Method of manufacturing PZT-based ferroelectric thin film and PZT-based ferroelectric thin film

A technology of ferroelectric thin film and manufacturing method, applied in thin film/thick film capacitors, capacitors with variable voltage, piezoelectric effect/electrostrictive or magnetostrictive motors, etc. Density and other issues to achieve the effect of preventing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

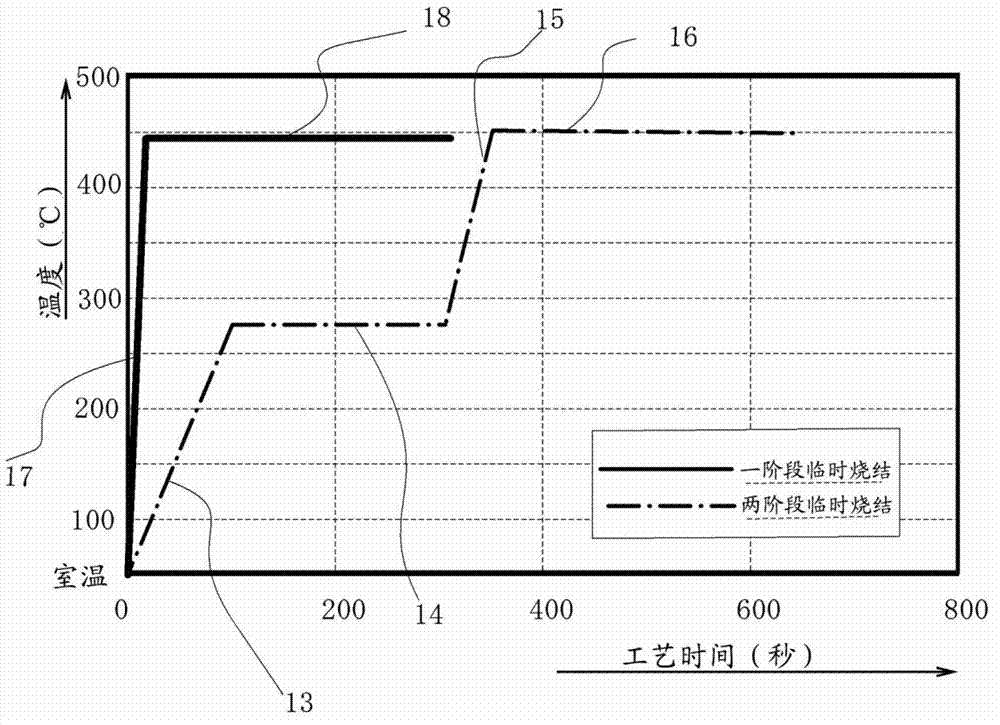

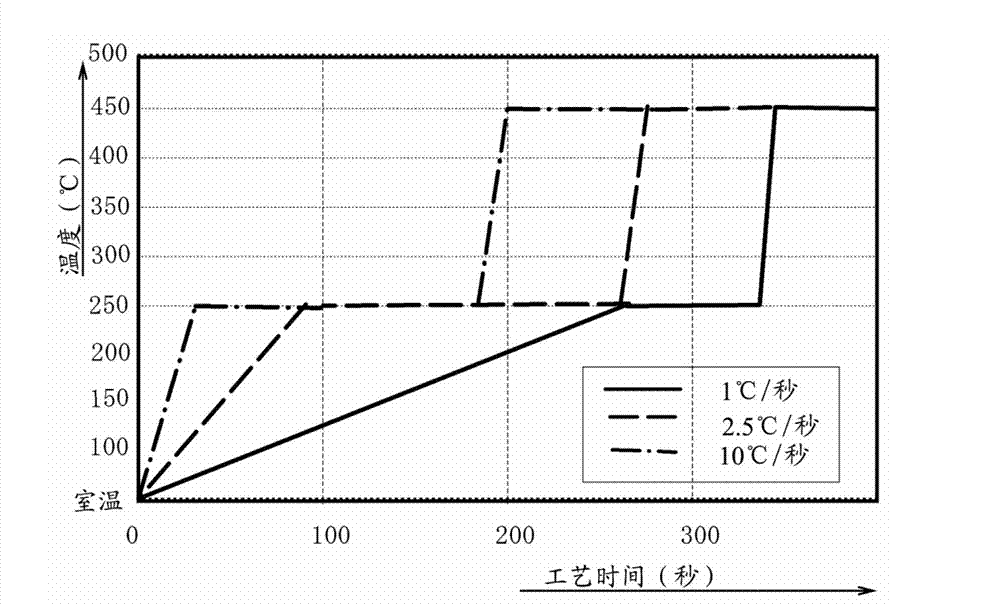

[0064] In Example 1, in the provisional sintering stage based on two-stage provisional sintering, the sol film obtained in the coating stage was provisionally sintered by infrared rays. The specific temporary sintering conditions are as follows: the temperature is raised from 25° C. to 275° C. at a rate of 1° C. / s, kept for 3 minutes, and then raised to 450° C. at a rate of 2.5° C. / s and kept for 5 minutes. Next, in the sintering stage, the amorphous film obtained in the temporary sintering is fired at a heating rate of 5° C. / second, 700° C., and a holding time of 5 minutes, thereby obtaining a PZT ferroelectric thin film.

Embodiment 2

[0066] In Example 2, in the provisional sintering stage based on two-stage provisional sintering, the sol film obtained in the coating stage was provisionally sintered by infrared rays. The specific temporary sintering conditions are as follows: the temperature is raised from 25° C. to 275° C. at a rate of 1° C. / s, kept for 3 minutes, and then raised to 450° C. at a rate of 10° C. / s and kept for 5 minutes. Next, in the sintering stage, the amorphous film obtained in the temporary sintering is fired at a heating rate of 5° C. / second, 700° C., and a holding time of 5 minutes, thereby obtaining a PZT ferroelectric thin film.

Embodiment 3

[0068] In Example 3, in the provisional sintering stage based on two-stage provisional sintering, the sol film obtained in the coating stage was provisionally sintered by infrared rays. The specific temporary sintering conditions are as follows: the temperature is raised from 25° C. to 275° C. at a rate of 1° C. / s, kept for 3 minutes, and then raised to 450° C. at a rate of 25° C. / s and kept for 5 minutes. Next, in the sintering stage, the amorphous film obtained in the temporary sintering is fired at a heating rate of 5° C. / second, 700° C., and a holding time of 5 minutes, thereby obtaining a PZT ferroelectric thin film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com