Combined steel ball testing platform

A test platform and combined platform technology, applied in impact testing, machine/structural component testing, measuring devices, etc., can solve the problem of failure to meet the testing requirements of steel ball users, ignoring the shape and structure of steel ball test brackets and drop pipes, and steel balls. The ball affects the efficiency of the test and other issues to achieve the effect of convenient structure, improved quality and improved efficiency

Inactive Publication Date: 2013-10-02

WUXI MINGZHU STEEL BALL

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Among them, the steel ball drop equipment is a special equipment used by the steel ball production enterprise to ensure the quality and service life of the steel ball product for the drop test. The existing similar equipment generally uses chain lifting and other conveying devices, while ignoring the steel ball. The shape and structure of the test bracket and the drop pipe, for example, these structures can only smoothly send the steel ball from the bottom of the conveying equipment to the top point to be dropped, which makes all steel balls have only one detection method, that is, one pipe , a height and the same number of drops, which cannot meet the different detection requirements of steel ball users

At the same time, because the equipment only passes the test of one pipe, it is easy to affect the efficiency of the test due to the different specifications of the steel balls

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Login to View More

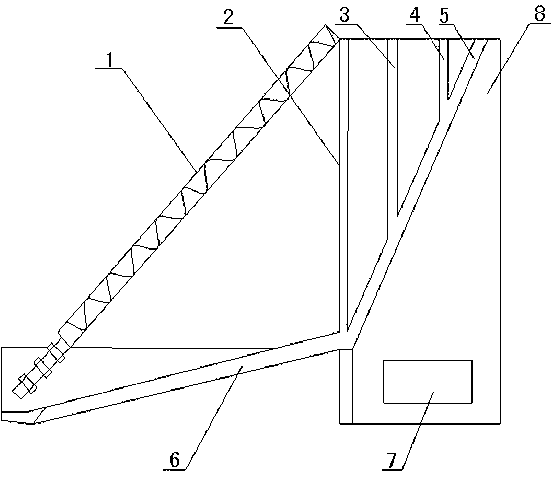

Abstract

The invention discloses a combined steel ball testing platform. The combined steel ball testing platform comprises a spiral elevator and three dropping straight pipes, wherein a combined platform is installed outside the spiral elevator; the three dropping straight pipes with different heights are sequentially arranged from the left side to the right side of the combined platform; the lower ends of the dropping straight pipes are communicated with an inclined guiding slot formed inside the combined platform respectively; an opening at the lower end of the inclined guiding slot is communicated with a bottom slideway. The combined steel ball testing platform has the advantages as follows: through arrangement of the dropping pipes with corresponding sizes and the steel ball runway, conditions for a relevant drop test are met, requirements of steel balls with different specifications can be met, a separate test is facilitated, the steel ball drop test can be ensured to be smooth, and the combined steel ball testing platform is applicable to the drop test on the steel balls with different diameter ranges; a conveying operation is completed through the spiral elevator, so that the efficiency of an on-site test on the steel balls with different specifications is improved.

Description

technical field The invention relates to the technical field of steel ball testing equipment, in particular to a combined steel ball testing platform. Background technique Steel balls are widely used in bearings, hardware, electronics, iron art, mechanical equipment, electric power, mining, metallurgy and other fields. . The post-process of steel ball production is automatic cleaning of steel balls, appearance inspection (rejecting unqualified products), rust prevention, counting and packaging, all of which are the key to the quality of steel balls. The appearance inspection of steel balls mainly includes surface scratches, rust, surface Detection of spots etc. Among them, the steel ball drop equipment is a special equipment used by the steel ball production enterprise to ensure the quality and service life of the steel ball product for the drop test. The existing similar equipment generally uses chain lifting and other conveying devices, while ignoring the steel ball. Th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01M7/08G01N3/303

Inventor 吴昊

Owner WUXI MINGZHU STEEL BALL

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com