Woodworking sawing machine

A technology for woodworking saws and sawing machines, applied in the field of woodworking sawing machines, can solve problems such as production accidents, impact on cutting quality, and impact on life safety, and achieve the effects of avoiding dust flying, reducing labor usage, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

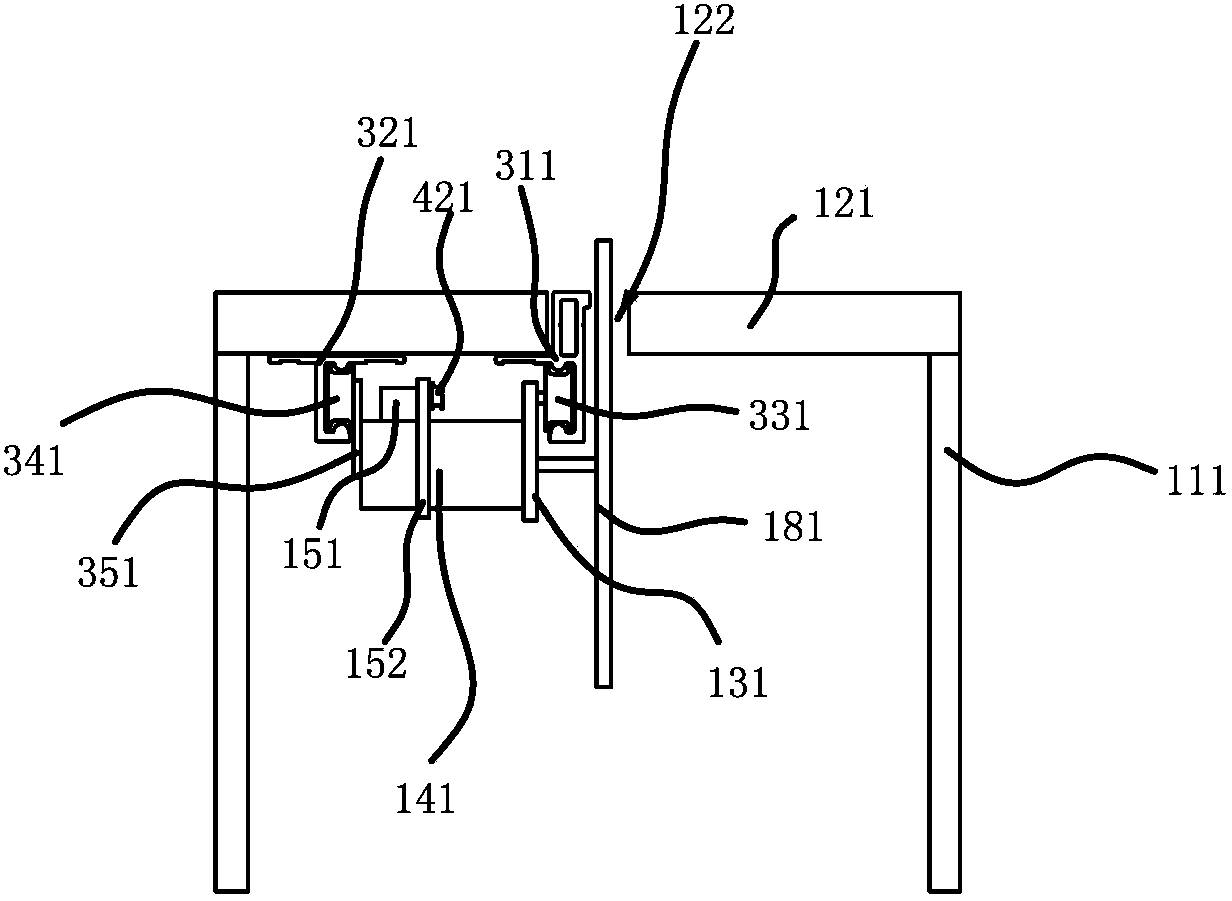

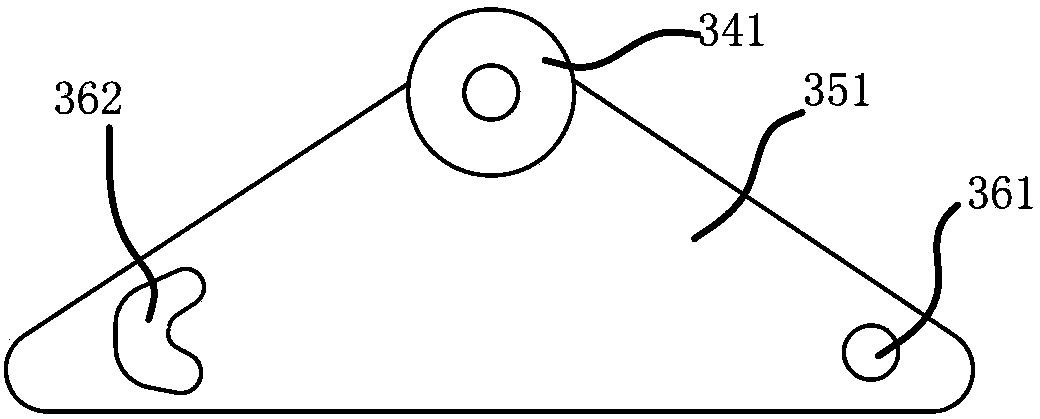

[0046] A woodworking sawing machine, the sawing machine includes a frame 111, a workbench 121 fixed on the frame 111, an electric saw with a saw blade 181 and a cutting positioning angle plate, the frame 111 and the workbench 121 are detachably fixed by screws, which is convenient Carry the sawing machine when transferring the construction site; the electric saw includes a semicircular mounting plate 131, a saw blade 181, a drive motor 141 fixed on one side of the mounting plate 131, and a handle fixed on the mounting plate 131. In the first embodiment, the driving motor 141 is a channeling motor, the saw blade 181 is located on the other side of the mounting plate 131 and fixed on the output shaft of the drive motor 141, the workbench 121 has a strip-shaped channel 122 for the saw blade 181 to pass through, and the drive motor 141 is located on the workbench 121 and can slide along the channel 122, the upper end of the saw blade 181 passes through the channel 122 and is locate...

Embodiment 2

[0064] The structure and principle of this embodiment are basically the same as that of Embodiment 1. The difference is that the drive structure includes a travel motor and a chain, the travel motor is fixed on the housing of the drive motor, and the output shaft of the travel motor is fixed with a sprocket. The two ends of the chain are respectively fixed on the frame, the chain is in a tight state, the chain is parallel to the channel, and the teeth of the sprocket are meshed with the chain. When cutting wood, the walking motor rotates to drive the sprocket to rotate, and the meshing rotation of the sprocket and the chain drives the chainsaw to move; the chain is tight, the teeth of the sprocket are always meshed with the chain, and the vibration of the chainsaw when cutting wood will not affect both. The engagement between the two, the chainsaw can move smoothly at a constant speed, making the cutting surface of the wood smooth.

Embodiment 3

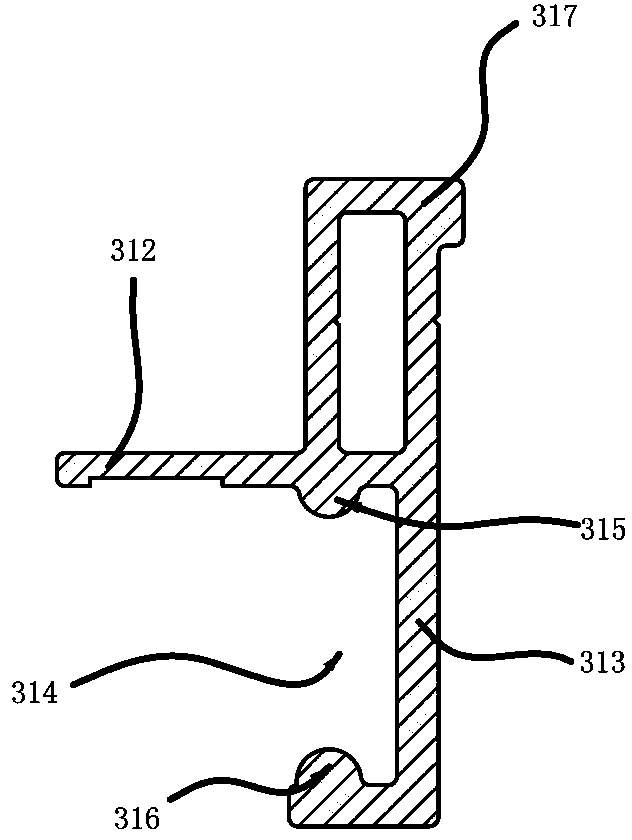

[0066] The structure and principle of this embodiment are basically the same as that of Embodiment 1. The difference is that the positioning structure includes positioning bolts and adjustment holes provided on the protractor plate. The adjustment holes are arc-shaped elongated holes. The hole is parallel to the edge of the arc, the side where the protractor disc and the rotating rod abut is the upper disc surface, the other side of the protractor disc is the lower disc surface, the hole wall of the adjustment hole is located on the lower disc surface, and an annular concave shoulder is opened, and the middle part of the rotating rod has a Positioning hole, the positioning hole is connected with the adjustment hole, the positioning bolt passes through the positioning hole and the adjustment hole, one end of the positioning bolt is against the rotating rod, the other end of the positioning bolt is threaded with a hexagon nut, and the hexagon nut nut The peripheral surface is aga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com