Laminated vacuum glass and manufacturing method thereof

A vacuum glass, interlayer technology, applied in the structural field of laminated vacuum glass, can solve problems such as poor adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

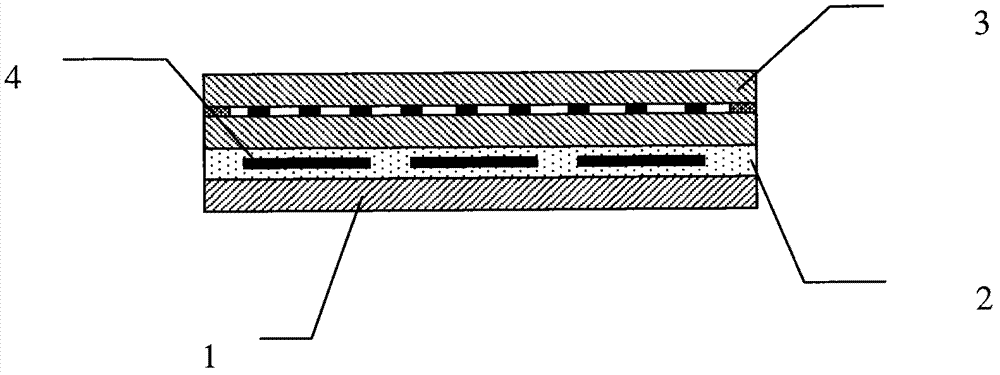

[0023] The following references are attached Figure 1-3 The specific implementation process of the method of the present invention will be described in detail.

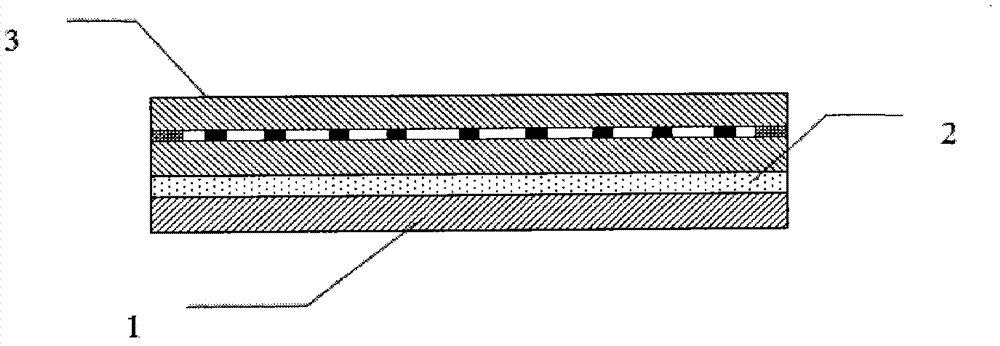

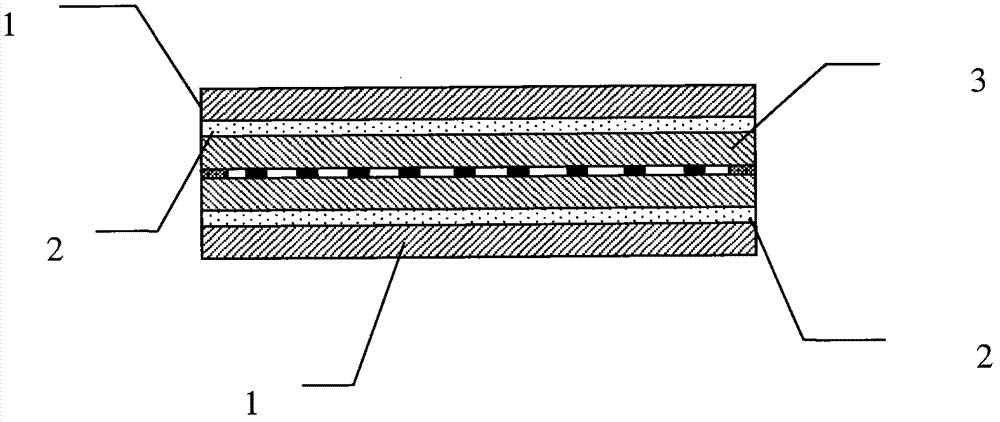

[0024] Such as figure 1 In the example 1 shown, the laminated vacuum glass to be produced includes: flat glass (such as preferably tempered glass) 1 , an interlayer interlayer 2 of PVB material, and vacuum glass 3 .

[0025] In order to make the laminated vacuum glass of the production target, the laminated vacuum glass structure must first be formed in the above-mentioned manner. Usually, an interlayer interlayer material is placed on one side of the vacuum glass 3 to form an interlayer interlayer 2, and then a piece of flat glass 1 is placed on the outer plane of the interlayer interlayer 2 to form a interlayer vacuum glass structure. In this profession, the operation steps of forming a laminated vacuum glass structure in this way are usually called "lamination (or lamination)".

[0026] Subsequently, before put...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com