Left wheel popup box type porous pull-down plug graphite water gap device of electromagnetic slag smelter

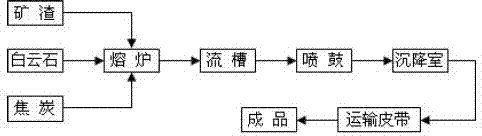

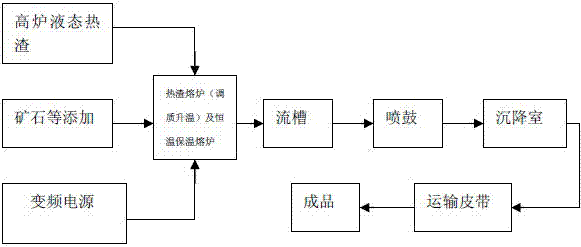

A graphite and slag technology, used in furnaces, furnace components, charge control, etc., can solve problems such as poor fluidity, inability to control high-temperature slag flow, blockage of channels, etc., achieving obvious cost advantages, superior conditioning performance, and waste slag. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

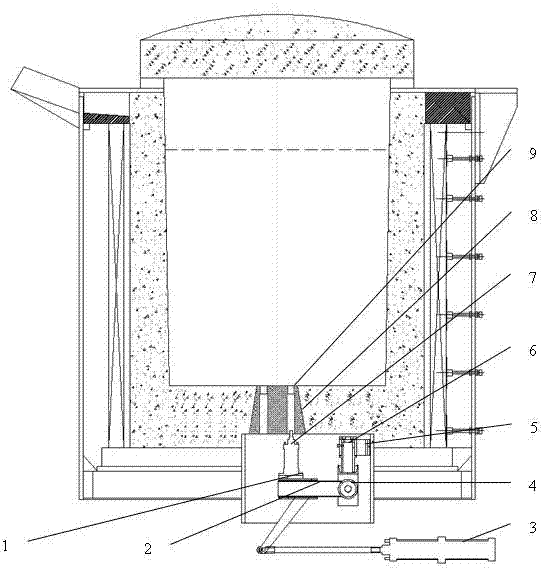

[0029] Control attached image 3 , 4 , Electromagnetic induction slag melting furnace left wheel cartridge type porous pull down plug graphite nozzle device, its structure includes moving arm 1, plug arm 2, plug cylinder 3, pin shaft 4, fixed frame 5, rotary shaft 6, top plug cylinder 7 and graphite nozzle 8, graphite plug 9; wherein graphite nozzle 8 is fixed in the furnace bottom lining, graphite plug 9 is inserted into graphite nozzle 8, top plug cylinder 7 is connected with graphite plug 9, top plug cylinder 7 Then it is fixed on the moving arm 1, and the moving arm 1 is set on the plug arm 2, which can move back and forth. The rotating shaft 6 is fixed on the fixed frame 5 and can rotate in the horizontal plane.

[0030] Working process: After the molten slag in the furnace reaches the water outlet requirement, the top plug cylinder 7 is extended to break the jelly at the bottom of the slag → the plug cylinder 3 is retracted, driving the plug arm 2, the moving arm 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com