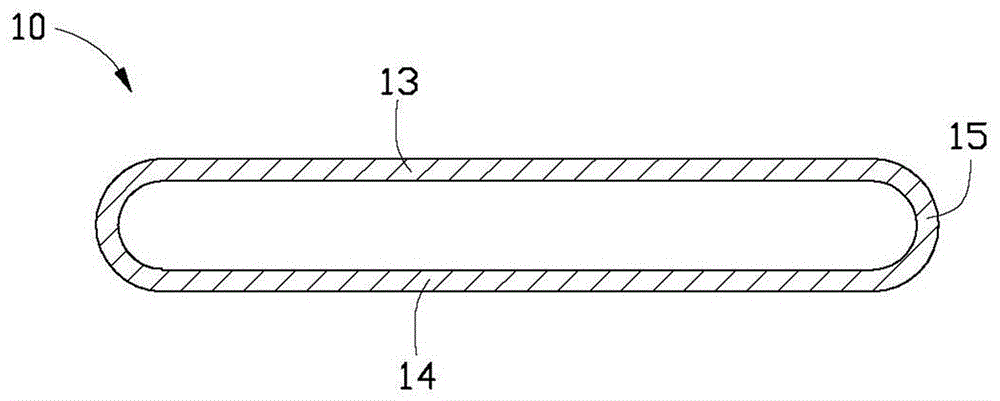

[0032] The pipe body 10 is made of copper and other materials with good thermal conductivity. The tube body 10 is hollow, elongated and flat, and is formed by flattening a circular tube. The thickness of the pipe wall of the pipe body 10 is less than 1.5mm. The tube body 10 includes a top plate 13 , a bottom plate 14 and two side plates 15 . The top plate 13 and the bottom plate 14 are parallel to each other and symmetrical up and down. The two side plates 15 are arc-shaped, respectively located on two sides of the pipe body 10 and connect the top plate 13 and the bottom plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com