UV curable coating used for IML, its preparation method and application

A technology of light-curing coatings and photoinitiators, applied in polyester coatings, polyurea/polyurethane coatings, coatings, etc., to reduce production costs, excellent steel wool scratch resistance and stain resistance, and reduce raw material costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

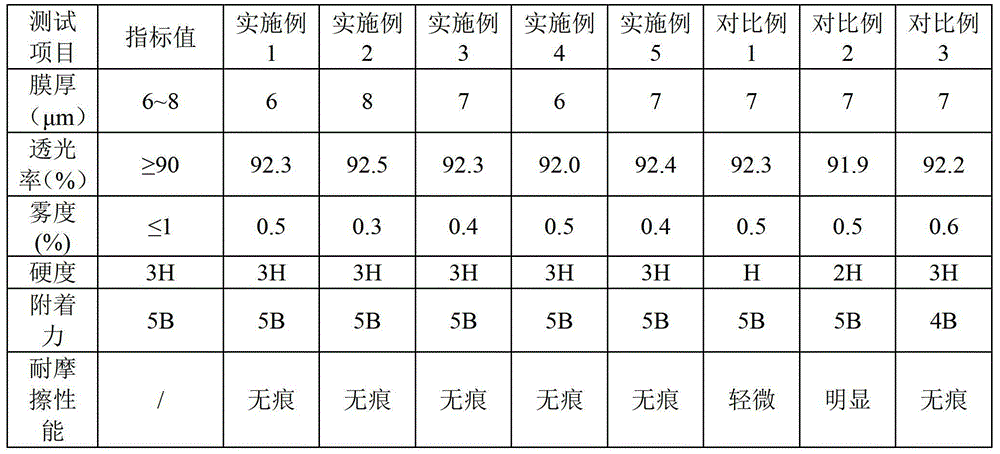

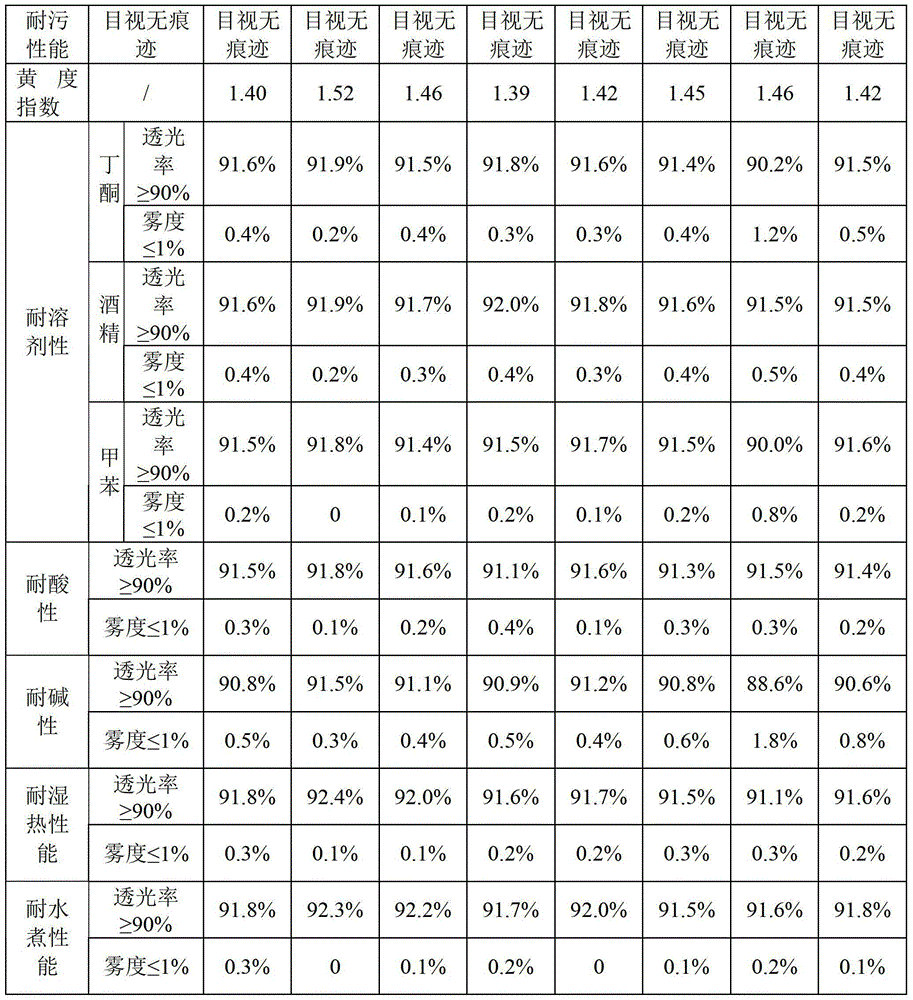

Examples

Embodiment 1

[0032] Preparation of UV curable coatings for IML:

[0033] (1) Combine 4g monofunctional acrylate reactive diluent (Sartomer-SR506NS), 4g hexafunctional acrylate reactive diluent (Eternal-EM265), 0.1g leveling agent (BYK-UV3500) and 70g organic solvent (35g) Butyl acetate and 35g methyl ethyl ketone) mix well;

[0034] (2) Add 10g of aliphatic urethane acrylate (Basf-UA9050) and 10g of hyperbranched polyester acrylate (Sartomer-CN2303) to the mixture obtained in step (1), stir and disperse uniformly;

[0035] (3) Add 1g of silica nanoparticle dispersion (NANOBYK-3650) and 1g of photoinitiator (Irgacure 127) to the mixture obtained in step (2), disperse uniformly, filter, and obtain UV light curable coating for IML .

Embodiment 2

[0037] Preparation of UV curable coatings for IML:

[0038] (1) Combine 10g monofunctional acrylate reactive diluent (Sartomer-SR423NS), 5g tetrafunctional acrylate reactive diluent (Eternal-EM2411), 1g leveling agent (BYK-371) and 50g organic solvent (20g acetic acid) Ethyl acetate, 20g methyl isobutyl ketone and 10g cyclohexanone) are mixed uniformly;

[0039] (2) Add 20g aliphatic urethane acrylate (Cytec-EB8212) and 10g hyperbranched polyester acrylate (Eternal-6361-100) to the mixture obtained in step (1), stir and disperse uniformly;

[0040] (3) Add 2g of alumina nanoparticle dispersion (NANOBYK-3610) and 2g of photoinitiator (Darocur 1173) to the mixture obtained in step (2), disperse uniformly, and filter to obtain a UV curable coating for IML.

Embodiment 3

[0042] Preparation of UV light-curable coatings for IML:

[0043] (1) Combine 4g bifunctional acrylate reactive diluent (Sartomer-SR238NS), 1g hexafunctional acrylate reactive diluent (Eternal-EM267), 0.3g leveling agent (BYK-UV3500) and 60g organic solvent (30g) Butyl acetate and 30g methyl isobutyl ketone) are mixed uniformly;

[0044] (2) Add 17g aliphatic urethane acrylate (Sartomer-CN9013) and 15g hyperbranched polyester acrylate (Eternal-6362-100) to the mixture obtained in step (1), stir and disperse uniformly;

[0045] (3) Add 1.5g of alumina nanoparticle dispersion (NANOBYK-3651) and 1.5g of photoinitiator (Darocur MBF) to the mixture obtained in step (2), disperse uniformly, filter, and obtain UV curing for IML coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com