Monodisperse superparamagnetic nano crystal colloidal core-shell composite particles and preparation method thereof

A technology of composite particles and nanocrystals, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve problems such as the reduction of repulsive force distance, the influence of ionic strength and pH value, and improve the resistance Ability, high chemical and colloidal stability, wide color range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048]Add glucose and polyvinylpyrrolidone to ethylene glycol to prepare a uniform mixed solution, the concentration of glucose is 10g / L, and the concentration of polyvinylpyrrolidone is 100g / L. Add ferric chloride hexahydrate into the mixed solution, stir until completely dissolved, the concentration of ferric ion in the solution is 4.6g / L, add an appropriate amount of anhydrous sodium acetate to adjust the pH of the system to 8.0. Then put it into a reaction kettle, seal it and heat it to 200°C, keep it warm for 12 hours, cool it down to room temperature, wash and separate it with ethanol for 2-3 times, and dry the solid in vacuum to get the product.

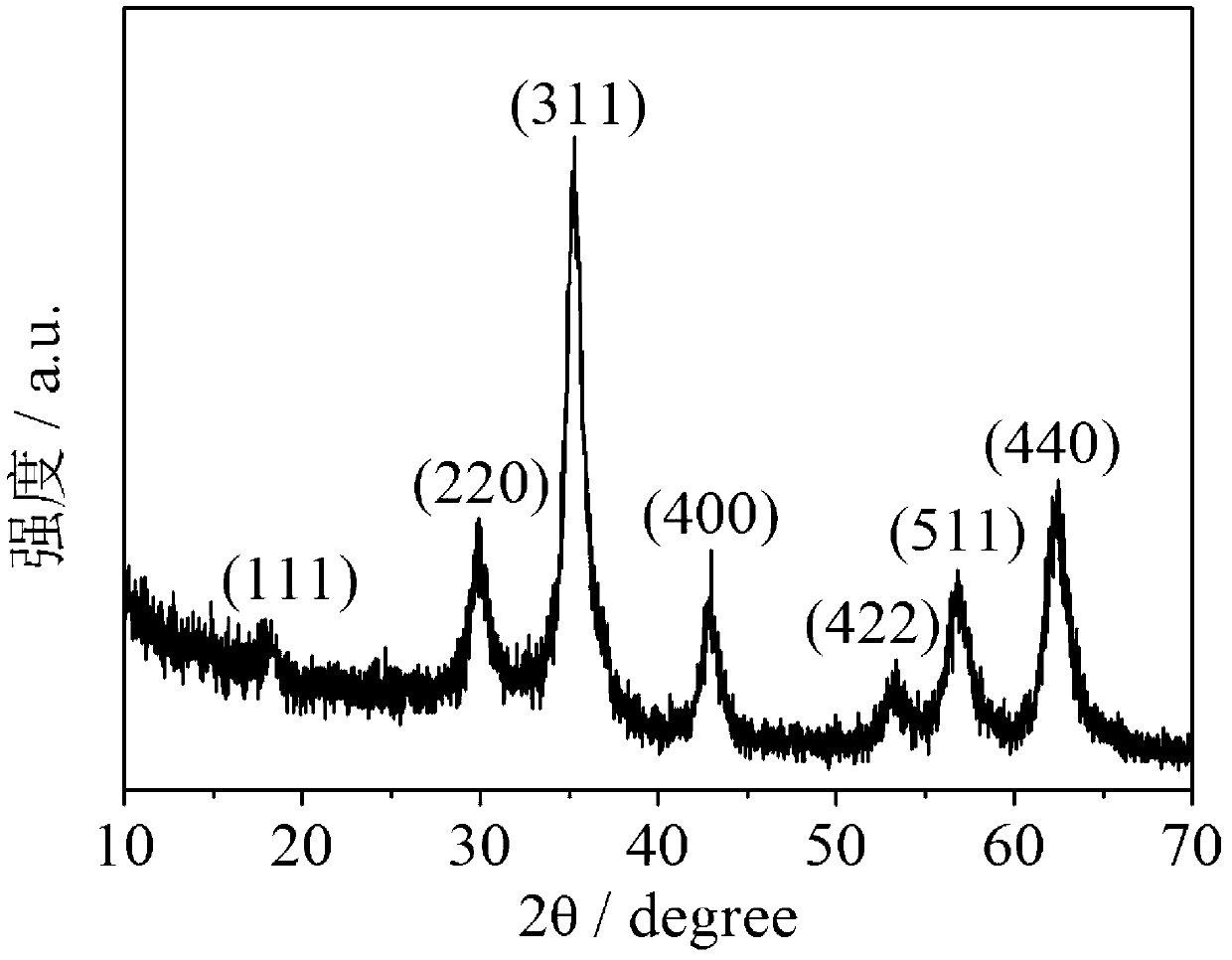

[0049] according to figure 1 From the field emission scanning electron microscope image of the product of this example, it can be known that the obtained product is 150 nm monodisperse colloidal particles. Depend on figure 1 The transmission electron microscope image of a single particle in the lower right corner shows that ...

Embodiment 2

[0051] Add glucose derivatives gluconic acid and polyvinylpyrrolidone to ethylene glycol to prepare a uniform mixed solution, the concentration of gluconic acid is 9g / L or 13.3g / L, and the concentration of polyvinylpyrrolidone is 100g / L. Then add ferric chloride hexahydrate into the mixed solution, stir until completely dissolved, and the concentration of ferric ion in the solution is 4.6g / L. Finally, sodium hydroxide was added to adjust the pH to 9.0. Then put it into a reaction kettle, seal it and heat it to 220°C, and keep it warm for 12 hours, then cool it down to room temperature, wash and separate it with ethanol for 2 to 3 times, and dry the solid in vacuum to obtain the product. 9g / L and 12g / L the scanning electron microscope morphology of glucose concentration gained product is as follows Figure 7 (9g / L) and Figure 8 (13.3g / L), the particle sizes are 100nm and 220nm respectively.

Embodiment 3

[0053] Add tannic acid and polyvinylpyrrolidone to ethylene glycol to prepare a uniform mixed solution, the concentration of tannic acid is 3.33g / L, and the concentration of polyvinylpyrrolidone is 400g / L. Then add ferric chloride hexahydrate into the mixed solution, stir until completely dissolved, and the concentration of ferric ion in the solution is 4.1g / L or 8.6g / L. Finally, anhydrous sodium acetate was added to adjust the pH to 9.0. Then put it into a reaction kettle, seal it and heat it to 200°C, and keep it warm for 24 hours, then cool it down to room temperature, wash and separate it with ethanol for 2 to 3 times, and dry the solid in vacuum to obtain the product. 4.1g / L and 8.6g / L the scanning electron microscope morphology of the product obtained by ferric ion concentration is as follows Figure 9 (4.1g / L) and Figure 10 (8.6g / L), the particle sizes are 90nm and 230nm respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com