Household multifunctional computer sewing machine

A sewing machine and multi-functional technology, which is applied in the direction of sewing machine components, sewing machine needle holders, program-controlled sewing machines, etc., can solve the problems of increased production cost of sewing machines, poor use safety, high power consumption, etc., and achieve coordinated appearance, beauty and convenience Effect of winding and reducing material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing:

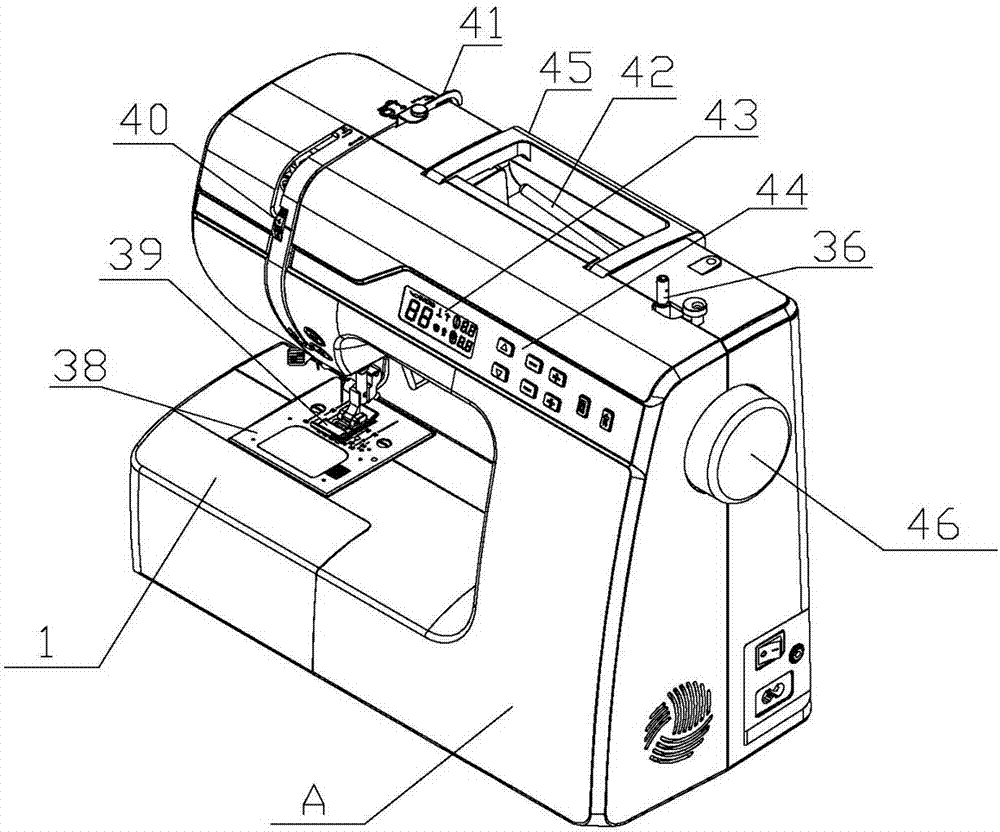

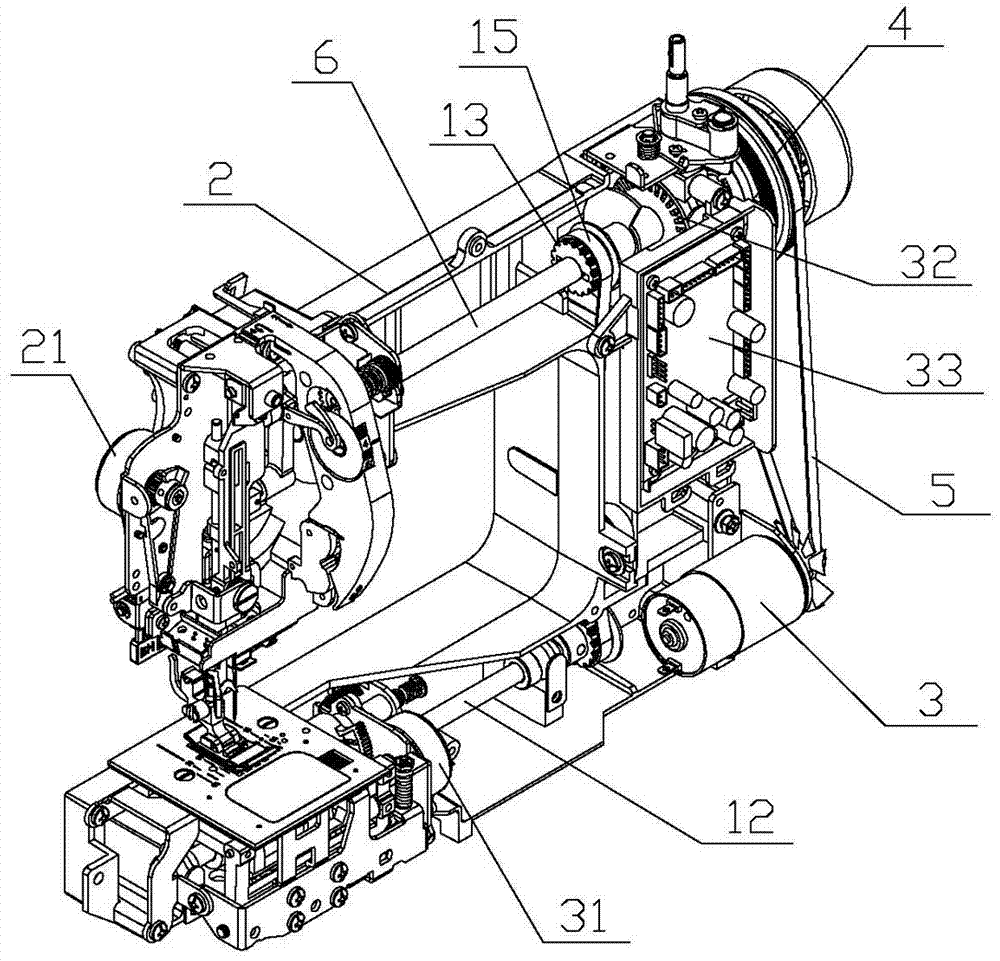

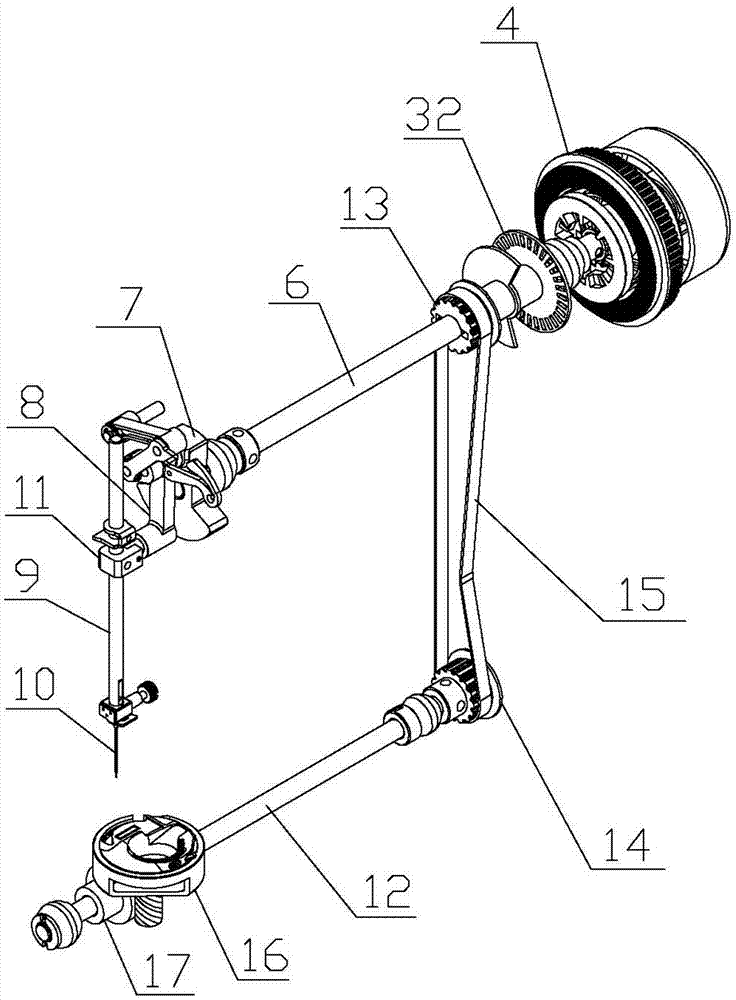

[0036] With reference to the accompanying drawings, this household multifunctional computer sewing machine comprises a sewing machine casing A, the surface of the sewing machine casing A is provided with a detachable workbench 1, and the sewing machine casing A is provided with a built-in casing 2, and the built-in casing 2 is provided with a main motor 3, the output end of the main motor 3 is connected with a pulley 4 installed on the built-in casing 2, the main motor 3 is connected with the pulley 4 through the motor belt 5, the pulley 4 is connected with a main shaft 6, and the main shaft 6 The output end of the shaft is connected with the main shaft balance cam 7, the main shaft balance cam 7 is provided with a small connecting rod 8, the output end of the small connecting rod 8 is connected with the needle bar 9, the output end of the needle bar 9 is provided with a mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com