Dust-free machine-made natural sand manufacturing separation system and method

A separation system, a technology for machine-made sand, applied in solid separation, chemical instruments and methods, and separation of solids from solids by air flow, etc., can solve the problems of inability to achieve air-selection of machine-made sand, inability to reproduce dust-free machine-made sand, etc. To achieve the effect of shortening the time of replacing the screen, avoiding the waste of raw materials, and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

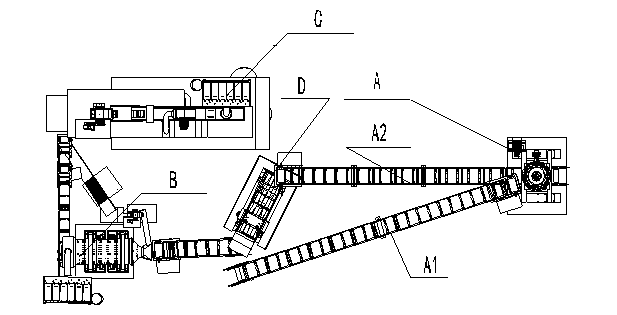

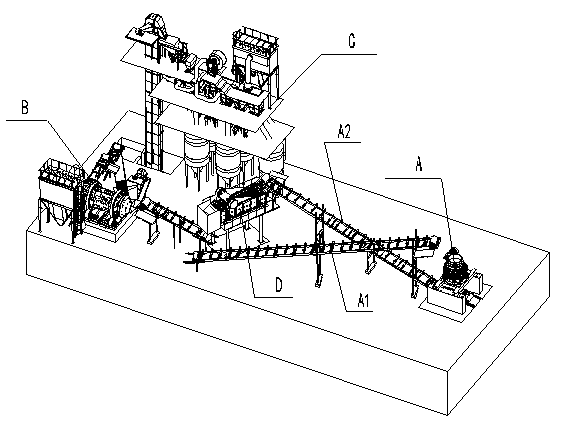

[0042] Embodiment 1: with reference to attached Picture 1-1 and 1-2 . A dust-free mechanism natural sand production and separation system, including a PLC controller, the stone passes through the stone conveying mechanism A1 to the feed port of the sand making machine A, and the discharge port of the sand making machine A is directly facing the starting end face of the machine-made sand conveying mechanism A2, and the mechanism The end of the sand conveying mechanism is directly facing the feed end of the modular multi-layer vibrating screen D, and the discharge end of the modular multi-layer vibrating screen D is directly facing the feed end of the mechanism natural sand machine matching adjustment system B, and the mechanism natural sand machine matching adjustment The discharge end of system B is directly facing the feed end of machine-made sand wind separation system C, and the discharge ports of machine-made sand with different particle sizes in machine-made sand wind se...

Embodiment 2

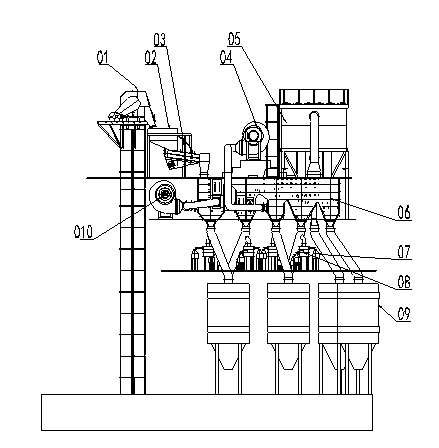

[0078] Example 2: On the basis of Example 1, a wind separation method for making natural sand with a dust-free mechanism, the stone passes through the stone conveying mechanism A1 to the feed port of the sand making machine A, and the sand making machine A makes the stone into a mechanism After the sand is discharged from the discharge port of the sand making machine A to the end face of the machine-made sand conveying mechanism A2, the end of the machine-made sand conveying mechanism A2 continuously drops the machine-made sand to the modular multi-layer vibrating screen D for screening, and the screened out The machine-made sand is transported to the machine-made natural sand machine with adjustment system B, and the machine-made natural sand machine is equipped with the adjustment system B to make the machine-made natural sand into the machine-made sand wind separation system, and the machine-made sand wind power wind separation system starts the main fan 010 and the auxiliary...

Embodiment 3

[0085] Embodiment 3: On the basis of Embodiment 2, the main tuyere located at the lower end of the feed port of the first strong wind cabin 2 is strongly supplied with wind under the action of the main fan 01, and the machine-made sand is fed by the feed chamber 23 of the first strong wind cabin. Blow into the adjacent first stage boiling chamber 24, because the two sides of the first stage boiling chamber 24 are provided with auxiliary air outlets 04 to supplement the air volume, so that the machine-made sand is continuously blown from bottom to top in the first stage boiling chamber. The wind blowing on both sides, during which the quality of the large-grained machine-made sand exceeds the blowing of the wind, so the machine-made sand of this level enters the first-stage grading storage tank 09 from the outlet 25 of the first-stage strong wind cabin, and the quality The machine-made sand that is less than the wind force is blown up through the boiling chamber into the first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com