Oscillating mechanism of internal grinding machine

An oscillating mechanism, the technology of an internal cylindrical grinder, which is applied in the directions of grinding machine parts, grinding machines, and machine tools designed for grinding the rotating surface of workpieces, can solve problems such as affecting work efficiency and large vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

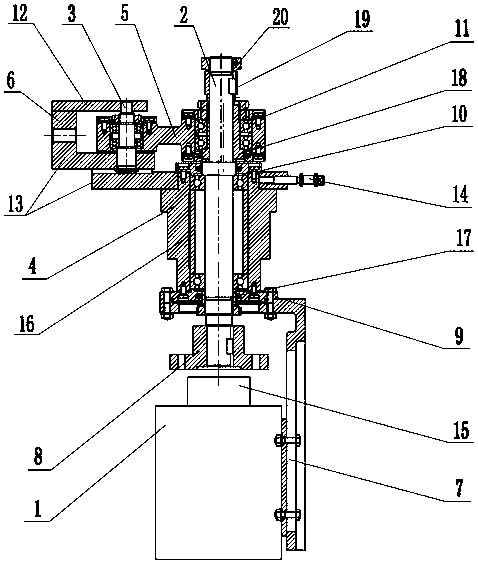

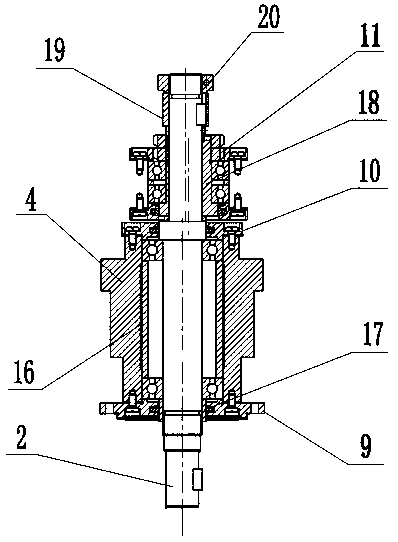

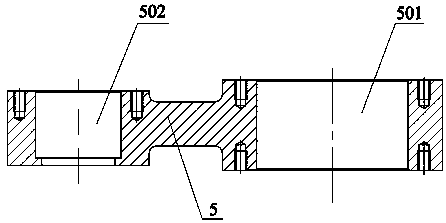

[0023] An oscillating mechanism of an internal grinding machine, structurally, includes a motor 1, an eccentric shaft 2, a small shaft 3, a shaft sleeve 4, a connecting rod 5, a supporting plate 6 and a positioning bracket 7, and the positioning bracket 7 includes an inverted The longitudinal connection plate 701 and the horizontal connection plate 702 of the L-shaped connection, the eccentric shaft positioning hole 703 is arranged on the horizontal connection plate 702, the motor 1 is fixed on the inside of the longitudinal connection plate 701 by screws, and the motor 1 is fixed on the inner side of the longitudinal connection plate 701. A reducer 15 is provided, and the motor 1 is a Y200L-4 three-phase asynchronous motor; the eccentric shaft 2 passes through the eccentric shaft positioning hole 703, and is connected to the motor 1 through a coupling 8;

[0024] Above the horizontal connecting plate 702, there are bearing end cover I9, bearing end cover II10 and bearing end c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com