Preparation method of water and oil applicable, nano transparent iron oxide yellow paste

A transparent iron oxide, water-oil general-purpose technology, applied in the treatment of dyed organic silicon compounds, dyed low-molecular organic compounds, dyed high-molecular organic compounds, etc., can solve the problems of inconvenient use and unfavorable environment for customers, and achieve environmental protection Good, good compatibility, good dispersion stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] According to Example 1 in Table 1, add deionized water, bactericide, propylene glycol, CT-115A, EFKA-1502, BYK-180 according to the formula weight ratio, stir evenly at a speed of 500r / min in a high-speed disperser, and then stir at a speed of 1000~ Add transparent iron oxide yellow powder at a high speed of 1200r / min, disperse at a high speed for 45 minutes, and then turn to a cone or rod sand mill for circular grinding for 6-10 hours until the fineness 2 Stir for 15-30 minutes; add BYK-024 at a low speed, and after the viscosity and fineness are qualified, filter and pack to obtain nano-transparent iron oxide yellow slurry for water and oil.

Embodiment 2

[0018] Example 2, Example 3 The preparation steps refer to Example 1.

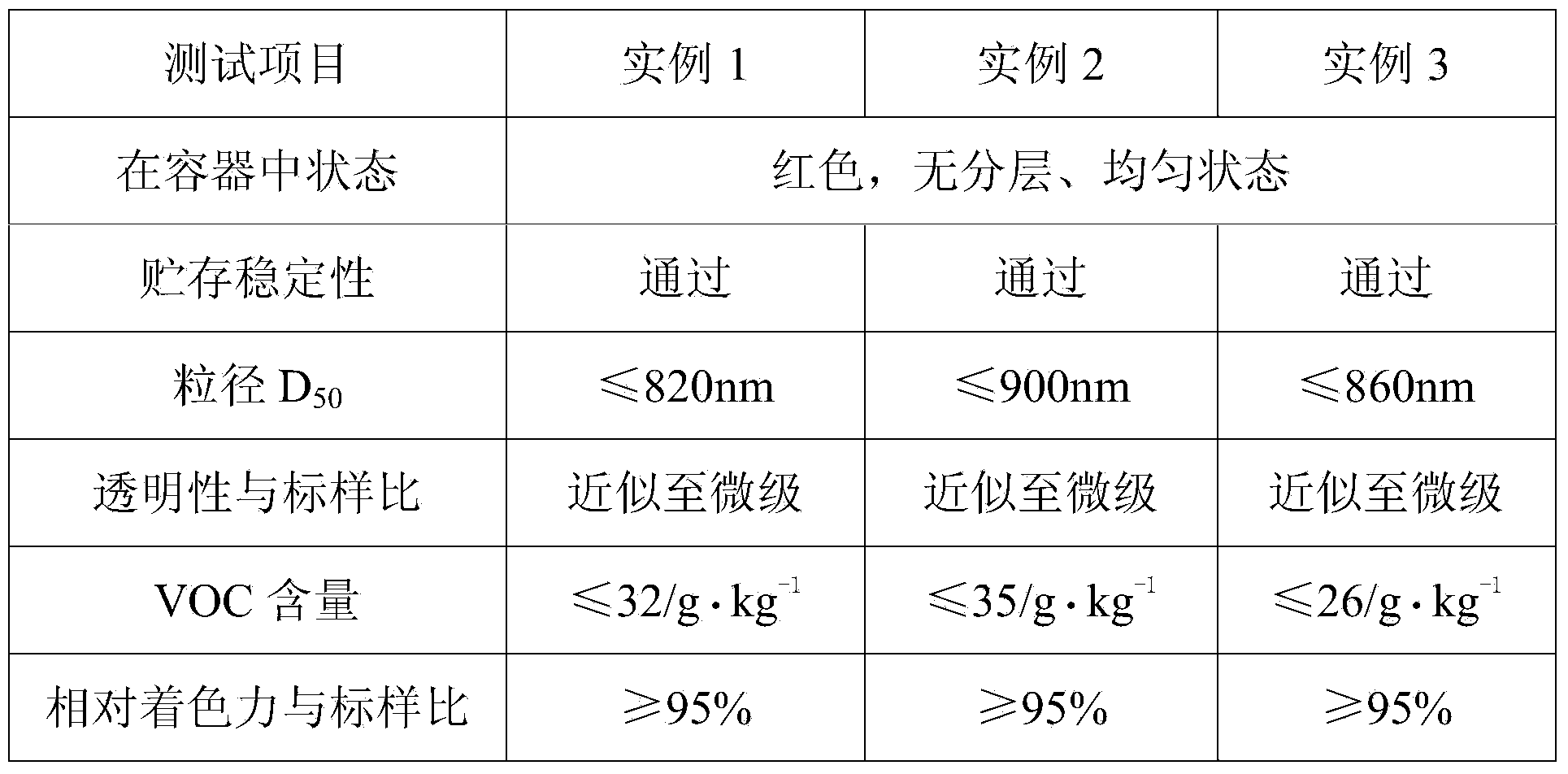

[0019] According to relevant national standards, the performance of the water-oil universal nano transparent iron oxide yellow paste of the present invention was tested, and the test results are shown in Table 2.

[0020] Table 2 Basic performance test results of water-oil universal nano-transparent iron oxide yellow slurry

[0021]

[0022] Use the compatibility test method to test the versatility of the color paste of the present invention, specifically: add 5% of the color paste to the coatings made of various emulsions and resins, and use a 200 μm wet film device after mixing evenly. The coated film board is tested by the finger grinding method. After drying, there is no floating or blooming phenomenon in the finger grinding area, and the color difference between the finger grinding area and the non-grinding area is △E≤0.5, which is considered qualified.

[0023] Emulsion or resin type ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com