A gas injection device with retreating gas injection point in an underground gasification system

A gas injection point retreat, underground gasification technology, applied in coal gasification, underground mining, construction, etc., can solve the problems that the gas injection point cannot be opened automatically and the staff is inconvenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

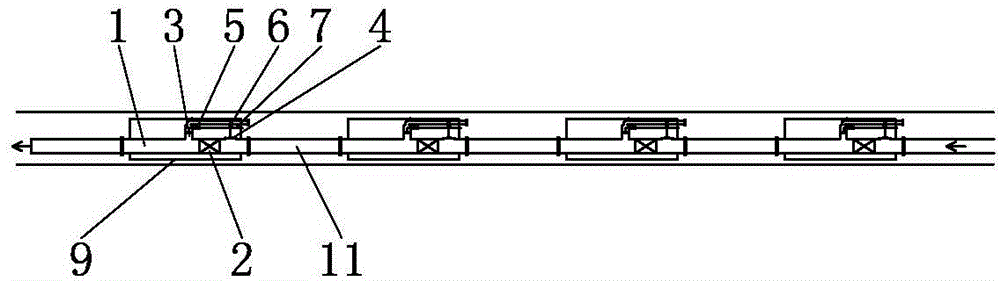

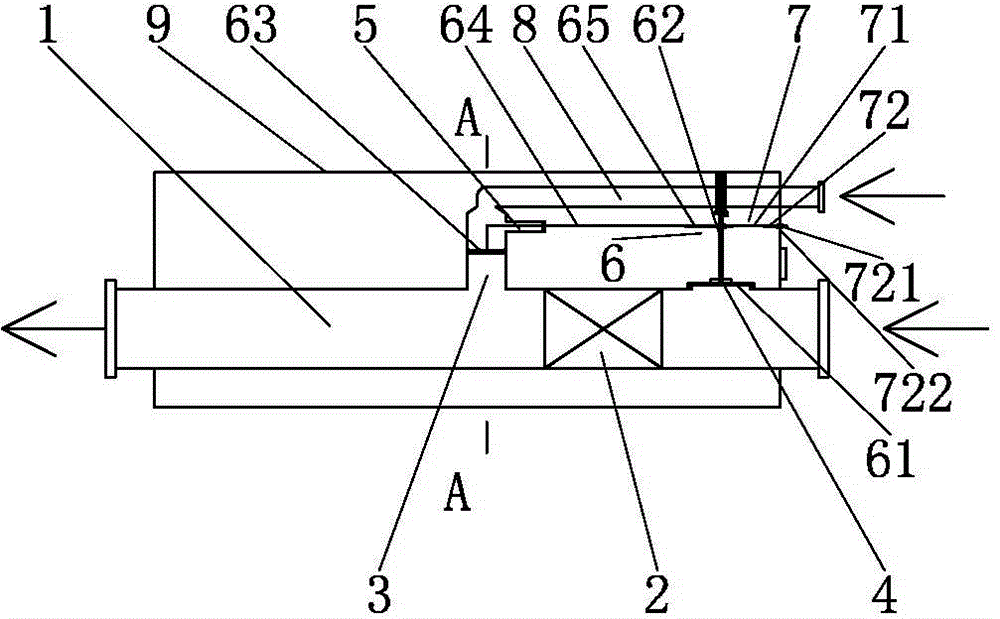

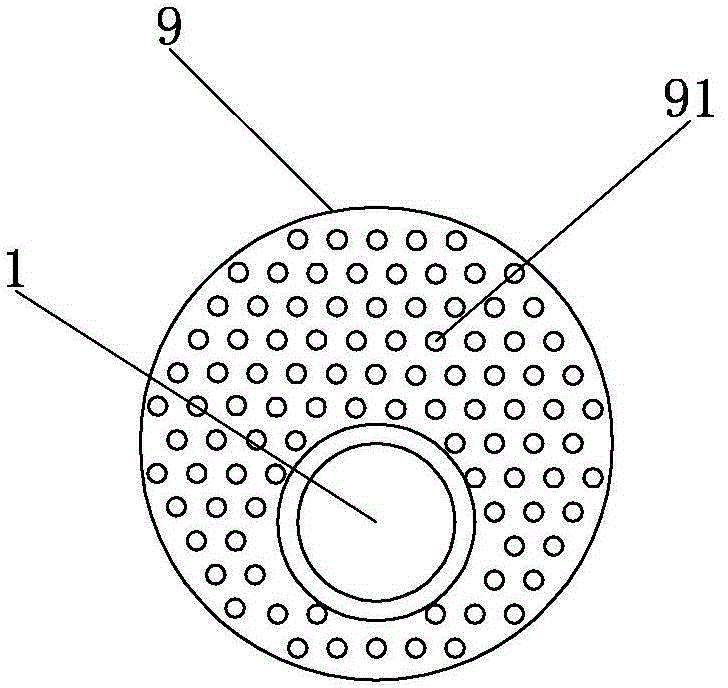

[0036] Such as Figure 1 to Figure 10 As shown, the present invention provides a gas injection point retreat type gas injection device placed in the underground gasification system in the roadway, including a gasification agent delivery pipe 1, the gasification agent delivery pipe 1 is divided into multiple sections, from figure 1 It can be seen from the figure that, preferably, two adjacent gasification agent delivery pipes 1 communicate through a connecting pipe 11 . Each section of the gasification agent delivery pipe 1 is respectively sleeved with a sleeve 9; preferably, the sleeve 9 is a cylindrical shell, from figure 2 It can be seen that the axis of the sleeve 9 and the axis of the gasification agent delivery pipe 1 are parallel to each other. Of course, the sleeve 9 can also be other shells with an upwardly convex top surface, such as spherical shells, upper hemispherical shells, upper semi-cylindrical shells, and the like. Like this, when roadway top coal seam drop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com