Forging forming method of fan shaft made of C250 maraging steel

A maraging steel, fan shaft technology, applied in the direction of engine components, mechanical equipment, etc., can solve the problems of unqualified structure and performance, adverse effects of forging structure and performance, etc., achieve uniform structure, eliminate work hardening process, performance high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0018] The main chemical element content (weight percentage) of C250 maraging steel (00Ni18Co8Mo5TiAl) is: C content ≤ 0.01%, Mn content ≤ 0.1%, Si content ≤ 0.1%, Ni content 17% ~ 19%, Mo content 4.6% ~ 5.2%, O content ≤ 0.002%, Al content 0.05% ~ 0.15%, Ti content 0.3% ~ 0.5%, Co content 7% ~ 8.5%, P content ≤ 0.008%, S content ≤ 0.005%, N content ≤ 0.002%, the balance is Fe.

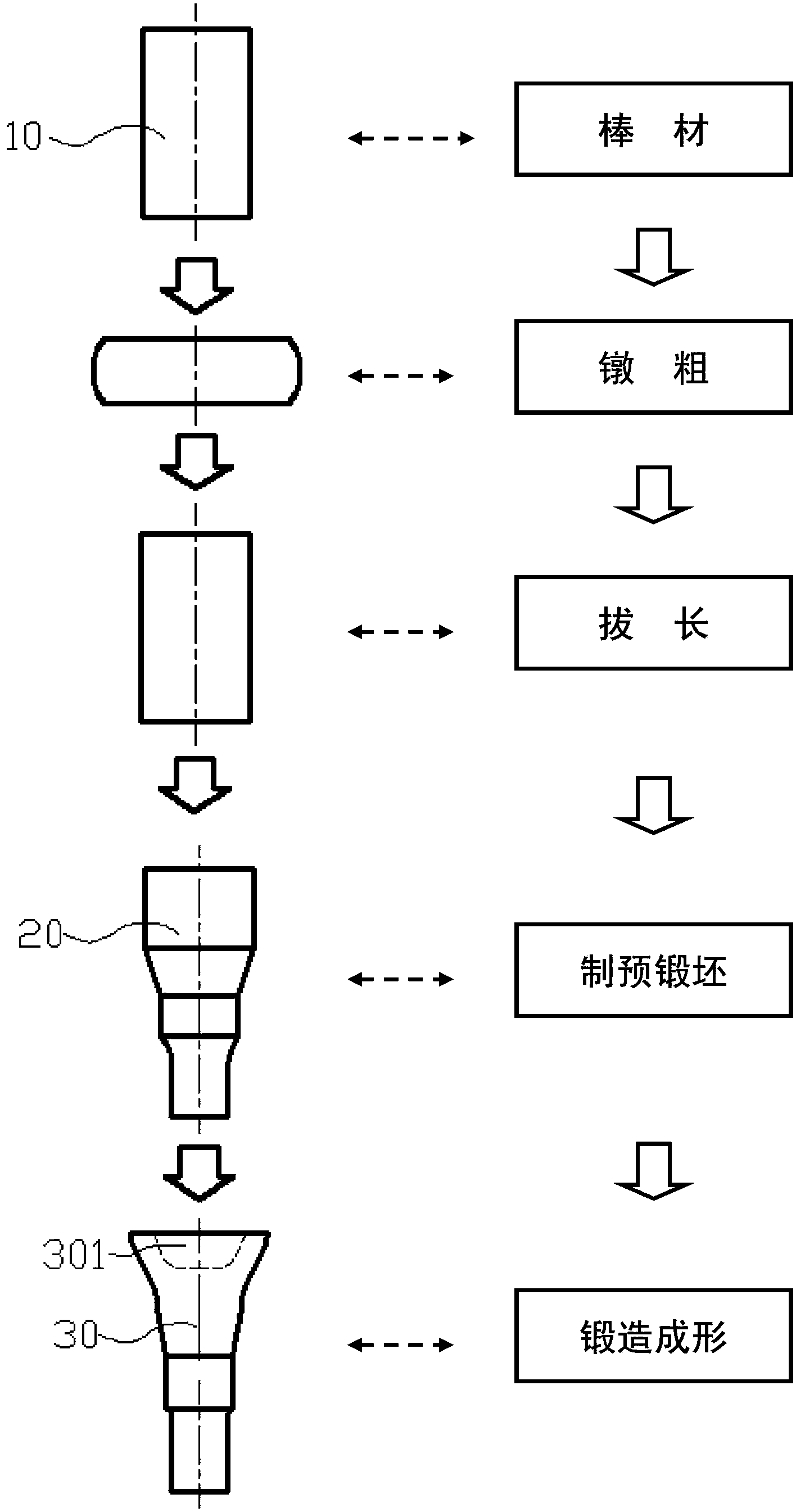

[0019] The forging process steps of the steel fan shaft forging are as follows:

[0020] Such as figure 1 As shown, the C250 maraging steel bar 10 blanked according to the specification is heated to a forging temperature of 1000°C to 1060°C, and after upsetting and elongation, it is heated to the forging temperature and then manufactured in a forging die. Form pre-forged billet 20, then heat pre-forged billet 20 to the forging temperature of 1000°C-1020°C, and then place it in the forging die for 0.01s -1 ~0.001s -1 The strain rate of forging blank 20 is formed into fan shaft forging 30 with a cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com