Ardealite composite material insulation board and production method thereof

A technology of composite material and phosphogypsum, applied in the field of phosphogypsum composite material insulation board and its preparation, can solve the problems of being unsuitable for practical application, complicated manufacturing process, increasing cost, etc., achieving industrial application, low production cost, Energy Saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the present invention, the present invention is further explained below in conjunction with some specific examples, and some comparative examples are given, but it should be understood that the content of the present invention is not limited to the following examples.

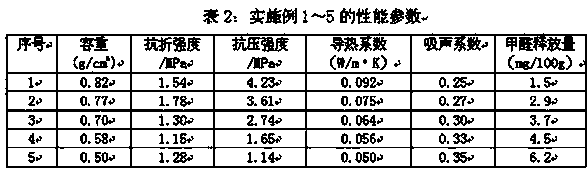

[0024] Embodiment 1~5, as shown in table 1.

[0025]

[0026] The series of preparation steps are as follows.

[0027] Step 1) Weighing.

[0028] Refer to Table 1 to weigh various raw materials. In this series of implementations, the thermosetting resin is selected from urea-formaldehyde resin; the curing agent is selected as a sulfuric acid solution with a mass fraction of 5% to 10%; A rich foam is obtained; the thickener is commercially available; the fiber is polypropylene fiber.

[0029] Step 2) Mix the ingredients.

[0030] Stir phosphogypsum, urea-formaldehyde resin, sulfuric acid solution, and stirring materials with water in a mixer at 300r / min for 3 minutes, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com