Method for preparing SrHfO3:Ce super-microsphere luminescent powder by adopting monohydric alcohol thermal method

A technology of luminescent powder and monohydric alcohol, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of uneven grain size distribution, difficult control of powder shape, uneven doping of activators, etc., and achieve the goal of preparing The effect of short cycle, wide application value and controllable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

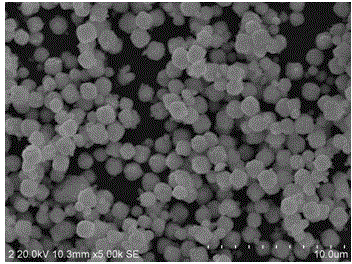

[0020] According to the preparation process, the Sr(NO 3 ) 2 and HfOCl 2 8H 2 O was dissolved in 10ml of deionized water, stirred with a magnetic stirrer, and then 0.3mol% Ce(NO 3 ) 3 , under the situation of constant stirring, add 20ml absolute ethanol, namely solvent V (C 2 h 5 OH):V(H 2 O) is 2:1, add mineralizer KOH, adjust the pH value to 13.5, the solution becomes turbid, stir for a period of time, put it into a 50ml reaction kettle, the filling degree is 70%-80%, adjust the temperature at 140°C and keep it for 4 hours A white precipitate was obtained, which was filtered, washed several times with absolute ethanol, and then dried in a vacuum oven at 80°C for 24 hours to obtain a white powder, which was ground and sieved to obtain a sample. XRD analysis was carried out on samples obtained under different hydrothermal temperatures and different holding times. SEM analysis is carried out on the morphology of the obtained samples, and the powder morphology and partic...

Embodiment 2

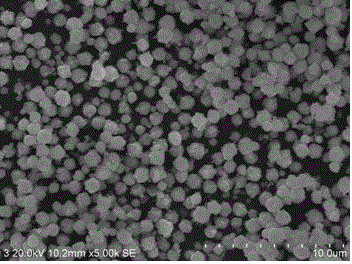

[0022] Change the solvent volume content so that V(C 2 h 5 OH):V(H 2 O) is 3:1, that is, Sr(NO 3 ) 2 and HfOCl 2 8H 2 O is dissolved in the deionized water of 7.5ml, and other conditions are as embodiment 1, and the appearance of gained powder is as follows figure 2 As shown, the powder is nearly spherical, the agglomeration is not obvious, the particle size distribution is relatively uniform, and the particle size is reduced to about 1.0 μm.

Embodiment 3

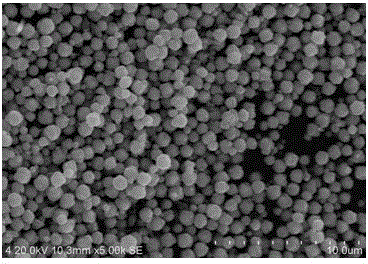

[0024] Change the reaction solvent volume content V(C 2 h 5 OH):V(H 2 O) is 4:1, that is, Sr(NO 3 ) 2 and HfOCl 2 8H 2 O is dissolved in the deionized water of 6ml, other conditions are as embodiment 1, and the appearance of gained powder is as follows image 3 As shown, the powder morphology is uniform spherical, good dispersion, no agglomeration phenomenon, and the particle size is about 800nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com