Method for refining dihydroquercetin from larch

A technology of dihydroquercetin and larch, applied in the direction of organic chemistry, can solve the problems of inconvenient continuous production of adsorbents, large solvent consumption, increased crystallization times, etc., and achieve high yield, low self-residue, The effect of simplifying the production steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

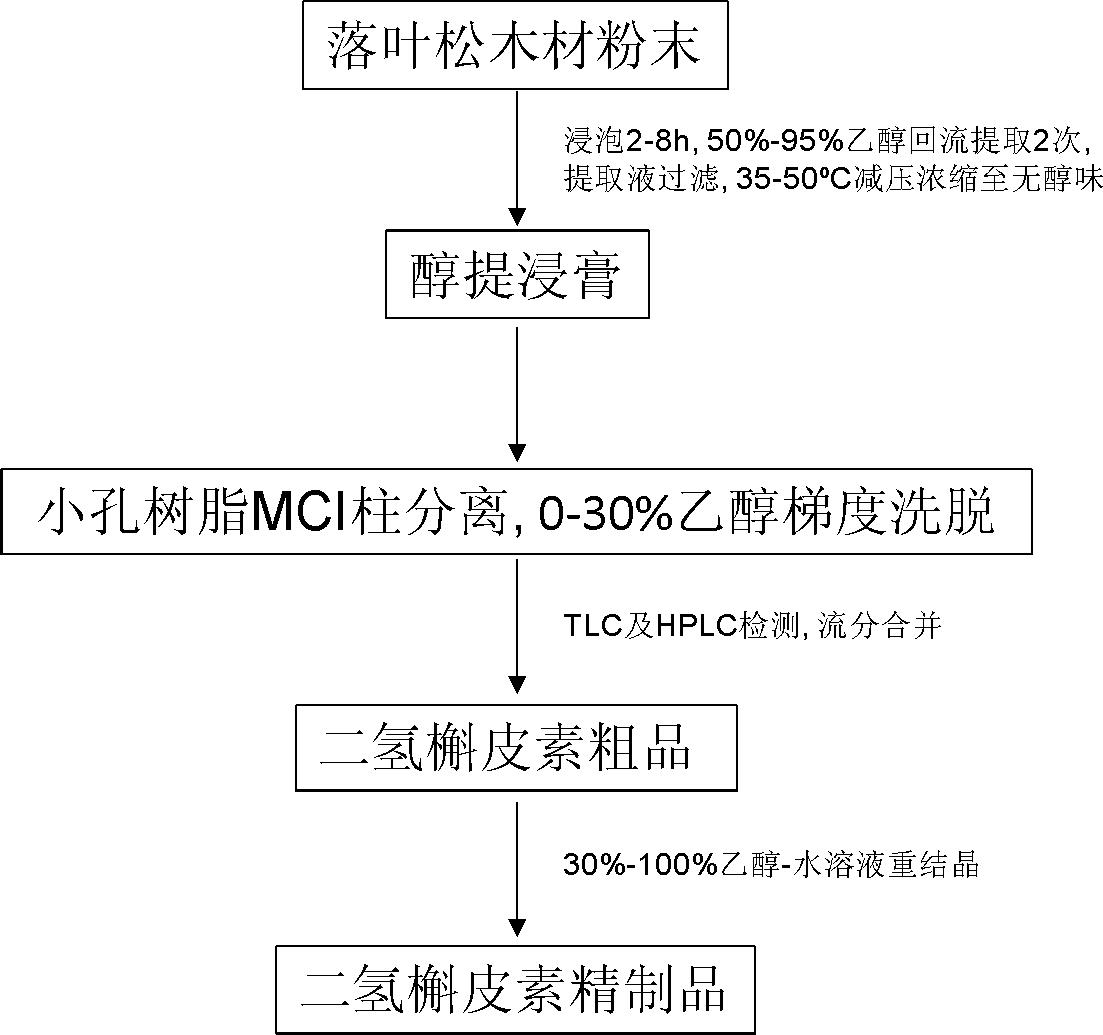

[0038] Embodiment 1: refined dihydroquercetin

[0039] (1) Extraction: 100g of larch wood powder, add 1.5L of 95% ethanol aqueous solution by volume fraction, soak for 4h, heat to reflux for 2h (80°C), filter the extract; then add 1.0L of 95% ethanol aqueous solution by volume fraction , heated to reflux for 2h (80°C), the extract was filtered and combined with the previous one, concentrated under reduced pressure at 50°C until there was no alcohol smell, and 10g of extract was obtained.

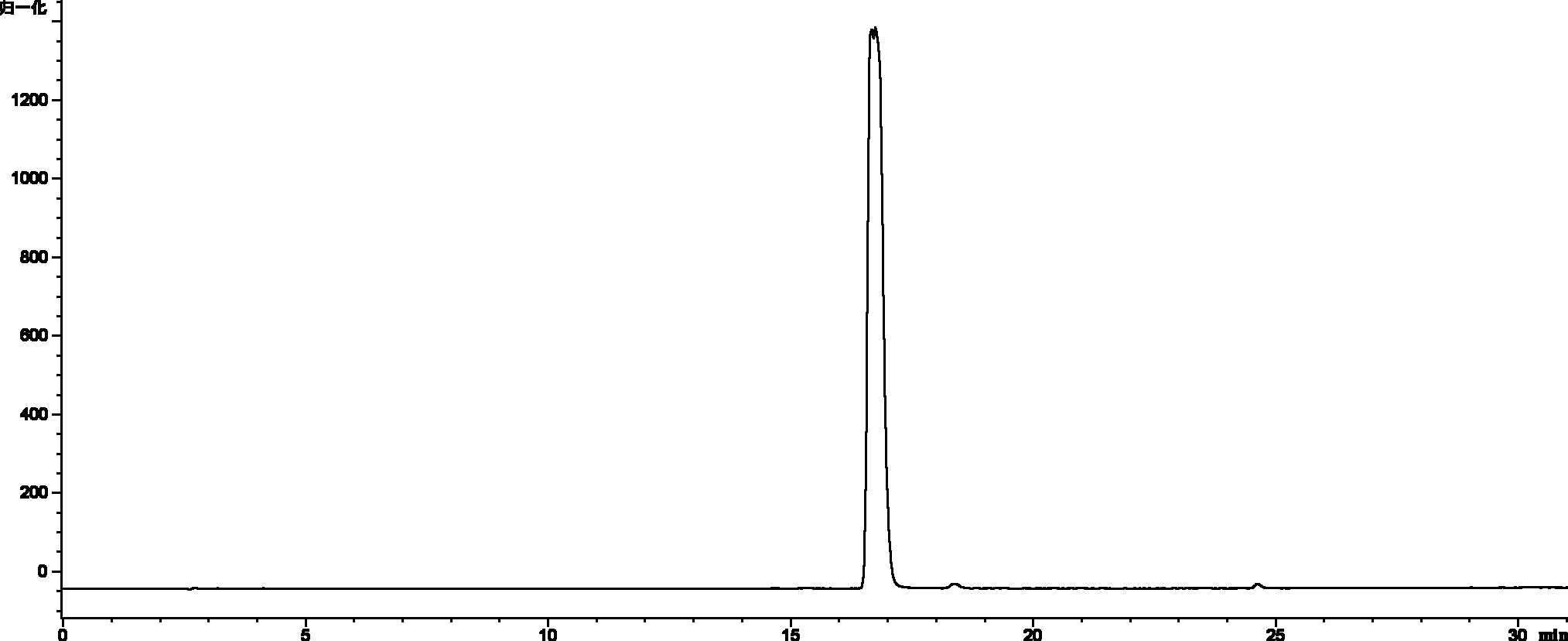

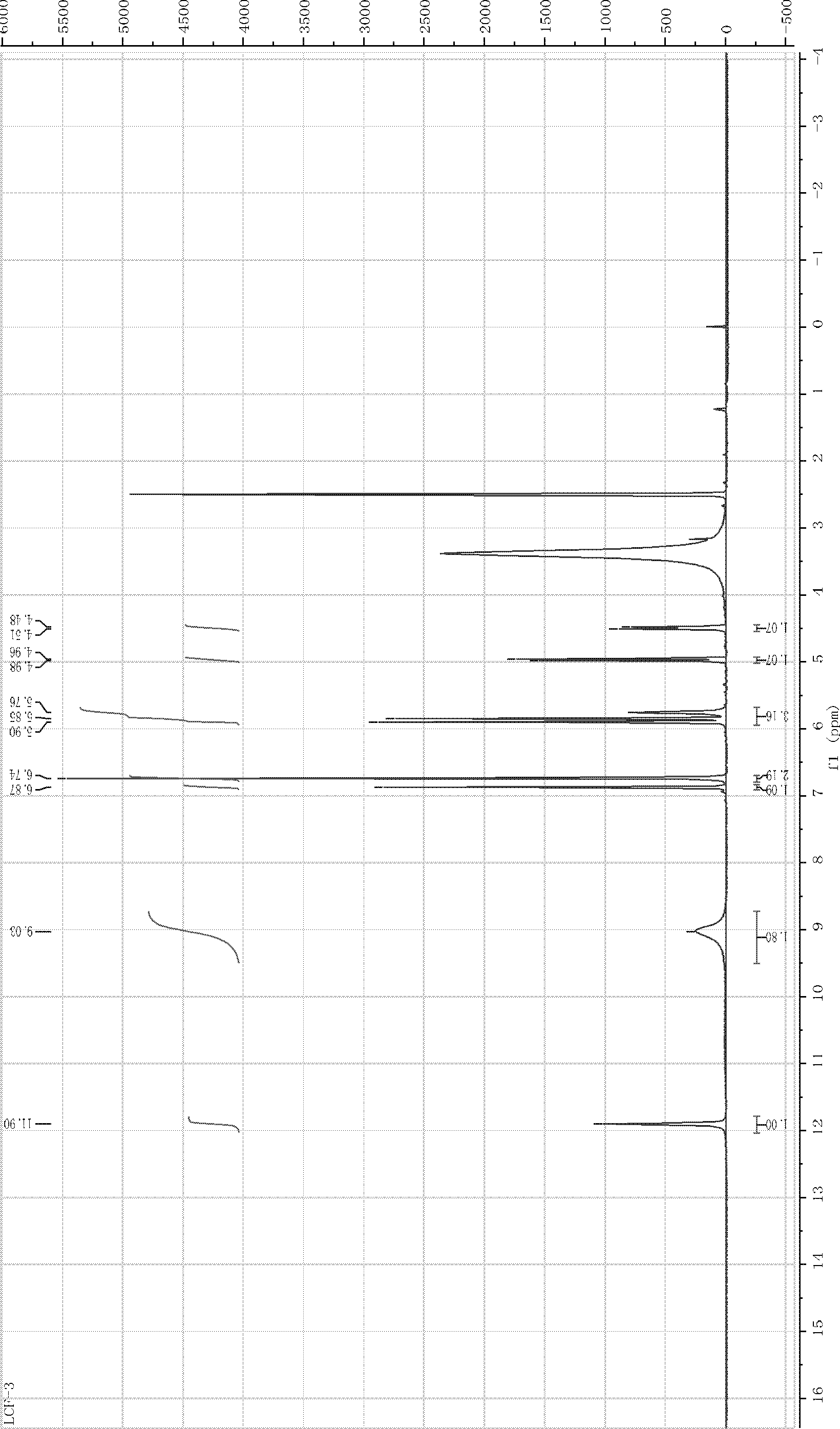

[0040] (2) Purification: The extract obtained in step (1) is subjected to liquid phase adsorption separation with a small-porous resin MCI (SBC MCI GEL, 75-150 μM, type F). Sequentially eluted with ethanol aqueous solution with a volume fraction of 10%, 20%, 25%, and 30%, and each gradient eluted with 3 column volumes. The effluent was collected and concentrated in sections, and detected by TLC. The higher fractions (20-25% elution fraction) were combined to obtain 1.57 g of dihydroquerceti...

Embodiment 2

[0043] Embodiment 2: refined dihydroquercetin

[0044] (1) Extraction: 1000g of larch wood powder, add 5L of ethanol solution with a volume fraction of 95%, soak for 4h, heat to reflux for 2h (80°C), filter the extract; then add 5L of 95% ethanol solution, heat Reflux for 2h (80°C), filter the extract and combine it with the previous one, and concentrate under reduced pressure at 35°C until there is no alcohol smell, and 100g of extract is obtained.

[0045] (2) Purification: The extract obtained in step (1) is subjected to liquid phase adsorption separation with a small-porous resin MCI (SBC MCI GEL, 75-150 μM, type F). Sequentially eluted with ethanol aqueous solution with a volume fraction of 10%, 20%, 25%, and 30%, and each gradient eluted with 5 column volumes. The effluent was collected and concentrated in sections, and detected by TLC. The higher fractions of dihydroquercetin (20-25% elution fraction) were combined to obtain 15.6 g of dihydroquercetin crude product. T...

Embodiment 3

[0048] Embodiment 3: refined dihydroquercetin

[0049] (1) Extraction: 10000g of larch wood powder, add 80L of ethanol solution with a volume fraction of 95%, soak for 4h, heat and reflux for 2h (90°C), and filter the extract; add 60L of 95% ethanol solution with volume fraction, heat Reflux for 2h (90°C), filter the extract and combine it with the previous one, and concentrate under reduced pressure at 40°C until there is no alcohol smell, and 1000g of extract is obtained.

[0050] (2) Purification: The extract obtained in step (1) is subjected to liquid phase adsorption separation with a small-porous resin MCI (SBC MCI GEL, 75-150 μM, type F). Sequentially eluted with ethanol aqueous solution with a volume fraction of 10%, 20%, 25%, and 30%, and each gradient eluted with 5 column volumes. The effluent was collected and concentrated in sections, and detected by TLC. The higher fractions (20-25% elution fraction) were combined to obtain 160 g of dihydroquercetin crude product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com