Strontium magnesium-doped nano-hydroxyapatite and preparation method thereof

A nano-hydroxyapatite, strontium-magnesium nanotechnology is applied in the field of strontium-magnesium-containing nano-hydroxyapatite and its preparation, which can solve the problems of slow reaction speed, large product particle size, low product purity, etc. Repair cycle, improve solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

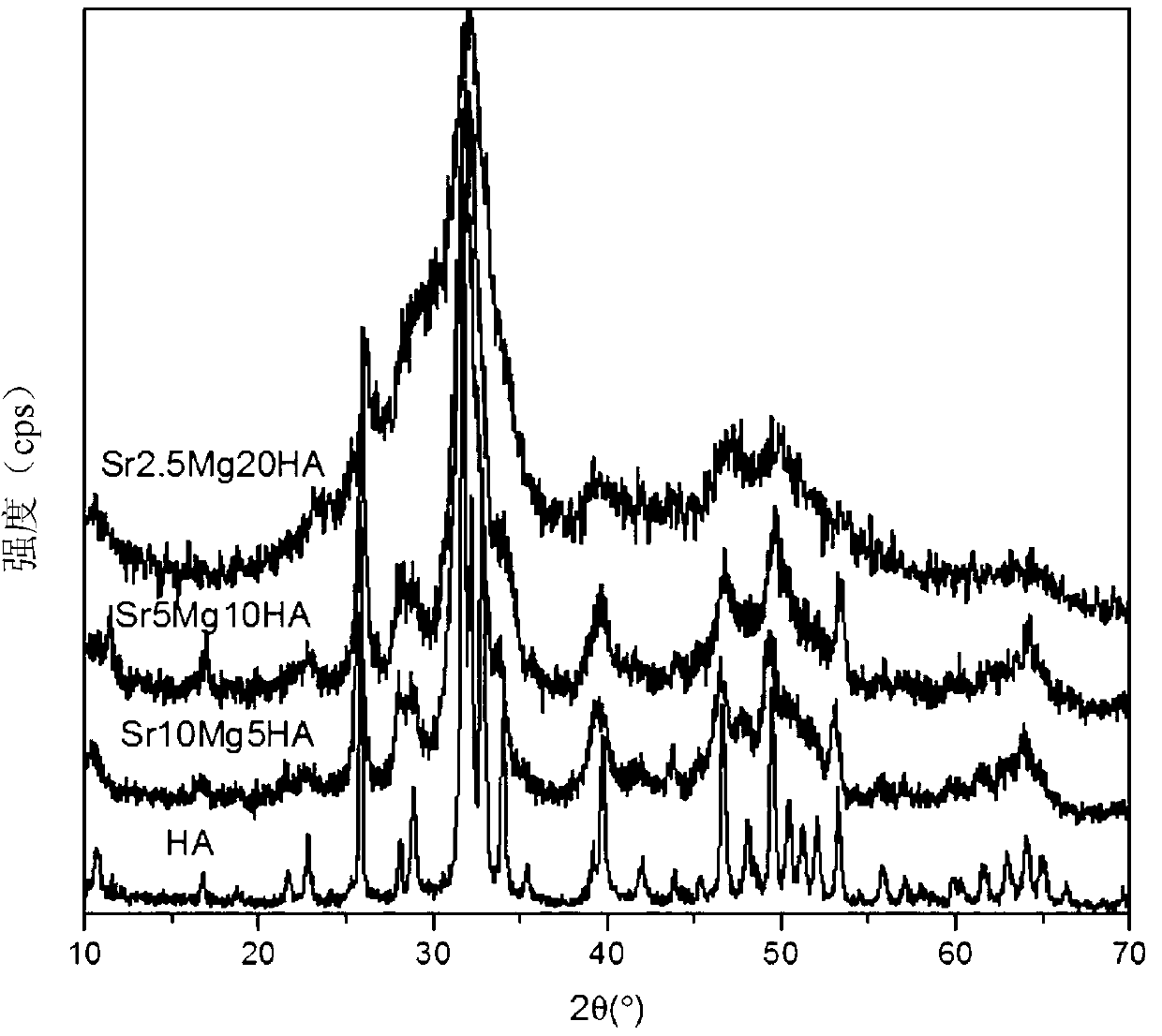

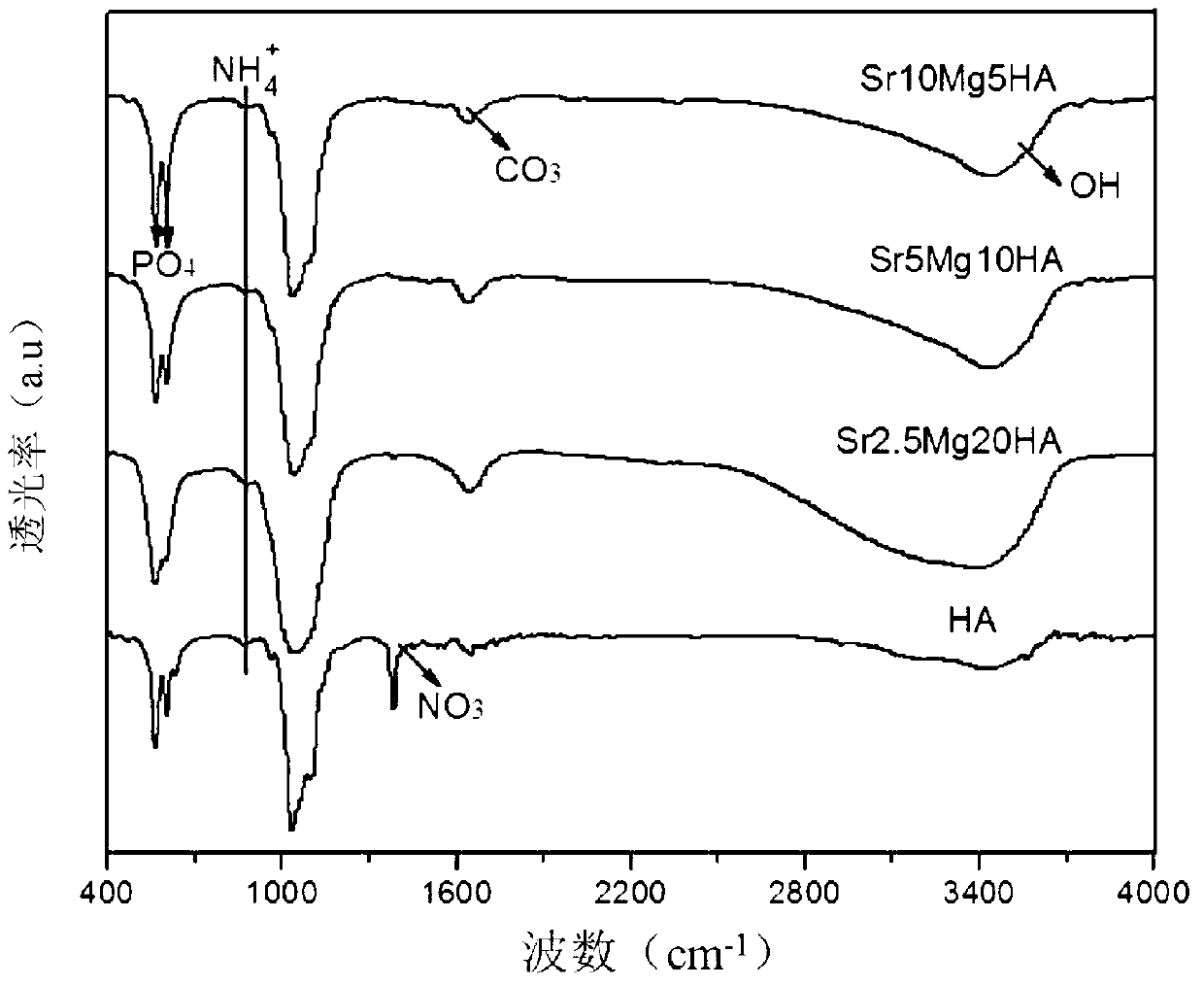

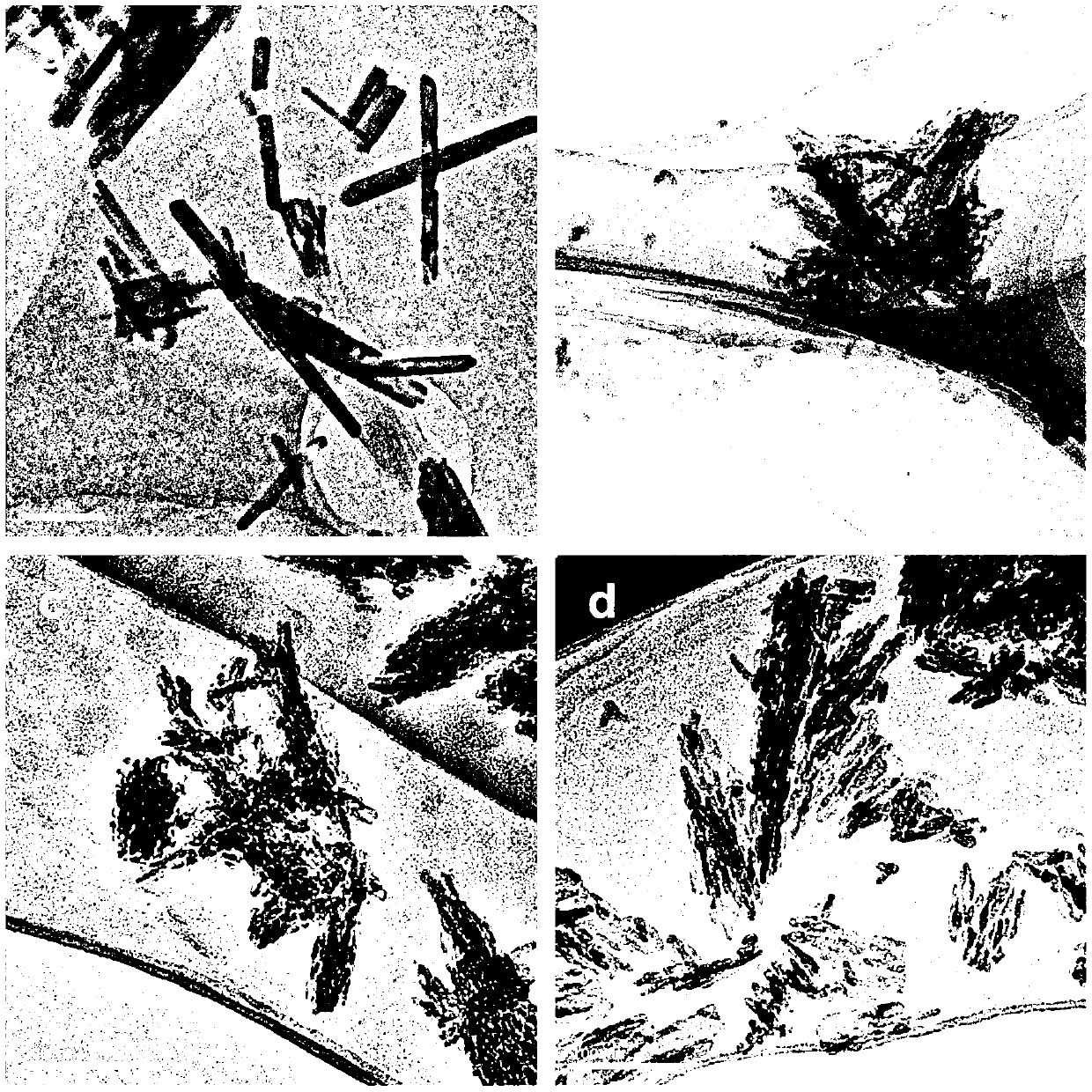

Embodiment 1

[0019] Add 23.6g of calcium nitrate into deionized water to prepare liquid A; dissolve 9.12g of ammonium hydrogen phosphate in deionized water to prepare liquid B; slowly add liquid B to liquid A at 90°C, and use ammonia water under continuous stirring Adjust the pH value to 7-8, react for 2 hours, let it stand for 24 hours, filter and wash the precipitate, put it in a reaction kettle at 80°C for 4 hours, wash the obtained slurry with deionized water, and dry at room temperature to obtain nano-hydroxyapatite .

Embodiment 2

[0021] Add 23.6g of calcium nitrate into deionized water to prepare liquid A; dissolve 0.53g of strontium nitrate in deionized water to prepare liquid B; dissolve 5.12g of magnesium nitrate in deionized water to prepare liquid C; dissolve 11.10g of hydrogen phosphate Dissolve ammonium in deionized water to prepare liquid D; slowly add liquid B, liquid C, and liquid D to liquid A at 90°C at the same time, adjust the pH value to 7-8 with ammonia water under continuous stirring, react for 2 hours, and statically After 24 hours, the precipitate was filtered and washed, and placed in a reaction kettle at 80°C for 4 hours. The obtained slurry was washed with deionized water and dried at room temperature to obtain nano-hydroxyapatite containing 2.5% strontium and 20% magnesium.

Embodiment 3

[0023] Add 23.6g of calcium nitrate into deionized water to make liquid A; dissolve 1.06g of strontium nitrate in deionized water to make liquid B; dissolve 2.56g of magnesium nitrate in deionized water to make liquid C; dissolve 10.49g of hydrogen phosphate Dissolve ammonium in deionized water to prepare liquid D; slowly add liquid B, liquid C, and liquid D to liquid A at 90°C at the same time, adjust the pH value to 7-8 with ammonia water under continuous stirring, react for 2 hours, and statically After standing for 24 hours, the precipitate was filtered and washed, and placed in a reaction kettle at 80°C for 4 hours. The resulting slurry was washed with deionized water and dried at room temperature to obtain nano-hydroxyapatite containing 5% strontium and 10% magnesium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com