Rotary dividing device

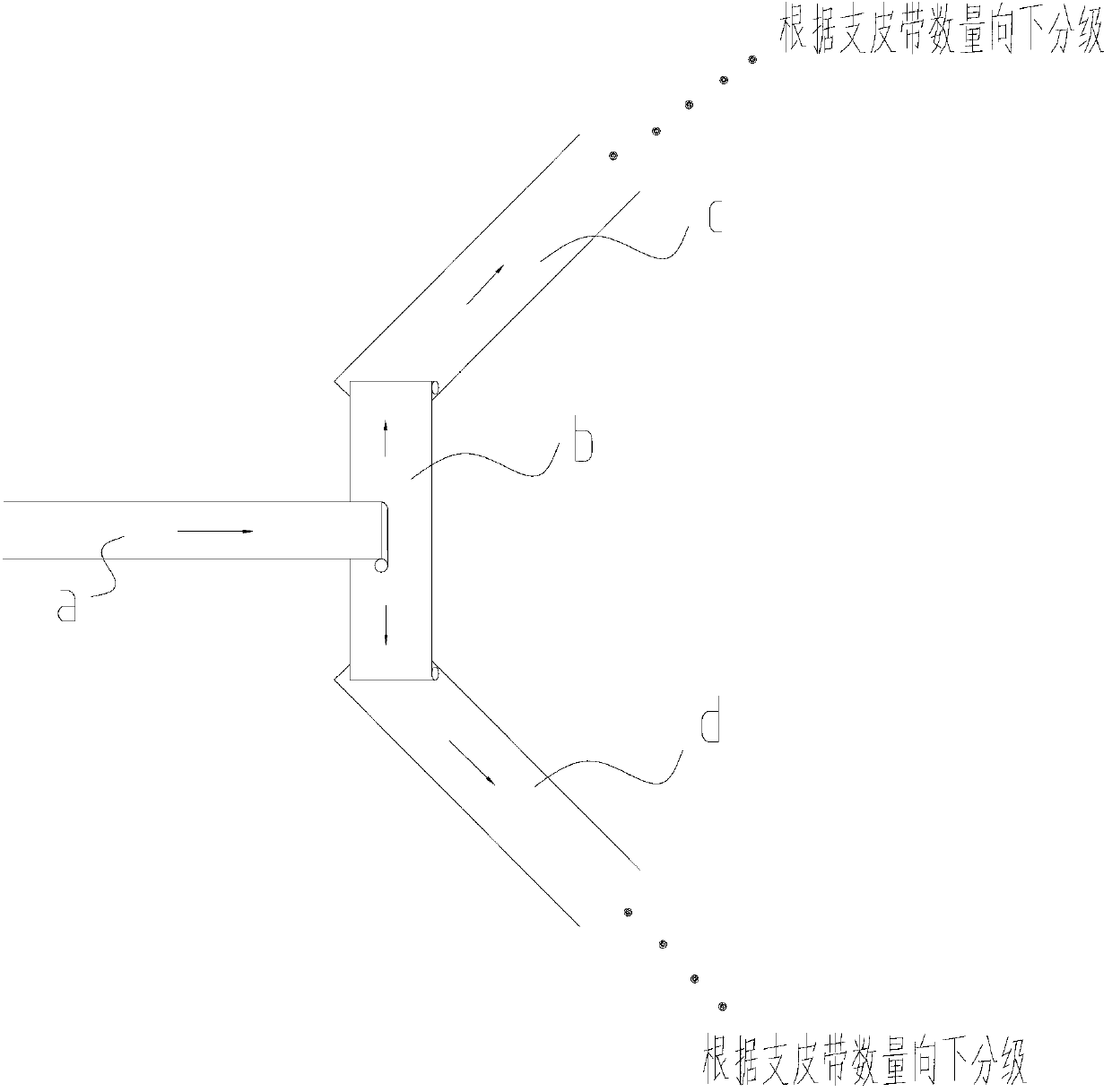

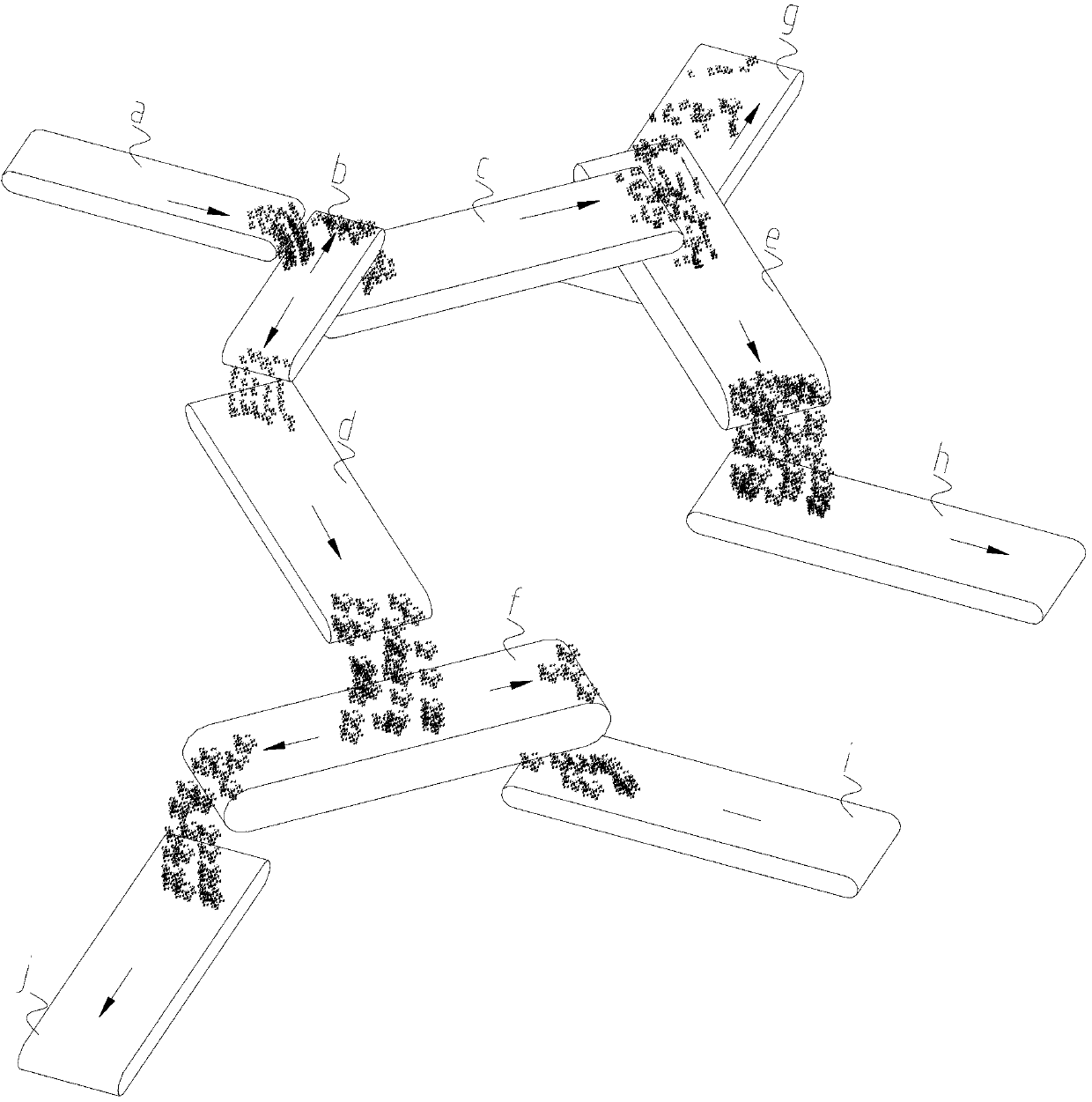

A technology of distributing device and rotating sleeve, which is applied in the direction of transportation and packaging, conveyor objects, etc., which can solve the problems of large space and site, difficult inspection and maintenance, and large number of belt conveyors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In the following, the present invention will be specifically described through exemplary embodiments. It should be understood, however, that elements, structures and characteristics of one embodiment may be beneficially incorporated in other embodiments without further recitation.

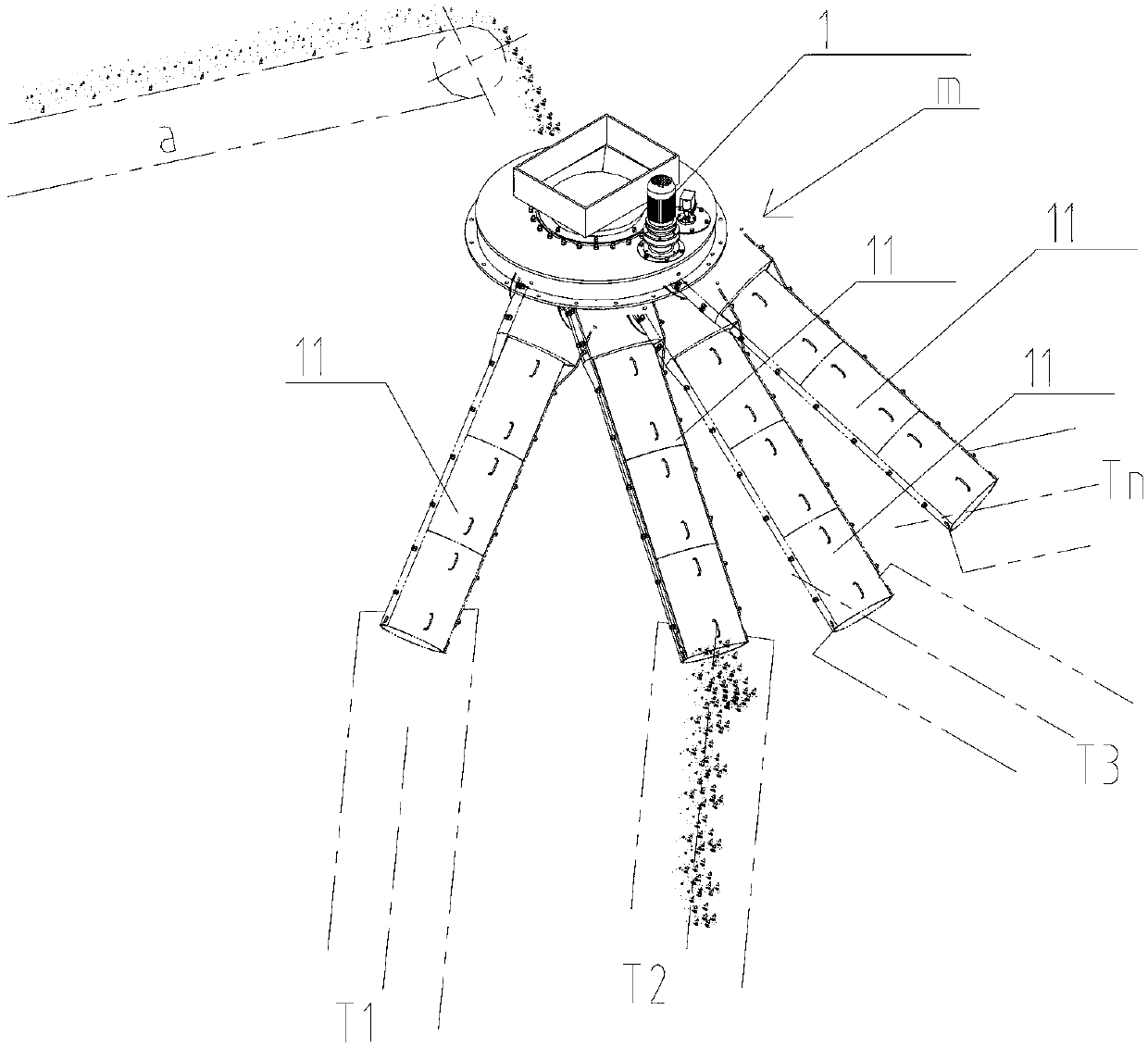

[0027] Such as image 3 , which shows the rotary distribution device m according to the present invention. The rotary distributing device m is used to cooperate with the main belt conveyor to distribute the material to several lowest-level belt conveyors, and has a box body 7 on which a receiving hopper 6 is also arranged.

[0028] It is worth pointing out that the rotary material distribution device m also includes a rotary motor 1 connected above the box body 7 ; and a chute 11 connected to the lower side of the box body 7 . The chute 11 can be driven by the rotary motor 1 to perform circular rotation around the center of the box body 7 . The lower end of the chute 11 can be parked on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com