Radiation-sensitive composition, cured film, and method for forming same

A radiation-sensitive and compositional technology, which is applied in photosensitive material processing, instruments, optics, etc., can solve the problems that it is difficult to fully meet the required characteristics and uses of protective films or interlayer insulating films.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0344] Although the synthesis examples and examples are shown below and the present invention will be described more specifically, the present invention is not limited to the following examples.

[0345] The weight average molecular weight (Mw) and the number average molecular weight (Mn) of the polysiloxane obtained by each synthesis example below were measured by the gel permeation chromatography (Gel Permeation Chromatography, GPC) of the following specification.

[0346] Device: GPC-101 (manufactured by Showa Denko Co., Ltd.)

[0347] Column: connect GPC-KF-801, GPC-KF-802, GPC-KF-803 and GPC-KF-804 (manufactured by Showa Denko Co., Ltd.)

[0348] Mobile Phase: Tetrahydrofuran

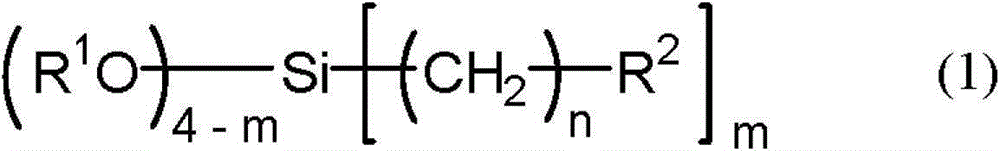

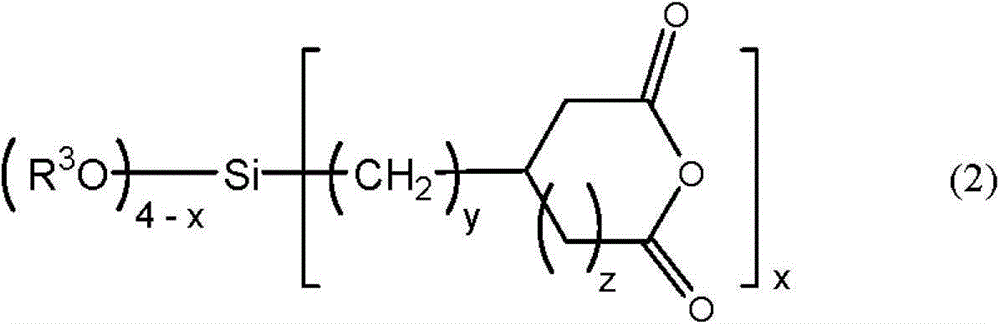

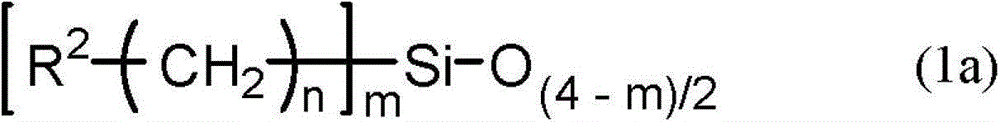

[0349] Synthesis example of polysiloxane of component [A]

Synthetic example 1

[0351] Add 20 parts by mass of propylene glycol monomethyl ether to a container with a stirrer, then add 41 parts by mass of methyltrimethoxysilane (hereinafter referred to as "MTMS"), 12 parts by mass of tetraethoxysilane (TEOS) and 3- (Trimethoxysilyl)propyl succinic anhydride (hereinafter referred to as "TMSPS") 5 parts by mass (MTMS / TEOS / TMSPS (molar ratio) = 80 / 15 / 5), heated until the solution temperature reached 60°C. After the solution temperature reached 60° C., 0.1 parts by mass of phosphoric acid and 19 parts by mass of ion-exchanged water were added, heated to 75° C., and kept for 3 hours. After cooling to 45 degreeC, 28 mass parts of methyl orthoformates were added as a dehydrating agent, and it stirred for 1 hour. Furthermore, the temperature of the solution was adjusted to 40° C., and the solution was evaporated while maintaining the temperature, thereby removing ion-exchanged water and methanol generated by hydrolytic condensation. Polysiloxane (A-1) was obtain...

Synthetic example 2

[0353]In addition to MTMS, TEOS, and TMSPS, 3-methacryloxypropyltrimethoxysilane (hereinafter referred to as "MPTMS") is further mixed with MTMS / TEOS / MPTMS / TMSPS (molar ratio) = 68 / 15 / 15 The polysiloxane (A-2) was obtained by the operation similar to the synthesis example 1 except having used in the ratio of / 2. The polysiloxane (A-2) had a solid content concentration of 30% by mass, a weight average molecular weight (Mw) of 2,300, and a degree of dispersion (Mw / Mn) of 2.1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com