Degradable reinforced plant fiber material and preparation method thereof

A plant fiber material and plant fiber technology, applied in the field of degradable reinforced plant fiber material and its preparation, can solve the problems of long production cycle, insufficient strength, non-degradable, etc., achieve shortened production time, improve compatibility, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

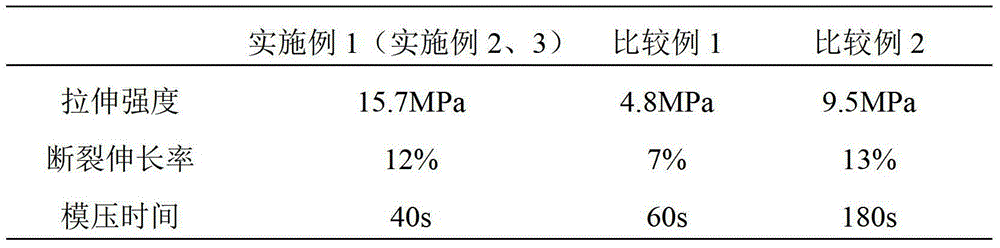

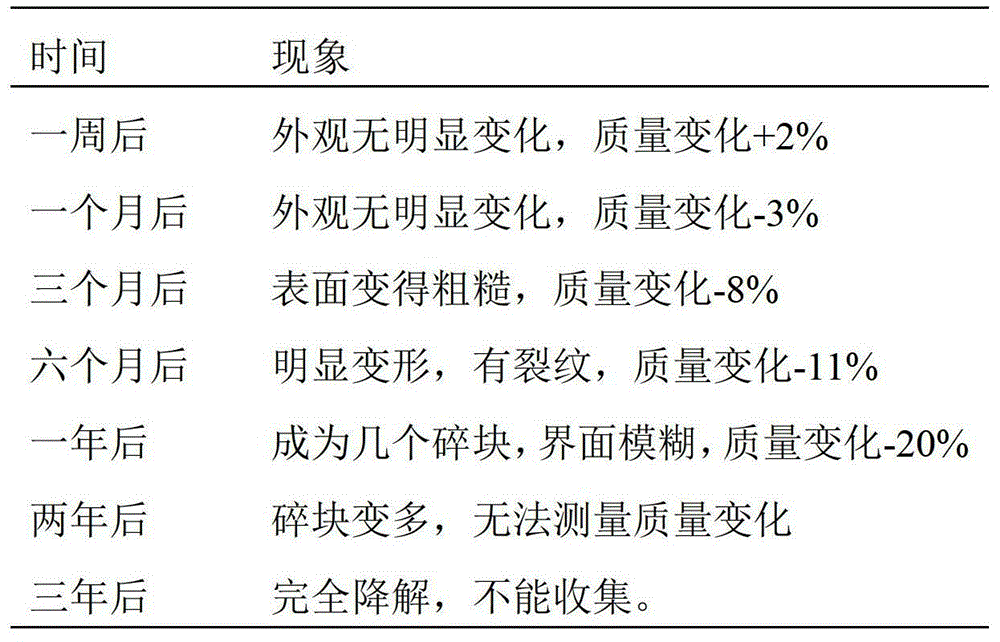

Examples

Embodiment 1

[0033] A degradable reinforced plant fiber material, the plant fiber material is prepared from the following raw materials in weight percentage: rice husk powder 52%, degradable adhesive 14%, reinforcing agent 12.5%, release agent 2%, Water 19.5%, wherein, the degradable adhesive is mixed by weight ratio polyvinyl alcohol: urea-formaldehyde resin=5:2, and the described reinforcing agent is by weight ratio heavy calcium carbonate: nano silicon dioxide= 12:0.5 mixed, the release agent is stearic acid powder;

[0034] The preparation method of the above-mentioned degradable reinforced plant fiber material, the steps are as follows:

[0035] (1) Put 5.2kg of 50-mesh rice husk powder, 1kg of powdered polyvinyl alcohol, 0.4kg of powdered urea-formaldehyde resin, 1.2kg of heavy calcium carbonate, 0.05kg of nano-silica, and 0.2kg of stearic acid in the mixer , Stir for 3 minutes first, then continue to stir and add 1.95kg of water until the mixture is uniform, and prevent agglomerati...

Embodiment 2

[0038] A degradable reinforced plant fiber material, the plant fiber material is prepared from the following raw materials by weight percentage: rice husk powder 51%, degradable adhesive 14%, reinforcing agent 13%, release agent 2%, 20% water, wherein, the degradable adhesive is mixed by weight ratio of polyvinyl alcohol: urea-formaldehyde resin=5:2, and the reinforcing agent is made of weight ratio of heavy calcium carbonate: nano silicon dioxide= 12:1 mixed, the release agent is stearic acid powder;

[0039] The preparation method of the above-mentioned degradable reinforced plant fiber material, the steps are as follows:

[0040] (1) Put 5.1kg of 50-mesh rice husk powder, 1kg of powdered polyvinyl alcohol, 0.4kg of powdered urea-formaldehyde resin, 1.2kg of heavy calcium carbonate, 0.1kg of nano-silica, and 0.2kg of stearic acid in the mixer , Stir for 3 minutes first, then continue to stir and add 2kg of water until the mixture is uniform, and prevent agglomeration during...

Embodiment 3

[0043] A degradable reinforced plant fiber material, the plant fiber material is prepared from the following raw materials by weight percentage: rice husk powder 41.6kg, powdery polyvinyl alcohol 8kg, powdery urea-formaldehyde resin 3.2kg, heavy calcium carbonate 9.6kg kg, nano silicon dioxide 0.4kg, zinc stearate 1.6kg, water 15.6kg.

[0044] The preparation method of the above-mentioned degradable reinforced plant fiber material, the steps are as follows:

[0045] (1) Put 41.6kg of 50-mesh rice husk powder, 8kg of powdery polyvinyl alcohol, 3.2kg of powdery urea-formaldehyde resin, 9.6kg of heavy calcium carbonate, 0.4kg of nano-silicon dioxide, and 1.6 kg of zinc stearate into the mixer in turn. kg, first stir for 3 minutes and then continue to stir and add 15.6kg of water until the mixture is uniform. During the stirring process, agglomeration should be prevented.

[0046] (2) Preheat the molding machine to 110°C, add 50-100g of raw materials into each mold, pressurize at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com