Green-scraping and polishing machine

A technology of polishing machine and machine body, which is applied in mechanical equipment, plant material machining, etc. It can solve the problems of unsuitable bamboo scraping and other problems, and achieve the effect of protection from damage, prolonging service life, good scraping and polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

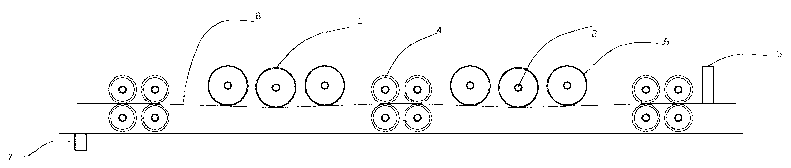

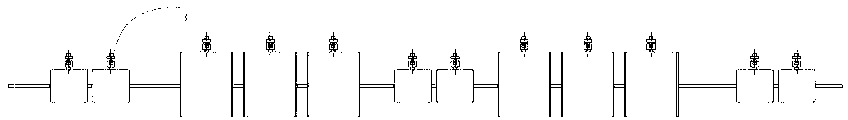

[0019] Such as figure 1 with figure 2 As shown, the scraping and polishing machine includes a body on which feeding wheels 4 for clamping and transporting bamboo chips 8 are symmetrically arranged, and an air drum 1 is arranged between adjacent two groups of feeding wheels 4, and the air drum 1 surrounds Grinding parts 6 are provided, and the grinding parts 6 are sand skins. The central axis of the air drum 1 is provided with a roller 2 that drives the air drum 1 to rotate and is fixed on the body. The height of two adjacent rollers 2 from the horizontal plane of the body is Different, the high and low rollers 2 are used to drive the grinding parts 6 to scrape and polish the bamboo chips 8 arranged at the bottom of the air drum 1, and the feeding wheel 4 and one end of the roller 2 are provided with a universal joint 3; fixed on the body The water pipe inlet 5 that is used to make water flow to the bamboo chip 8 on scraping and polishing is provided with; There are three gro...

Embodiment 2

[0021] Such as figure 1 with figure 2 As shown, the scraping and polishing machine includes a body on which feeding wheels 4 for clamping and transporting bamboo chips 8 are symmetrically arranged, and an air drum 1 is arranged between adjacent two groups of feeding wheels 4, and the air drum 1 surrounds Grinding parts 6 are provided, and the grinding parts 6 are sand skins. The central axis of the air drum 1 is provided with a roller 2 that drives the air drum 1 to rotate and is fixed on the body. The height of two adjacent rollers 2 from the horizontal plane of the body is Different, the high and low rollers 2 are used to drive the grinding parts 6 to scrape and polish the bamboo chips 8 arranged at the bottom of the air drum 1, and the feeding wheel 4 and one end of the roller 2 are provided with a universal joint 3; fixed on the body The water pipe inlet 5 that is used to make water flow to the bamboo chip 8 on scraping and polishing is provided with; There are three gro...

Embodiment 3

[0023] Such as figure 1 with figure 2 As shown, the scraping and polishing machine includes a body on which feeding wheels 4 for clamping and transporting bamboo chips 8 are symmetrically arranged, and an air drum 1 is arranged between adjacent two groups of feeding wheels 4, and the air drum 1 surrounds Grinding parts 6 are provided, and the grinding parts 6 are sand skins. The central axis of the air drum 1 is provided with a roller 2 that drives the air drum 1 to rotate and is fixed on the body. The height of two adjacent rollers 2 from the horizontal plane of the body is Different, the high and low rollers 2 are used to drive the grinding parts 6 to scrape and polish the bamboo chips 8 arranged at the bottom of the air drum 1, and the feeding wheel 4 and one end of the roller 2 are provided with a universal joint 3; fixed on the body The water pipe inlet 5 that is used to make water flow to the bamboo chip 8 on scraping and polishing is provided with; There are three gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com