Assembling installing method for express cabinet

An assembly and installation technology, applied in the direction of auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high welding technology requirements, increased labor intensity, and low efficiency, so as to increase labor intensity and scrap The effect of high rate and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] As a preferred embodiment of the present invention, this embodiment discloses a method for assembling and installing express cabinets, the steps of which are as follows: first assemble and assemble the boards of the express cabinet; then weld the joints between the boards; The above-mentioned overall assembling and assembling of express cabinet boards first refers specifically to: assembling the prepared express cabinet boards together according to specific specifications, and fixing the assembled express cabinets through fixing frames; welding the joints between the boards specifically It refers to: welding the joints between the plates of the assembled express cabinet fixed by the fixing frame.

[0021] The invention discloses a method for assembling and installing an express cabinet. Compared with the prior art, the mainstream of the production process and method of the existing express cabinet is manual welding and small and simple chemical equipment. In this case, t...

Embodiment 2

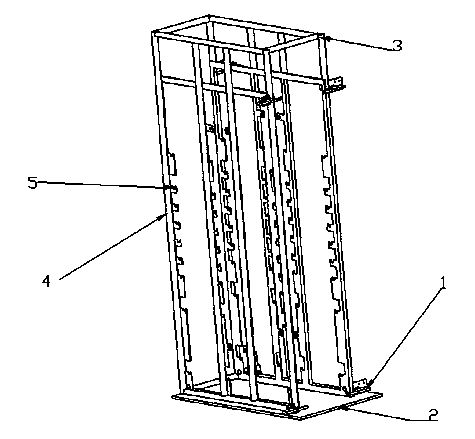

[0023] As a preferred embodiment of the present invention, with reference to the attached figure 1 , the present embodiment discloses a method for assembling and installing an express cabinet, the steps of which are: first assembling and assembling the boards of the express cabinet; then welding the joints between the boards; Assembling and assembling specifically refers to: assembling the prepared express cabinet plates together according to specific specifications, and the assembled express cabinets are fixed by the fixing frame; welding the joints between the plates specifically refers to: fixing the express cabinet through the fixing frame Weld the joints between the plates of the assembled express cabinet.

[0024] The invention discloses a method for assembling and installing an express cabinet. Compared with the prior art, the mainstream of the production process and method of the existing express cabinet is manual welding and small and simple chemical equipment. In thi...

Embodiment 3

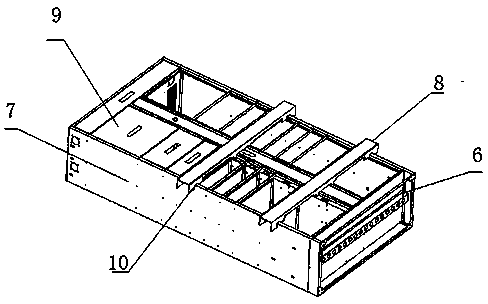

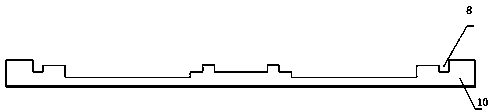

[0028] As a preferred embodiment of the present invention, with reference to the attached figure 2 , the present embodiment discloses a method for assembling and installing an express cabinet, the steps of which are: first assembling and assembling the boards of the express cabinet; then welding the joints between the boards; Assembling and assembling specifically refers to: assembling the prepared express cabinet plates together according to specific specifications, and the assembled express cabinets are fixed by the fixing frame; welding the joints between the plates specifically refers to: fixing the express cabinet through the fixing frame Weld the joints between the plates of the assembled express cabinet.

[0029] The invention discloses a method for assembling and installing an express cabinet. Compared with the prior art, the mainstream of the production process and method of the existing express cabinet is manual welding and small and simple chemical equipment. In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com