Anti-puncturing safe tyre

A safety tire and tire technology, applied in tire parts, transportation and packaging, vehicle parts, etc., can solve the problems of short tire service life, poor noise reduction, poor heat dissipation, etc., to maintain air tightness and coating uniformity. Good, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

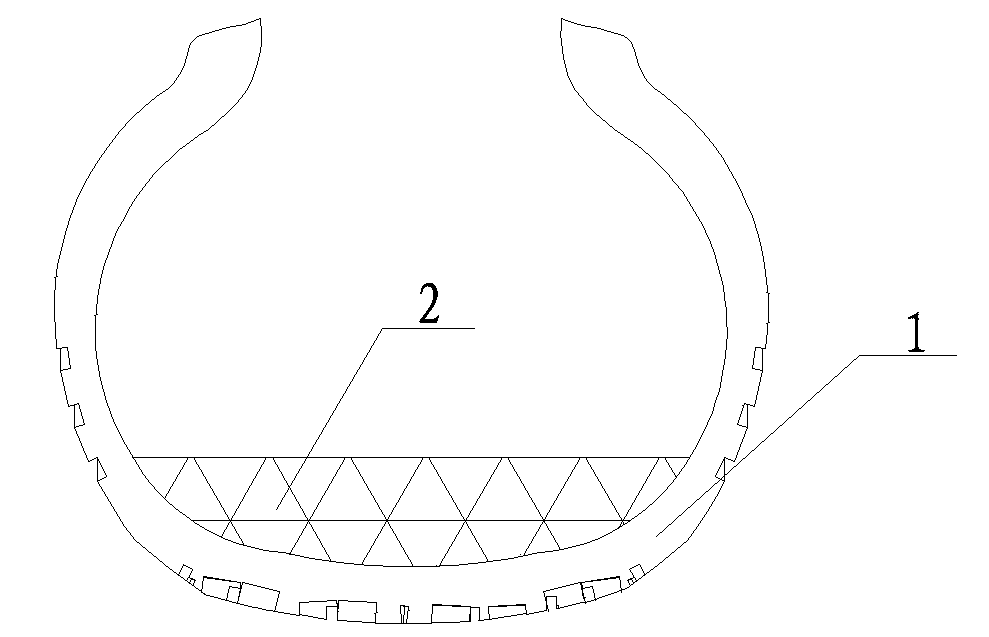

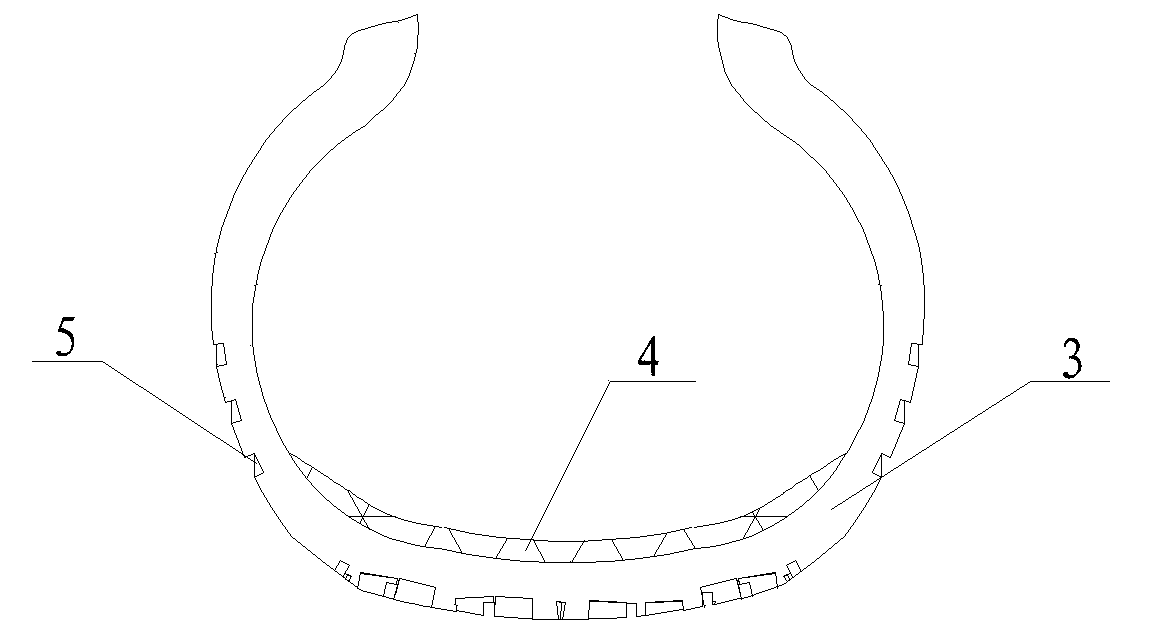

[0052] refer to Figure 2-5 , a puncture-resistant safety tire, comprising a tire carcass 3, the inner surface of the carcass 3 is evenly provided with a layer of adhesive inner coating 4, the thickness of the inner coating 4 is 3.5mm; the adhesive is polyurethane adhesive. The setting range of the inner coating 4 is the entire tire crown and extends to the first anti-scratch line 5 of the tire in the direction of the shoulder.

[0053] The manufacturing method of the anti-puncture safety tire comprises the following steps:

[0054] (1) Heat and melt the polyurethane hot melt adhesive;

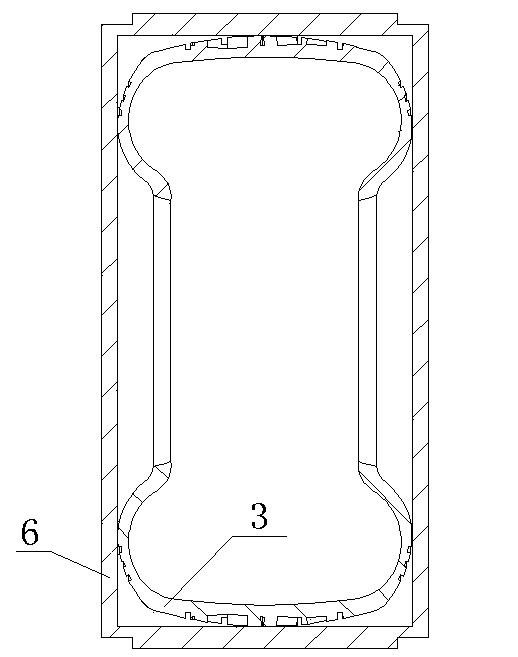

[0055] (2) Install the tire carcass 3 in the rigid cylindrical mold 6, the inner diameter of the rigid cylindrical mold is 83% of the outer diameter of the tire carcass; assemble the tire carcass 3 with the rigid cylindrical mold 6 through a certain mechanism Together, after the tire is installed, the section width of the tire increases, the outer diameter of the tire decreases, the curvatu...

Embodiment 2

[0069] refer to Figure 2-5 , a puncture-resistant safety tire, comprising a tire carcass 3, the inner surface of the carcass 3 is evenly provided with a layer of adhesive inner coating 4, the thickness of the inner coating 4 is 2.5mm; the adhesive is polyurethane Adhesive in combination with ethylene-ethyl acrylate copolymer.

[0070] The manufacturing method of the anti-puncture safety tire comprises the following steps:

[0071] (1) Heat and melt the polyurethane adhesive and ethylene-ethyl acrylate copolymer mixed adhesive with a weight ratio of 1:0.7;

[0072] (2) Install the tire carcass 3 in the rigid cylinder mold 6, the inner diameter of the rigid cylinder mold is 91% of the outer diameter of the tire carcass; The surface curvature is reduced, and the tire running surface is flatter, which is beneficial to improve the uniformity of the hot melt adhesive coating material processing;

[0073] (3) Use a spraying machine to spray the molten mixed adhesive on the inner ...

Embodiment 3

[0086] refer to Figure 2-5 , a puncture-resistant safety tire, comprising a tire carcass 3, the inner surface of the carcass 3 is evenly provided with a layer of adhesive inner coating 4, the thickness of the inner coating 4 is 0.5mm; the adhesive is poly A combination of amides and polyesters.

[0087] The manufacturing method of the anti-puncture safety tire comprises the following steps:

[0088] (1) Heat and melt the mixed adhesive of polyamide and polyester with a weight ratio of 1:1.4;

[0089] (2) Install the tire carcass in the rigid cylinder mold, the inner diameter of the rigid cylinder mold is 76% of the outer diameter of the tire carcass; after the tire is installed, the section width of the tire increases, the outer diameter of the tire decreases, and the radian of the driving surface Reduced, the tire running surface is flatter, which is beneficial to improve the uniformity of hot melt adhesive coating material processing;

[0090] (3) Use a spraying machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com