Sand mixing process for molding clay green sand

A technology of green sand and moulding sand, which is applied to manufacturing tools, machinery for cleaning/processing of moulding materials, and casting moulding equipment, etc., can solve problems such as control and unsatisfactory use effect, improve moulding quality and save production costs , to ensure the effect of comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Put 2501Kg of old sand with a water content of 1.77% and a temperature of 32°C, without adding new sand, 18.3Kg of bentonite, and 4.8Kg of coal powder, into the Erich RV23 rotor sand mixer, and dry mix for 10 seconds. Add 36.4Kg of water while wet mixing for 95 seconds.

[0028] (2) The testing data of molding sand are shown in Table 2 and Table 3.

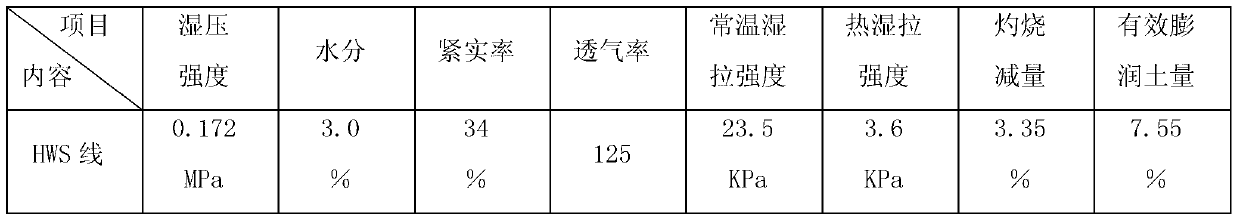

[0029] Table 2 Molding sand testing data of Erich RV23 sand mixer

[0030]

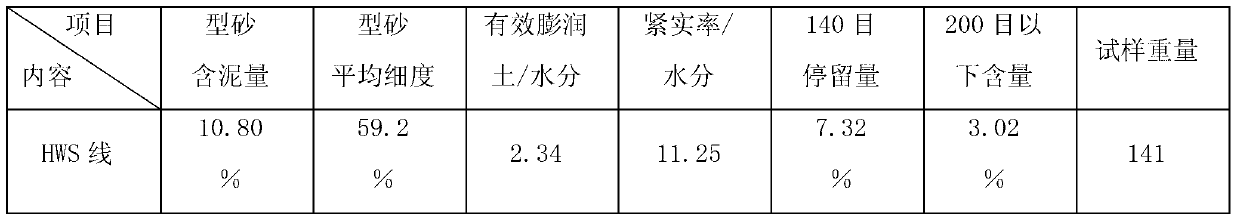

[0031] Table 3 Molding sand testing data of Erich RV23 sand mixer

[0032]

[0033] (3) The mold sand that has been mixed and milled and passed the inspection is used on the HWS line for the molding and casting of the exhaust pipe, and the casting sand and air hole rejection rate is low. Since the exhaust pipe uses more cores, and when mixing the molding sand, the addition of 1.2% new sand is changed to no new sand, which not only reduces the amount of bentonite added, but also reduces the amount of pollutant discharge.

Embodiment 2

[0035] (1) Put 2402Kg of old sand, 25.1Kg of new sand, 23.7Kg of bentonite, and 9.8Kg of coal powder with a moisture content of 2.04% and a temperature of 20.8°C into the Erich RV24 rotor sand mixer, and dry mix for 15 seconds. Add 32.8Kg of water while wet mixing for 100 seconds.

[0036] (2) The testing data of molding sand are shown in Table 4 and Table 5.

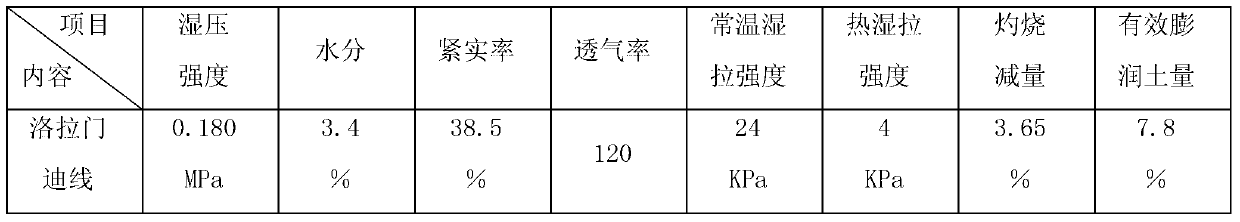

[0037] Table 4 Molding sand testing data of Erich RV24 sand mixer

[0038]

[0039] Table 5 Molding sand testing data of Erich RV24 sand mixer

[0040]

[0041] (3) The molding sand that has been mixed and rolled and passed the inspection is used for the molding and casting of the brake caliper shell on the Loramendi line. Due to the high strength of the molding sand, suitable mud content, good plasticity and toughness, the following bentonite / water is suitable , The compaction rate / water is moderate, the sand mold cracks after pouring 4 cases, and delays to 11 cases after pouring, and the crack width decreases....

Embodiment 3

[0043] (1) Put 1802Kg of old sand, 10Kg of new sand, 20.2Kg of bentonite, and 4.8Kg of coal powder with a water content of 1.5% and a temperature of 27.6°C into the Erich DEV22 rotor sand mixer, and dry mix for 15 seconds. Add 28.1Kg of water while wet mixing for 120 seconds.

[0044] (2) The testing data of molding sand are shown in Table 6 and Table 7.

[0045] Table 6 Molding sand performance test data of Erich DEV22 sand mixer

[0046]

[0047] Table 7. Molding sand performance test data of Erich DEV22 sand mixer

[0048]

[0049] (3) The molding sand that has been mixed and milled and passed the inspection is used for the molding and casting of bearing caps on the DISA line. The rejection rate of casting sand and pores has decreased by about 30% compared with the same period (accounting for the total rejection rate).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mana absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com