Test sample preparation method of tobacco pectin content detection

A sample preparation and tobacco technology, which is applied in the field of sample preparation for the detection of tobacco pectin content, can solve problems such as interference in color development, interference in measurement results, and cumbersome procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The sample preparation method of tobacco pectin content detection of the present invention comprises the following steps:

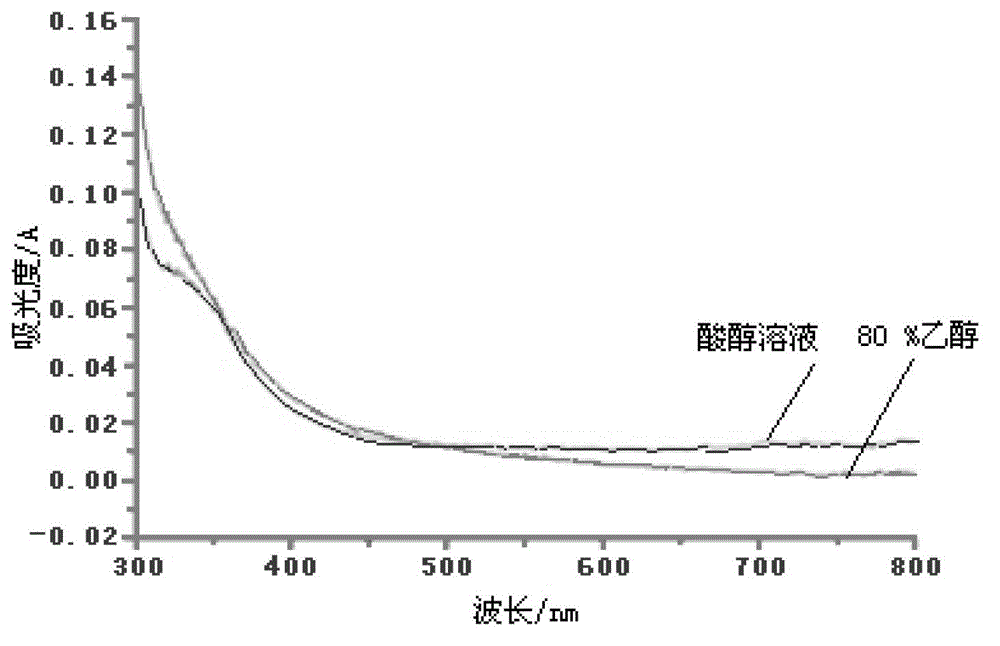

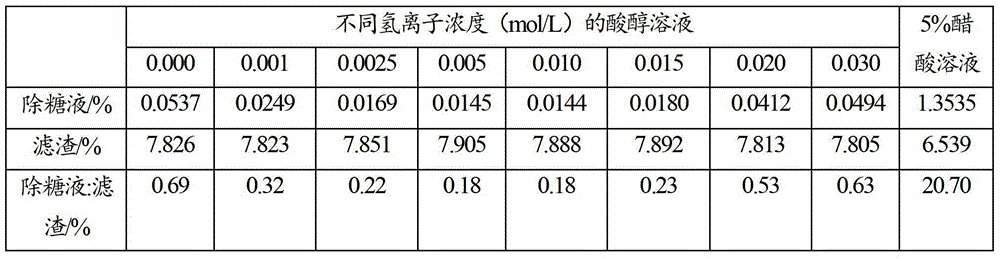

[0037] 1) Add the tobacco sample into the pretreatment liquid, heat and reflux in a water bath at 90°C to 100°C for 10 to 30 minutes, the pretreatment liquid has a hydrogen ion concentration of 0.005mol / L to 0.015mol / L and an alcohol volume concentration of 75% to 85% acid alcohol solution;

[0038] 2) Then use glass fiber filter paper for initial filtration, and rinse the filter residue from the initial filtration with acid alcohol solution;

[0039] 3) Add the rinsed filter residue to the extract solution with a hydrogen ion concentration of 0.75mol / L-1.25mol / L, and heat to reflux in a water bath at 80°C-100°C for 1.51h-2.53h;

[0040] 4) Then carry out secondary filtration, rinse the filter residue after secondary filtration with acid solution for several times, then combine the filtrate after secondary filtration with the rinsing solution and ...

Embodiment 1

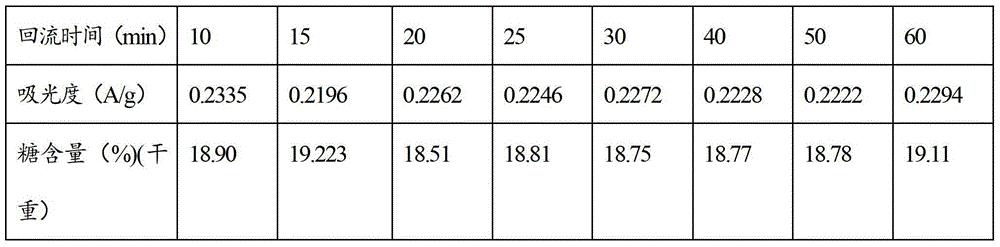

[0044] 1) Add the powdered tobacco sample into the pretreatment solution, and heat and reflux in a water bath at 100°C for 10 minutes;

[0045] 2) Then use glass fiber filter paper for primary filtration, and rinse the filter residue of the primary filtration with acid alcohol solution for several times;

[0046] 3) Add the rinsed filter residue to the extract solution with a hydrogen ion concentration of 1.25mol / L, and heat to reflux in a water bath at 100°C for 1.5h;

[0047] 4) Then use glass fiber filter paper for secondary filtration, rinse the filter residue after secondary filtration with acid solution for several times, then combine the filtrate and rinse solution, and constant volume to obtain the sample to be tested.

[0048] Wherein, the pretreatment solution is an acid-alcohol solution, the hydrogen ion concentration of the acid-alcohol solution is 0.005mol / L, and the alcohol concentration of the acid-alcohol solution is 75% in volume percentage.

Embodiment 2

[0050] 1) Add the powdered tobacco sample into the pretreatment solution, and heat and reflux in a water bath at 90°C for 20 minutes;

[0051] 2) Then use glass fiber filter paper for primary filtration, and rinse the filter residue of the primary filtration with acid alcohol solution for several times;

[0052] 3) Add the rinsed filter residue to the extract solution with a hydrogen ion concentration of 0.9mol / L, and heat to reflux in a water bath at 90°C for 2.5h;

[0053] 4) Then use glass fiber paper for secondary filtration, rinse the filter residue after secondary filtration with acid solution for several times, then combine the filtrate and rinse solution, and constant volume to obtain the sample to be tested.

[0054] Wherein, the pretreatment solution is an acid alcohol solution, the hydrogen ion concentration of the acid alcohol solution is 0.01mol / L, and the alcohol concentration of the acid alcohol solution is 80% in volume percentage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com