Aluminium alloy plate with excellent laser welding performance and preparation method thereof

A technology of laser welding and aluminum alloy plate, which is applied in the field of aluminum alloy processing, can solve the problems of poor weld pool uniformity, affecting the safety performance of the shell sealing battery, and high quality defect rate, so as to prevent abnormal weld pool and excellent laser Welding performance, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

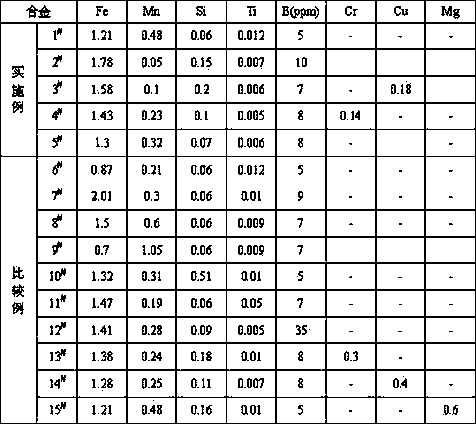

[0034]The alloy given in Table 1 was melted and cast, and the alloy ingot was heated from room temperature to 600°C at a heating rate of 50°C / h and kept at a temperature of 2h, then cooled at a rate of 50°C / h to 500°C and kept at a temperature of 2h, and then hot-rolled; Then cold-roll the hot-rolled sheet to a thickness of 1.0mm, raise the temperature of the cold-rolled sheet to 380°C at a rate of 30°C / h and keep it warm for 1 hour, then air-cool to finally obtain the required sheet.

[0035] Table 1

[0036]

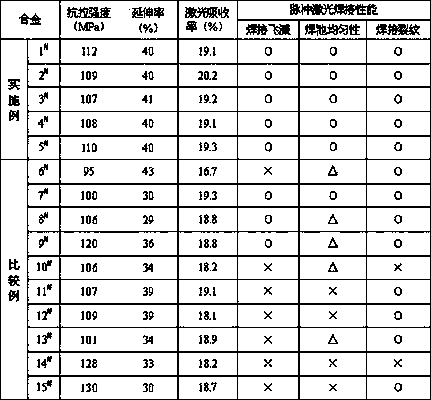

[0037] Table 2 shows the evaluation results of tensile strength, elongation and pulse laser welding performance of each alloy sheet in Table 1.

[0038] Table 2

[0039]

[0040] Remarks: 1) The pulse laser welding performance is evaluated when the weld pool penetration is within 0.4~0.6mm;

[0041] 2) Observing the surface of the weld pool through an optical microscope, the weld pool without spatter is "O", and the spatter is "×";

[0042] 3) Observing the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com