Welding fixture for welding blade on rotor

A technology for welding tooling and rotors, applied in welding equipment, manufacturing tools, resistance welding equipment, etc., can solve problems such as accurate positioning of blades, achieve the effects of ensuring welding accuracy, improving welding quality, and shortening positioning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

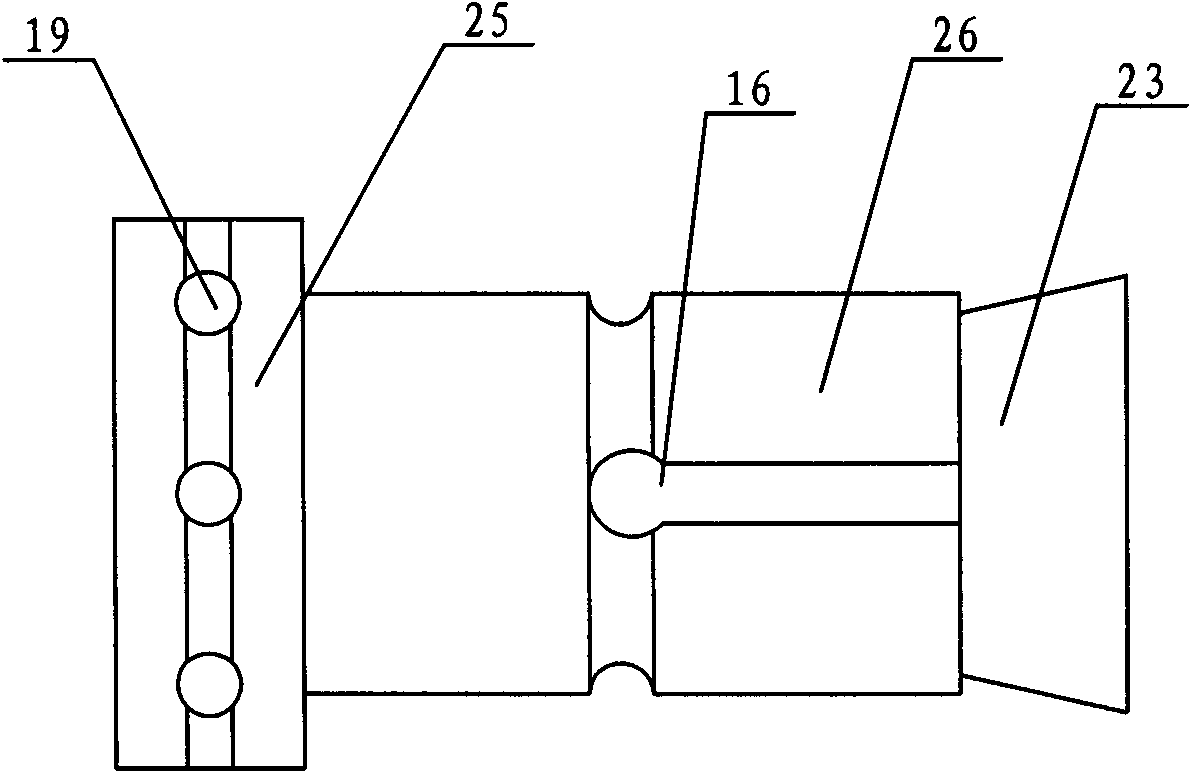

[0015] The invention provides a welding tool for welding the blades on the rotor (see figure 1 with 2 ), including a copper first electrode 11 and a second electrode 12, the first electrode 11 includes a fixed seat 13, a rotating disk 14 and a rotor bearing seat 15 arranged in sequence, and the rotating disk 14 is sleeved on the rotor bearing seat 15 and is connected with The fixed connection, the bump 25 at the front end of the rotor bearing base 15 is inserted into the fixing base 13, the rotor bearing base 15 rotates around the fixing base 13, the diameter of the bearing end 26 at the rear end of the rotor bearing base 15 matches the inner diameter of the rotor, and the bearing end 26 A positioning slot 16 for positioning the rotor is provided on the outer circle of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com