Preparation method of flexible carbon counter electrode of dye-sensitized solar cell, flexible carbon counter electrode and battery

A technology for solar cells and dye sensitization, applied in the field of dye-sensitized solar cells, can solve the problems of unfavorable improvement of the photoelectric performance of dye-sensitized solar cells, poor bonding force between a conductive film layer and a flexible conductive film, and it is difficult to realize the effective effect of the conductive film layer. connection and other issues to achieve the effect of improving photoelectric conversion efficiency, achieving effective connection and avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

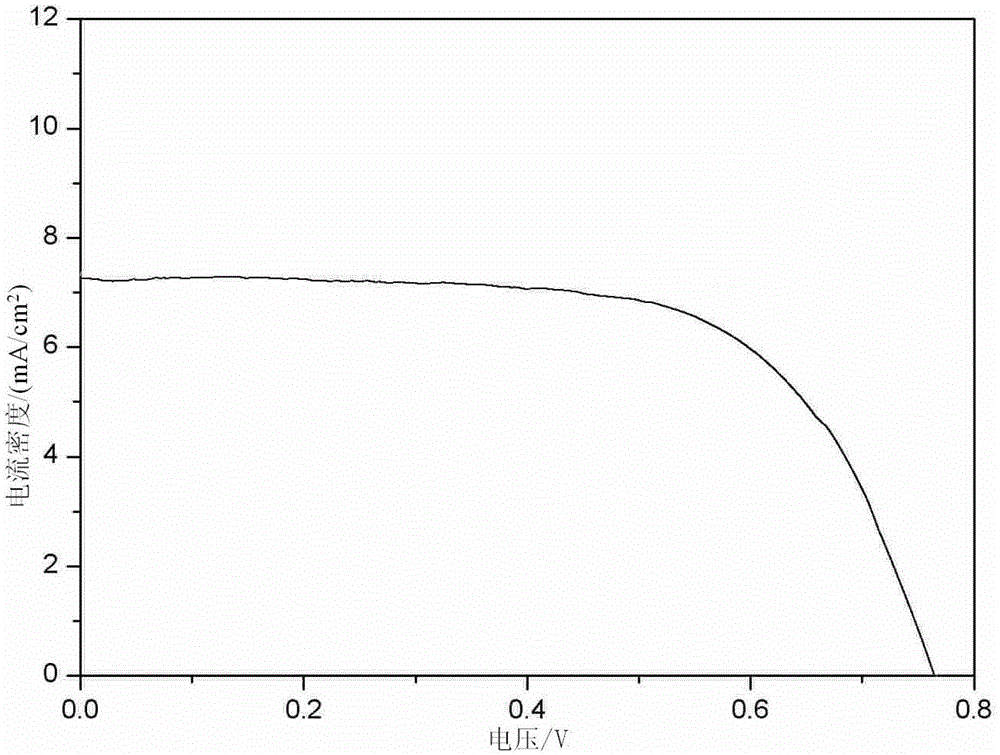

Embodiment 1

[0029] This embodiment provides a method for preparing a flexible carbon counter electrode of a dye-sensitized solar cell, comprising the following steps:

[0030] The flexible conductive substrate is pretreated to remove organic and inorganic substances on the surface of the flexible conductive substrate. The pretreatment process may be: the flexible conductive substrate is ultrasonically cleaned with acetone, ethanol, and water for 30 minutes to remove oil stains and inorganic substances on the surface for use. Among them, the flexible conductive substrate is preferably ITO / PET.

[0031] The activated carbon is added into a ball mill for dry milling, the rotational speed of the ball mill is controlled to be 800 rpm, and the milling time is 30 hours to obtain activated carbon powder.

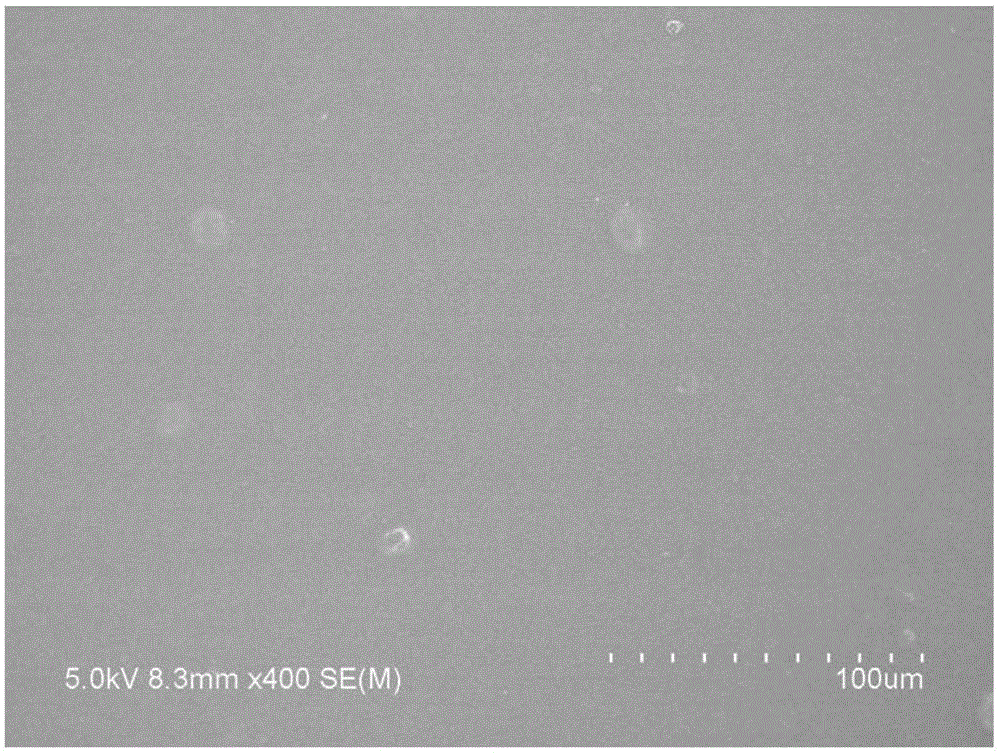

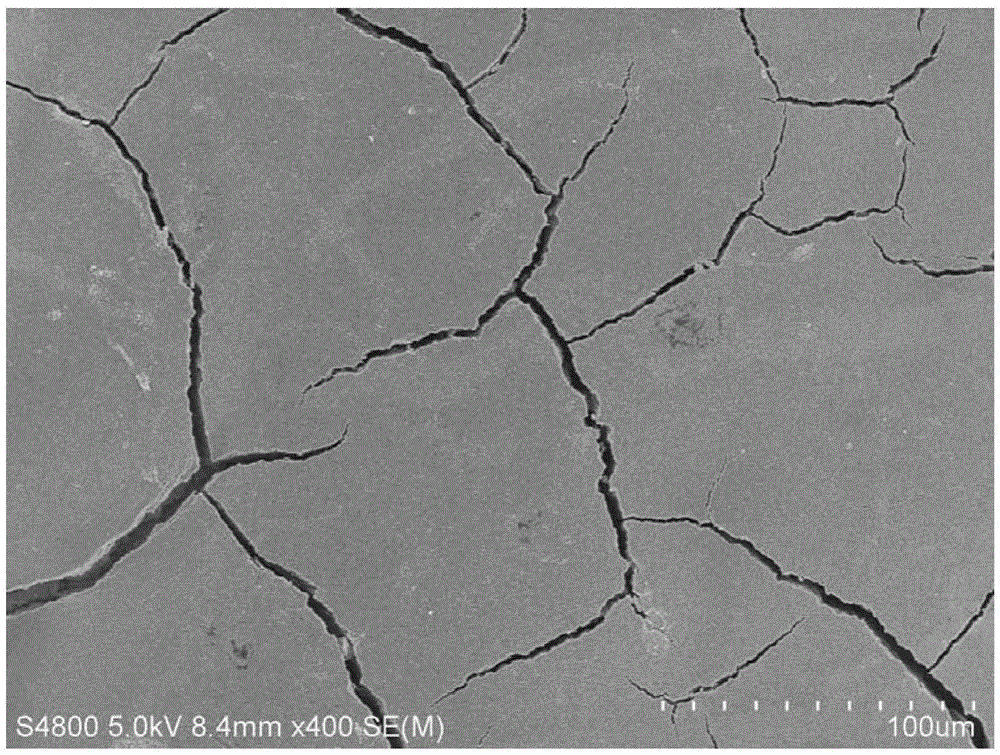

[0032] The powder material of active carbon is packed in the feeding tank of the spray gun that cold spraying method is used, the pressure of the gas that adjusts spraying in the cold spraying...

Embodiment 2

[0035] This embodiment provides a method for preparing a flexible carbon counter electrode of a dye-sensitized solar cell, comprising the following steps:

[0036] The flexible conductive substrate is pretreated to remove organic and inorganic substances on the surface of the flexible conductive substrate. The pretreatment process may be: the flexible conductive substrate is ultrasonically cleaned with acetone, ethanol, and water for 30 minutes to remove oil stains and inorganic substances on the surface for use. Among them, the flexible conductive substrate is preferably ITO / PEN.

[0037]Put the glassy carbon into a ball mill for dry grinding, control the ball milling speed to 1500 rpm, and the ball milling time to 25 hours to prepare glassy carbon powder.

[0038] The powder material of glassy carbon is packed in the feeding tank of the spray gun that cold spraying method is used, the pressure of the gas that adjusts spraying in the cold spraying method is 0.3MPa, and the s...

Embodiment 3

[0040] This embodiment provides a method for preparing a flexible carbon counter electrode of a dye-sensitized solar cell, comprising the following steps:

[0041] The flexible conductive substrate is pretreated to remove organic and inorganic substances on the surface of the flexible conductive substrate. The pretreatment process may be: the flexible conductive substrate is ultrasonically cleaned with acetone, ethanol, and water for 30 minutes to remove oil stains and inorganic substances on the surface for use. Among them, the flexible conductive substrate is preferably ITO / PET.

[0042] Weigh mesoporous carbon and microporous carbon respectively, mix mesoporous carbon and microporous carbon according to the mass ratio of 1:1, put them into a ball mill for dry milling, control the ball milling speed to 900 rpm, and ball milling time to 18 hours to obtain Mixed powder of mesoporous carbon and microporous carbon.

[0043] The mixed powder of mesoporous carbon and microporous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com